Seebacher GmbH www.seebacher.de Phone: +49 (0) 80 41 / 77 77 6

Marktstrasse 57, 83646 Bad Tölz info@seebacher.de Fax: +49 (0) 80 41 / 77 77 2

3

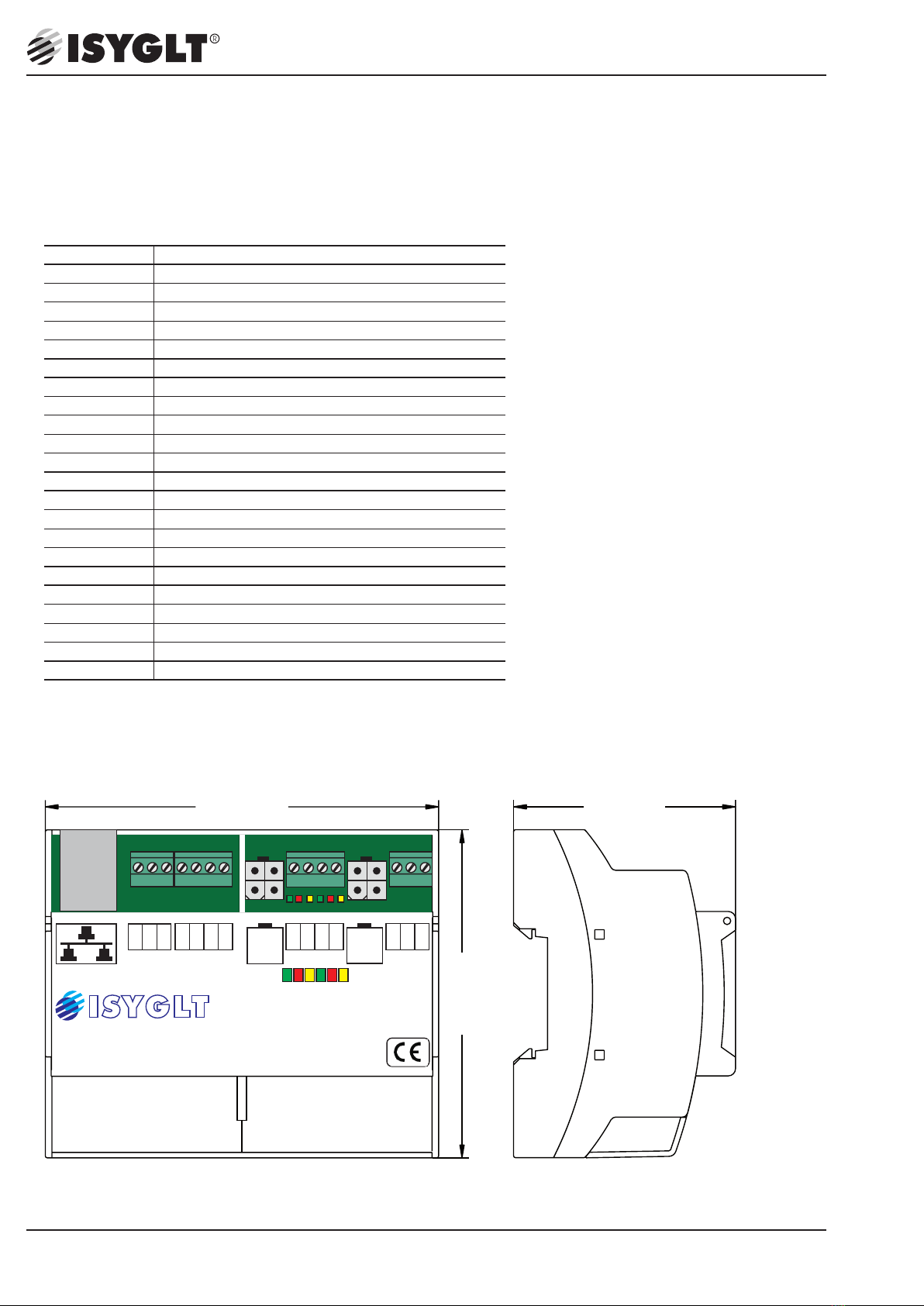

The module is designed for cabinet installation on a 35mm DIN

rail according to EN 60715 in corresponding standard housings.

Extreme environmental conditions impair the function of the pro-

duct.

• Protect module from shocks

• Use module indoors only

• Protect module from humidity

In addition to these safety instructions, you must also observe

the special safety instructions listed in the individual chapters for

the individual acts.

2.4. Qualification of staff

Assembly, commissioning, operation, maintenance, decommis-

sioning and disposal may only be carried out by qualified staff.

Work on electrical parts may only be carried out by a trained

electrician in accordance with the applicable regulations and

directives. Other activities in connection with the ISYGLT module,

such as assembly and installation of system components with

tested standard plug connections, as well as operation and con-

figuration of the ISYGLT module may only be carried out by trai-

ned staff.

2.5. Changes to the product

Unauthorized modifications to the ISYGLT module which are not

described in this or the other applicable instructions can lead to

malfunctions and are prohibited for safety reasons.

2.6. Use of spare parts and additional equipment

The module may be damaged if unsuitable spare parts and addi-

tional equipment are used. Only use original spare parts and

additional equipment from the manufacturer.

2.7. Liability notes

SEEBACHER accepts no liability or warranty whatsoever for

damage and consequential damage caused by non-compliance

with the technical regulations, instructions and recommendati-

ons. SEEBACHER shall not be liable for any costs or damage

incurred by the user or third parties as a result of the use of this

equipment, in particular improper use of the equipment, misuse

or malfunction of the connection, malfunction of the equipment

or connected devices.

SEEBACHER accepts no liability for printing errors.

2. Safety instructions

Observe the following general safety instructions when installing

and commissioning the device:

Assembly and installation of the ISYGLT module may only be carried

out by a qualified electrician. Other activities in connection with the

ISYGLT module, such as assembly and installation of system com-

ponents with tested standard plug connections, as well as operation

and configuration of the ISYGLT module may only be carried out by

trained staff.

Observe the electrical installation regulations of the country in which

the device is installed and operated as well as its national accident

prevention regulations. In addition, observe internal company regu-

lations (work, operating and safety regulations).

Before working on the ISYGLT module system, it must be

disconnected from the power supply and secured against

being switched on again. After completion of the assembly,

installation and maintenance work, an electrical check must

be carried out! Check all protective conductor connections

and the voltages at all connection plugs as well as at each

individual module slot.

2.1. Intended usage

The module is exclusively suitable for regulation (control) in con-

nection with ISYGLT system components. Any other use is not

intended. The limit values stated in the technical data must not be

exceeded under any circumstances. This applies in particular to

the permissible ambient temperature range and the permissible

IP protection type. For applications with a higher required IP pro-

tection type, the ISYGLT module must be installed in a housing

or a cabinet with a higher IP protection type.

2.2. Predictable mishandling

The module must not be used in the following cases in particular:

•explosive area

When operating in explosive areas, sparking can lead to defla-

gration, fire or explosions.

2.3. Safe handling

This module corresponds to the state of the art and the recog-

nised safety regulations. Each device is tested for function and

safety before delivery.

Only operate this module in perfect condition in accordance with

the operating instructions, the applicable regulations and directi-

ves of the country in which the device is installed and operated,

and the applicable safety and accident prevention regulations.