- 7 - Easy Mix Plus - 2018/07 - Rev. 03 EN

SAFETY

When using industrial equipment and plants, one must be aware of the fact that moving parts

(rotarymotion), highvoltage components, aswell as partssubject tohigh temperatures maycause

serious damage to persons and things.

The persons in charge of safety must ensure that:

any incorrect use or handling is avoided;

the safety devices are neither removed nor tampered with;

the machine is regularly serviced;

only original spare parts are used, especially in the case of safety-related components

(e.g.: protection microswitches, thermostats).

suitable personal protective equipment is used;

high care is taken during hot product cycling.

To achieve the above, the following is necessary:

at the work station an instruction manual relevant to the machine should be available;

such documentation must be carefully read and requirements must consequently be met;

only adequately skilled personnel should be assigned to electrical equipment; this appliance is

not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for their safety;

Make sure that no technician will ever carry out interventions outside his/her own knowledge

and responsibility sphere;

Children should be supervised to ensure that they do not play with the appliance.

IMPORTANT!

Make sure that the personnel do not perform operations out of their range of knowledge and

responsibility (refer to “Qualication of the personnel symbols”).

NOTE:

According to the standard in force, a QUALIFIED ENGINEER is a person who, thanks to:

- training, experience and education,

- knowledge of rules, prescriptions and interventions on accident prevention,

- knowledge of machine operating conditions,

It is able to realize and avoid any danger and has also been allowed by the person in charge of

plant safety to carry out all kinds of interventions.

WARNINGS

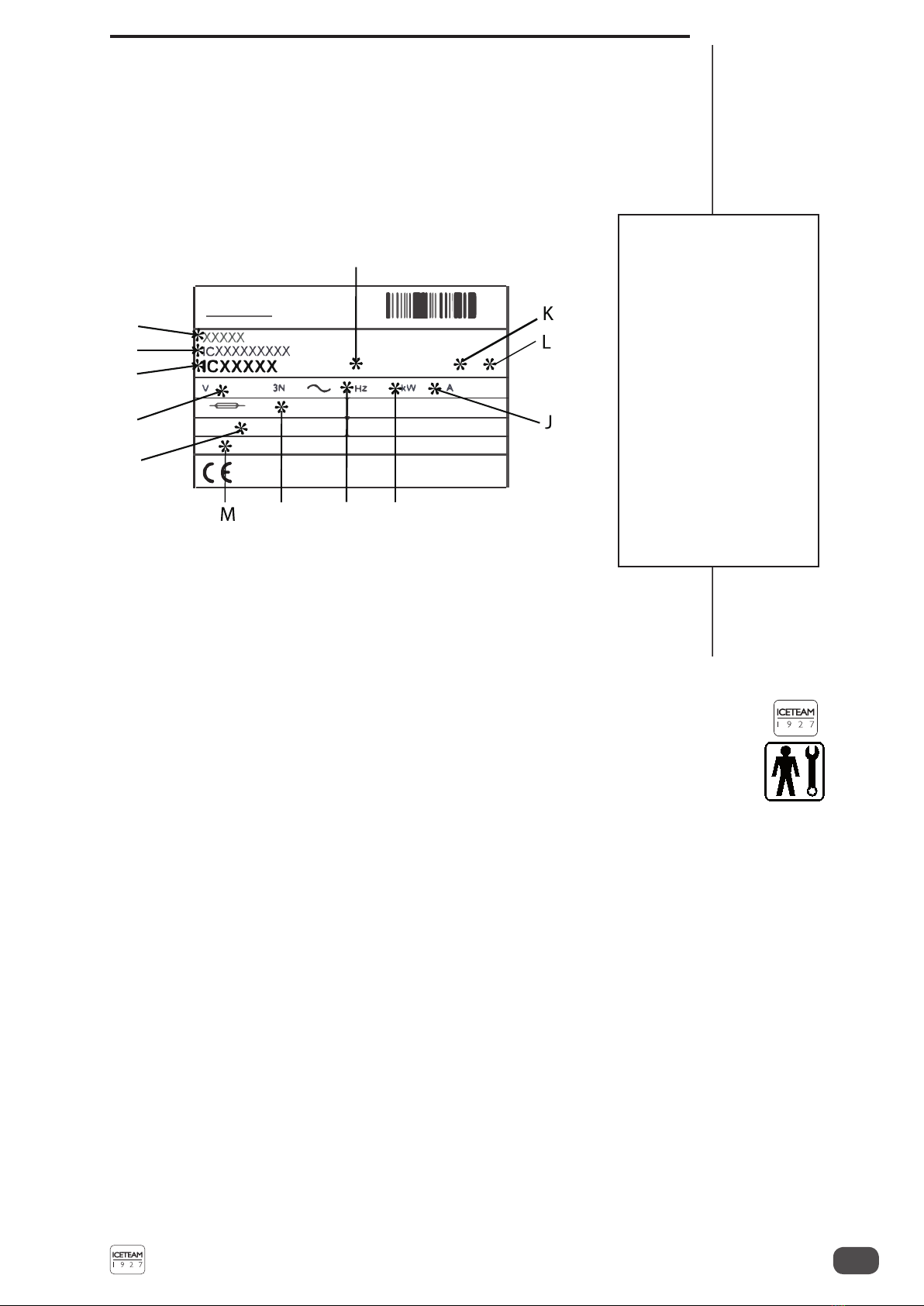

The machine must be installed in compliance with current installation regulations.

When installing the machine, insert a differential magnetothermal protection switch on all poles

of the line, adequately sized to the absorption power shown on machine identication plate and

with a contact opening of 3 mm at least.

Neverperformoperationsonthemachineusingyourhands,duringbothproductionandcleaning.

Beforecarryingoutanymaintenanceoperation,makesurethatthemachineisin“STOP” position

and that the main switch has been cut out.

It is forbidden to wash the machine by means of a jet of pressurized water.

Itisforbiddentoremovepanelsinordertoreachthemachineinternalpartsbeforedisconnecting

the machine from the power supply.

The place of installation must not be exposed to water sprays, high moisture, heat or steam

sources.

Do not store explosive substances or spray cans inside the machine, nor aerosol cans

containing ammable propellant.

ICETEAM 1927 is not responsible for any accident that might happen during operation,

cleaning and/or servicing of its machines if this warning has not been fully complied with.