MINI RECEIVER WITH FIELD BUS

USER MANUAL

1. INTRODUCTION

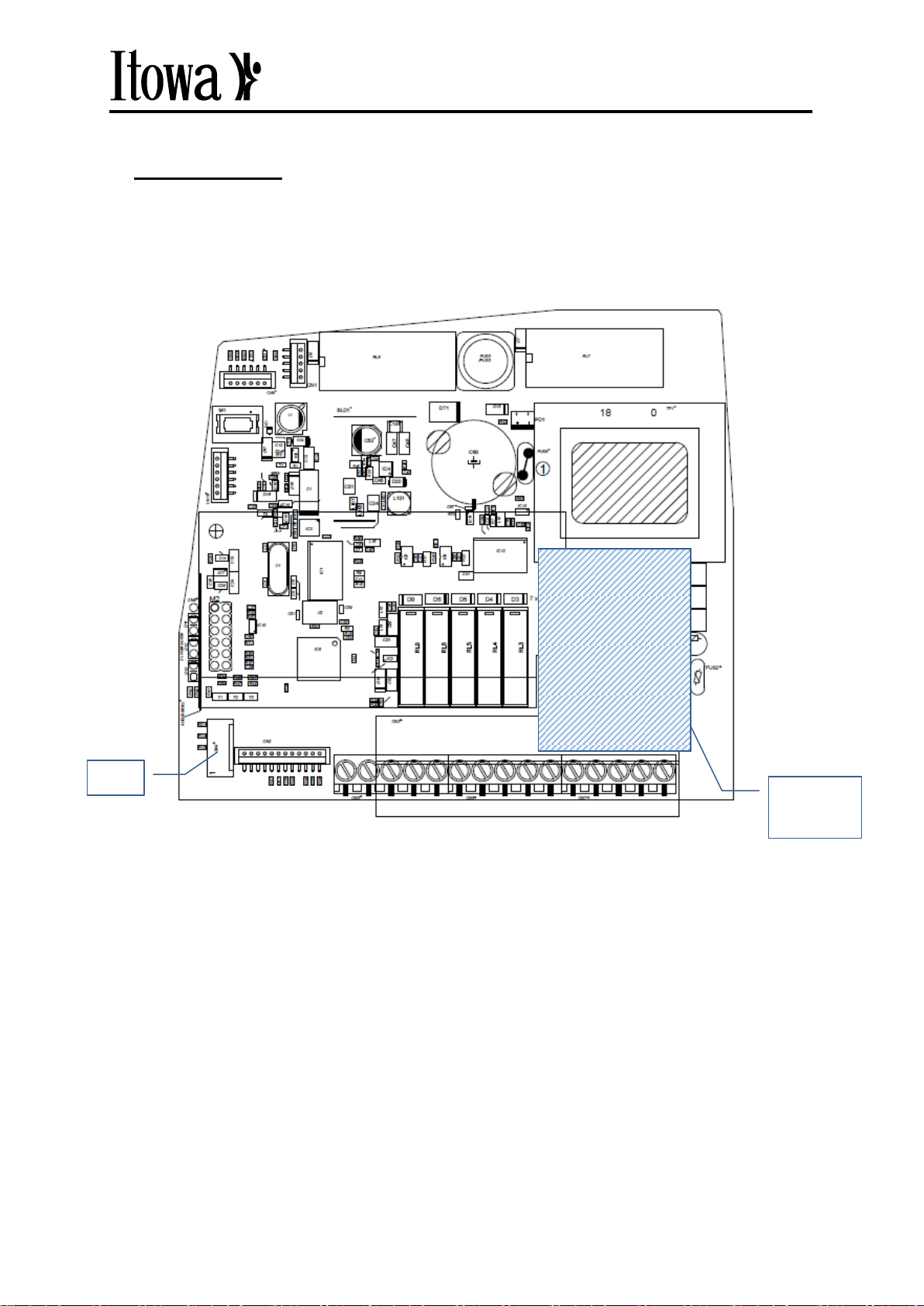

The Mini Receiver, which we will call hereafter Mini RX, has an expansion connector, CN4, which

enables the communication function with a fieldbus module. This module allows establishing links with

different types of bus, among which are: PROFIBUS, CANopen, DeviceNET, PROFINET,

ETHENET/IP and MODBUSTCP. The connection is made through a galvanic isolation and depending

on the type of bus, a different type of output is available in the equipment.

This external connection allows direct communication with a PLC, providing all the available

manoeuvres in the transmitters both at the digital level of contacts and at the analog level of

manipulators. In addition to the transmission of commands to the PLC, the equipment incorporates the

safety relays and allows the auxiliary connection of up to 6 contacts directly to the equipment.

The software, based on the REMOV019a version, allows managing both the configuration and the

communication with the network, adding new functionalities to the receiver, such as the increase of

available manoeuvres and the use of analog channels by copying the full functionality of the

transmitters.

The device configuration file is provided together with the device:

For PROFIBUS, the .gsd file is based on the HMS industrial networks standard for DP-V0 in

slave mode, and will be used later to configure the device within the network through the

master device, usually a PLC. Once configured, the PROFIBUS master will be able to read

the status of the different digital and analogue commands received from the transmitter.

For PROFINET, an .xml file is available which is based on the HMS Industrial Networks

GSDML standard for configuring the slave device on the network.

For the rest of field bus devices, the .eds file contains a description of the device, its functions,

and the object dictionary description that is implemented. This file is used by the network

configuration tools as previously set.