TRIAL OPERATION OF THE MACHINE

After install the machine, upon confirm connect for the steam, electricity and the air activate trial

operation.

1. Open the machine

・ Get rid of the vinyl cover and lapping paper.

・ Get rid of the rectangular timber where fixed the back iron for the body press and left arm.

・ Remove the foot switch to the easy operation at the front part of the machine.

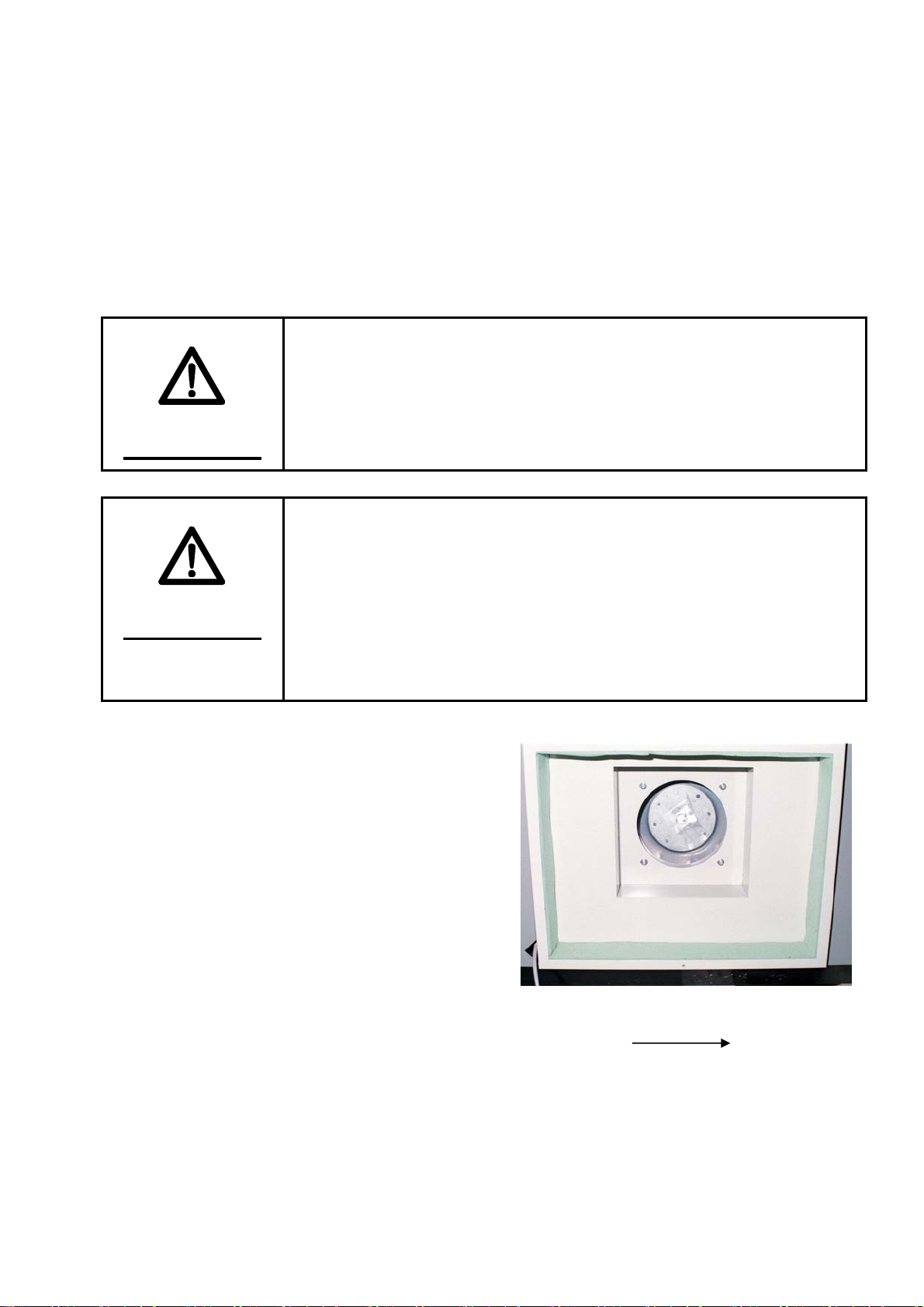

2. SET THE COVER FOR LEFT EDGE OF THE MACHINE.

that the pressure level should be 0.5MPa.

・

peration of the electro-magnetic

4. R

・ eep press stop button more than 2 seconds,

int as regulated turn.

5. O

・move the lapping paper covered on the dummy.

lar timber for fix the collar cramp.

・onnect the breaker for the factory.

e machine when you turn on the power switch of the machine.

Open the steam valve for supply the steam for the machine.

m leakage from the steam circuit.

According to the operating process later on, activate the machines function.

ss w/o shirt when you finish actual shirt.

3. RELEASE THE LOCK CONCERNING THE AIR.

・ Supply the air for the machine and make sure

Status of the body press iron is closed by

manual o

4KB310

valve for body press. For release the body

press iron, remove the manual switch of the

electro-magnetic valve for press from

condition of 「ON」to 「OFF」. Normally it

is available to work 「OFF」status.

ETURN TO THE ORIGIN POINT.

K

each device will move to the origin po

pen the dummy

Re

・ Remove rectangu

6. Connect the power supply

C

・ Check the indication on th

7. Steam Supply

・

・ Check the stea

8. TRIAL OPERATION OF THE MACHINE.

・

・It is necessary to activate 4 or 5 times trial pre

B-4