Outline............................................................................................................................................... 33

Fan Control........................................................................................................................................35

Down sequence.................................................................................................................................36

Power Supply.................................................................................................................................... 37

Outline............................................................................................................................................... 37

Protective Functions............................................................................................................................37

Upgrading..........................................................................................................................................38

Upgrading...........................................................................................................................................38

3. Periodical Service.......................................................................................... 39

List of Work for Scheduled Servicing................................................................................................ 40

4. Disassembly/Assembly................................................................................. 41

Notes at Parts Replacement............................................................................................................. 42

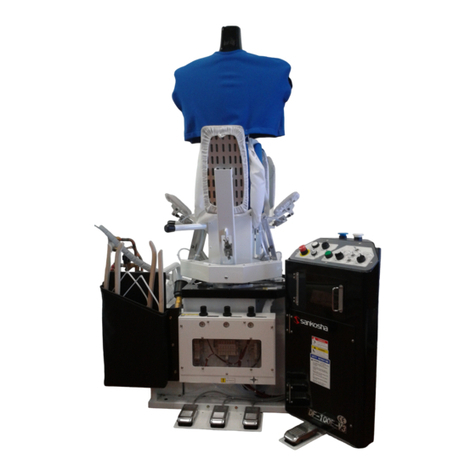

Removing this Machine.....................................................................................................................43

Removing this Machine from the Host Machine.....................................................................................43

List of Parts....................................................................................................................................... 48

External Cover....................................................................................................................................48

List of Main Unit.................................................................................................................................. 48

List of Solenoids..................................................................................................................................49

List of Motors......................................................................................................................................50

List of Fans.........................................................................................................................................51

List of Sensors/Switches......................................................................................................................51

List of PCBs........................................................................................................................................52

Other Parts.........................................................................................................................................53

External Cover...................................................................................................................................54

Removing the Front Cover Unit............................................................................................................ 54

Removing the Rear Cover....................................................................................................................54

Removing the Delivery Tray.................................................................................................................54

Removing the Tray Guide Cover.......................................................................................................... 55

Main Unit........................................................................................................................................... 57

Removing the Upper Feed Guide Unit.................................................................................................. 57

Removing the Processing Tray Unit......................................................................................................58

Removing the Stapler Unit................................................................................................................... 62

Removing the Staple-free Staple Unit...................................................................................................63

Solenoids...........................................................................................................................................64

Removing the Paper Trailing Edge Pushing Guide Solenoid(SL1).......................................................... 64

Motor................................................................................................................................................. 65

Removing the Stapler Shift Motor (M7)................................................................................................. 65

Fan.................................................................................................................................................... 66

Removing the Inlet Coolong Fan (FM1)................................................................................................ 66

PCB...................................................................................................................................................67

Removing the Finisher Controller PCB..................................................................................................67

Sensor...............................................................................................................................................69

Removing the Delivery Sensor(PS1).....................................................................................................69

Other Parts........................................................................................................................................70

Removing the Return Belt Unit.............................................................................................................70

Contents

ii