Power Supply.................................................................................................................................... 37

Outline............................................................................................................................................... 37

Protective Functions............................................................................................................................37

Upgrading..........................................................................................................................................38

Upgrading...........................................................................................................................................38

3. Periodical Service.......................................................................................... 39

List of Work for Scheduled Servicing................................................................................................ 40

4. Parts Replacement and Cleaning................................................................. 41

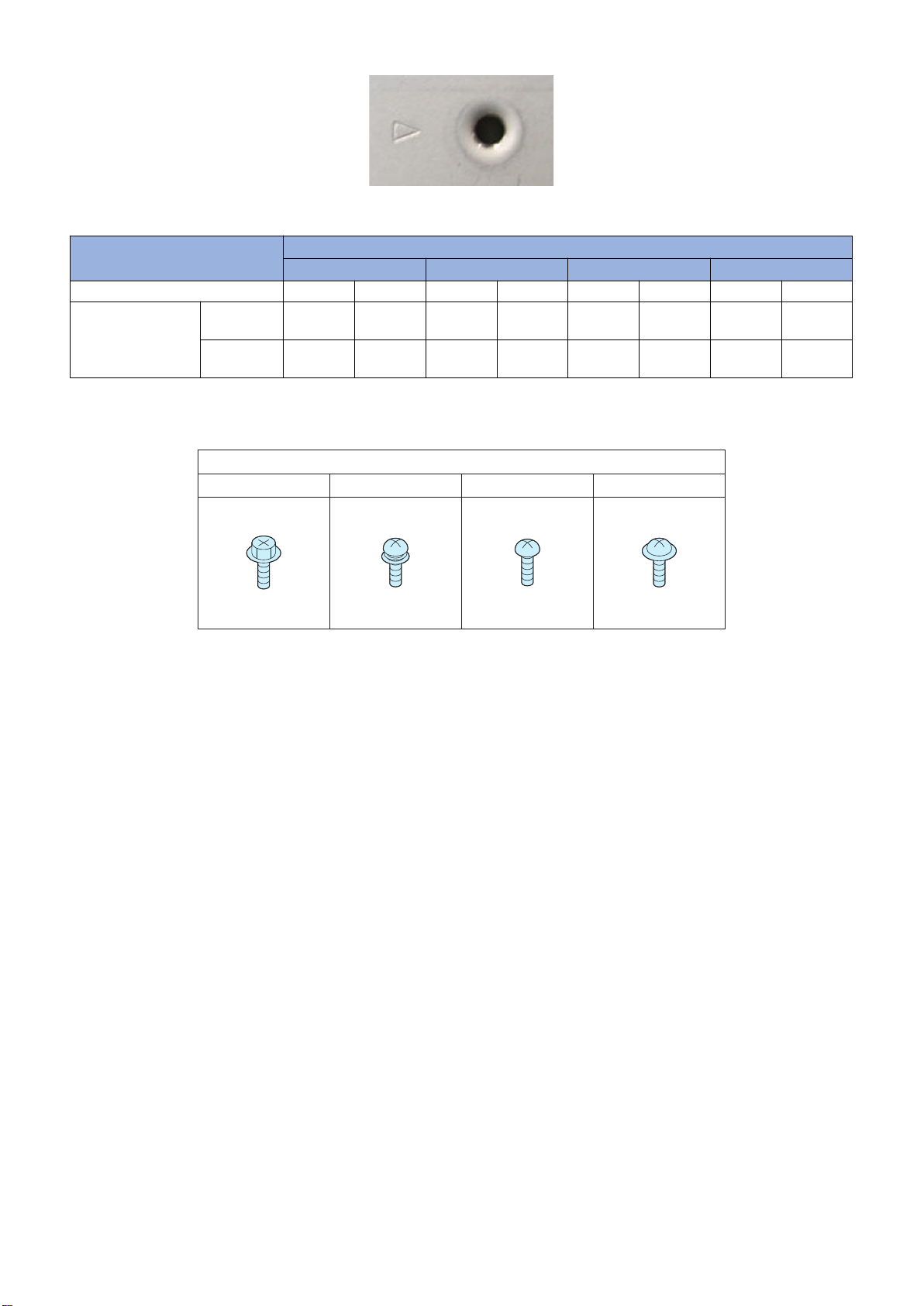

Notes at Parts Replacement............................................................................................................. 42

Illustrations......................................................................................................................................... 42

Removing this Machine from the Host Machine................................................................................43

Removing this Machine from the Host Machine. (In the case of Inner Finisher only).................................43

Removing this Machine from the Host Machine. (In the case of Inner Finisher and Inner Puncher Unit).... 55

List of Parts....................................................................................................................................... 71

External Cover....................................................................................................................................71

List of Main Unit.................................................................................................................................. 71

List of Solenoids..................................................................................................................................72

List of Motors...................................................................................................................................... 73

List of Sensors/Switches......................................................................................................................74

List of PCBs........................................................................................................................................75

Other Parts.........................................................................................................................................75

External Cover...................................................................................................................................76

Removing the Front Cover Unit............................................................................................................ 76

Removing the Rear Cover....................................................................................................................76

Removing the Delivery Tray.................................................................................................................77

Installing the Delivery Tray...................................................................................................................77

Removing the Tray Guide Cover.......................................................................................................... 78

Main Unit........................................................................................................................................... 80

Removing the Upper Feed Guide Unit.................................................................................................. 80

Removing the Processing Tray Unit......................................................................................................81

Removing the Stapler Unit................................................................................................................... 85

Removing the Staple-free Staple Unit................................................................................................... 86

Solenoids...........................................................................................................................................88

Removing the Paper Trailing Edge Pushing Guide Solenoid(SL1).......................................................... 88

Motor................................................................................................................................................. 89

Removing the Stapler Shift Motor (M7)................................................................................................. 89

Removing the Assist Motor (M5).......................................................................................................... 89

Sensor...............................................................................................................................................91

Removing the Delivery Sensor(PS1).....................................................................................................91

Removing the Disengaging Sensor (PS16)........................................................................................... 91

PCB...................................................................................................................................................92

Removing the Finisher Controller PCB (PCB1)......................................................................................92

Other Parts........................................................................................................................................93

Removing the Return Belt Unit............................................................................................................. 93

Contents

ii