5

Dual Phase+ Power Supply 5100636 Rev. F

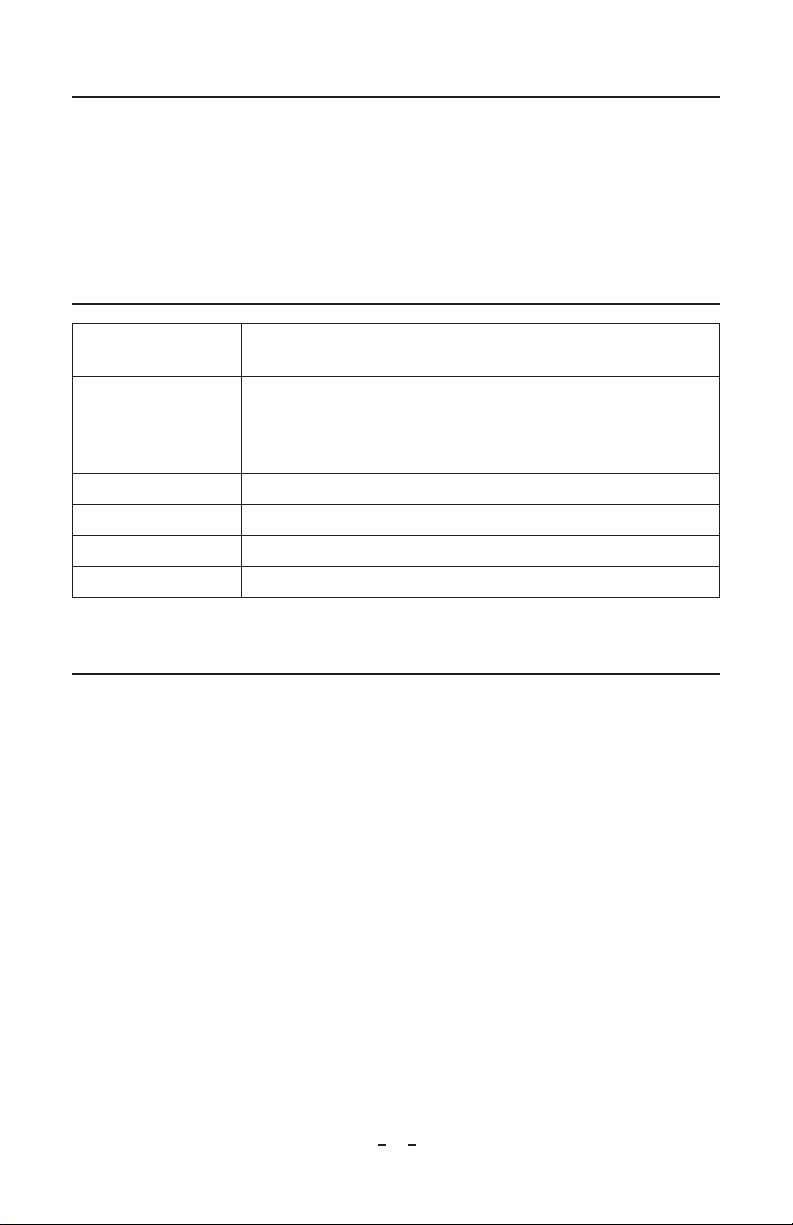

4. Cut the high voltage cable to the desired length. Be sure to allow additional

length to reach the high voltage output terminal blocks inside the power unit’s

case.

5. Strip 3/8” insulation from the end of the high voltage cable and insert the cable

through a straight-through fitting.

6. Loosen one of the connection screws on the high voltage output terminal block.

Insert the stripped end of the cable under the screw and tighten. Tighten the

straight-through fitting until snug. Pull gently on the cable to make certain the

connection is secure.

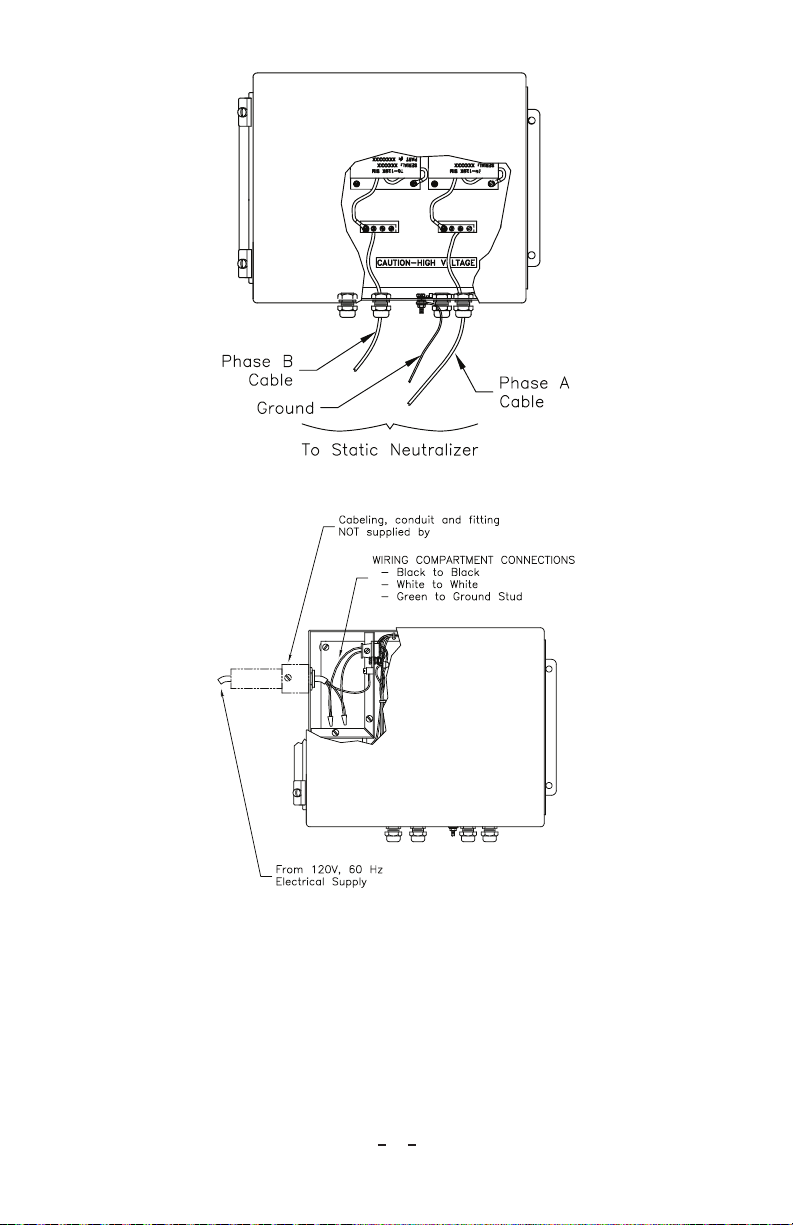

AC Line Power (Low Voltage) Connections

CAUTION

–

Do not apply line voltage to the Power Unit until all grounds

and high voltage connections have been completed and the static neutralizer

has been installed.

1. Connection should be made only to a 3-wire 120V, 60 Hz AC source.

2. For rigid cable connection to the power unit: the use of local code approved

solid 3-conductor cable through ½” size conduit with approved fittings is

recommended (not supplied). On installations subject to Canadian Standards

Approval: the use of conduit is required.

3. For flexible connection to power unit: the use of local code approved

3-conductor line cord is recommended (not supplied). Secure line cord to

power unit with an approved cable clamp.

4. Connect the power source to the black and white leads using proper size wire

nuts. Connect the grounded conductor to the ground post.

NOTE

–

If the static neutralizer is to be used on machinery, it is recommended

that the power unit’s input wiring be connected to the machine’s RUN

button. This will enable the power unit to be turned ON and OFF with the

machine.

Warning / Fault Conditions

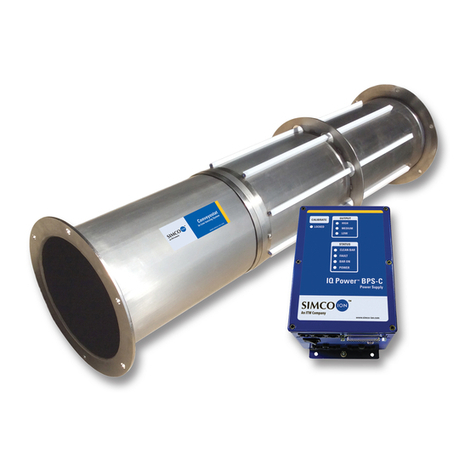

The Dual Phase+ generates warning and fault conditions based on the operational

conditions of connected hardware. Warning conditions indicate that material

(typically metalized film) is congesting the connected Conveyostat and impeding

the output of one or more ionizer bars. The Warning condition is indicated by a

yellow light. It is normal that the warning condition may be intermittent. Even

with the Warning indicated, the Dual Phase+ continues to produce ionization in

the Conveyostat system. If the Warning is indicated continuously, service should be

scheduled to remove material trapped in the Conveyostat.