2

Chargemaster Pinner Superbar 5101167 Rev. F

2. DESCRIPTION

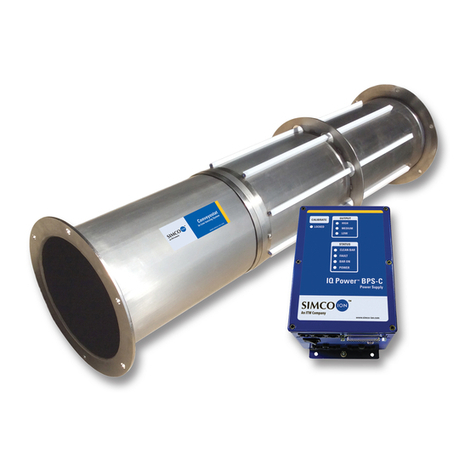

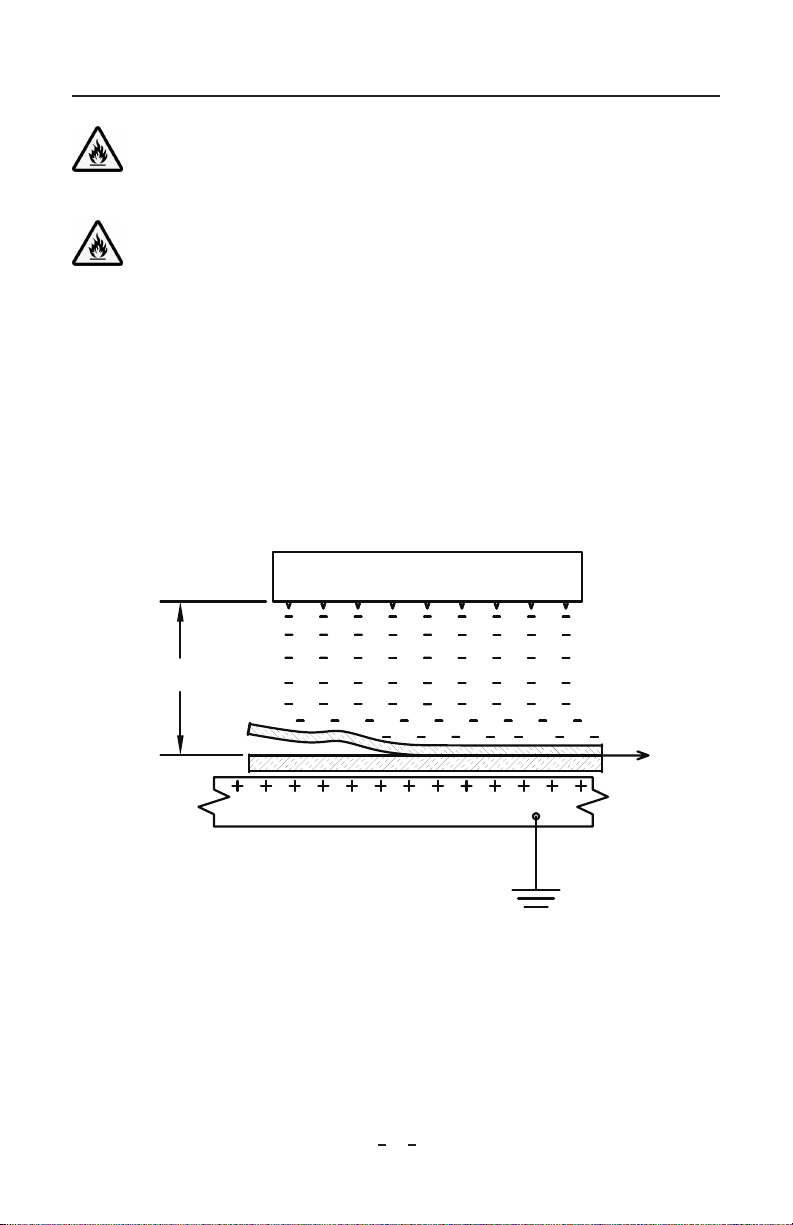

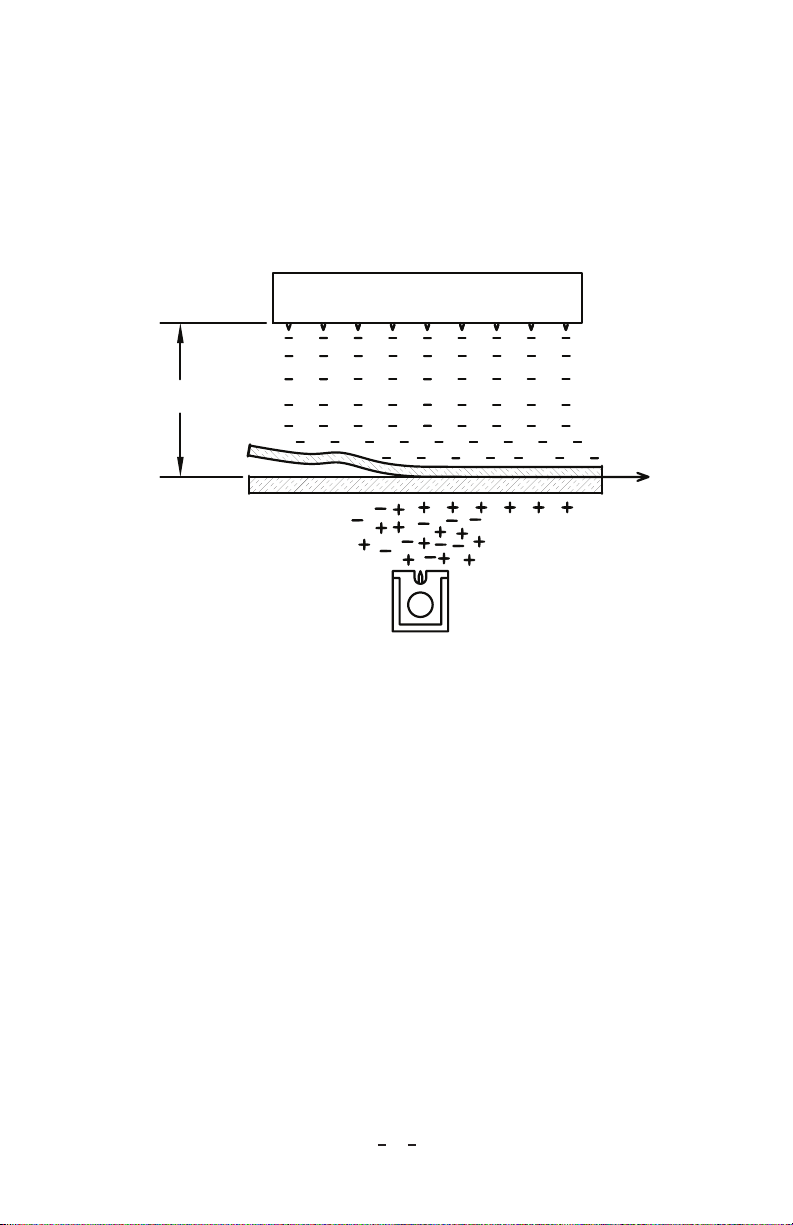

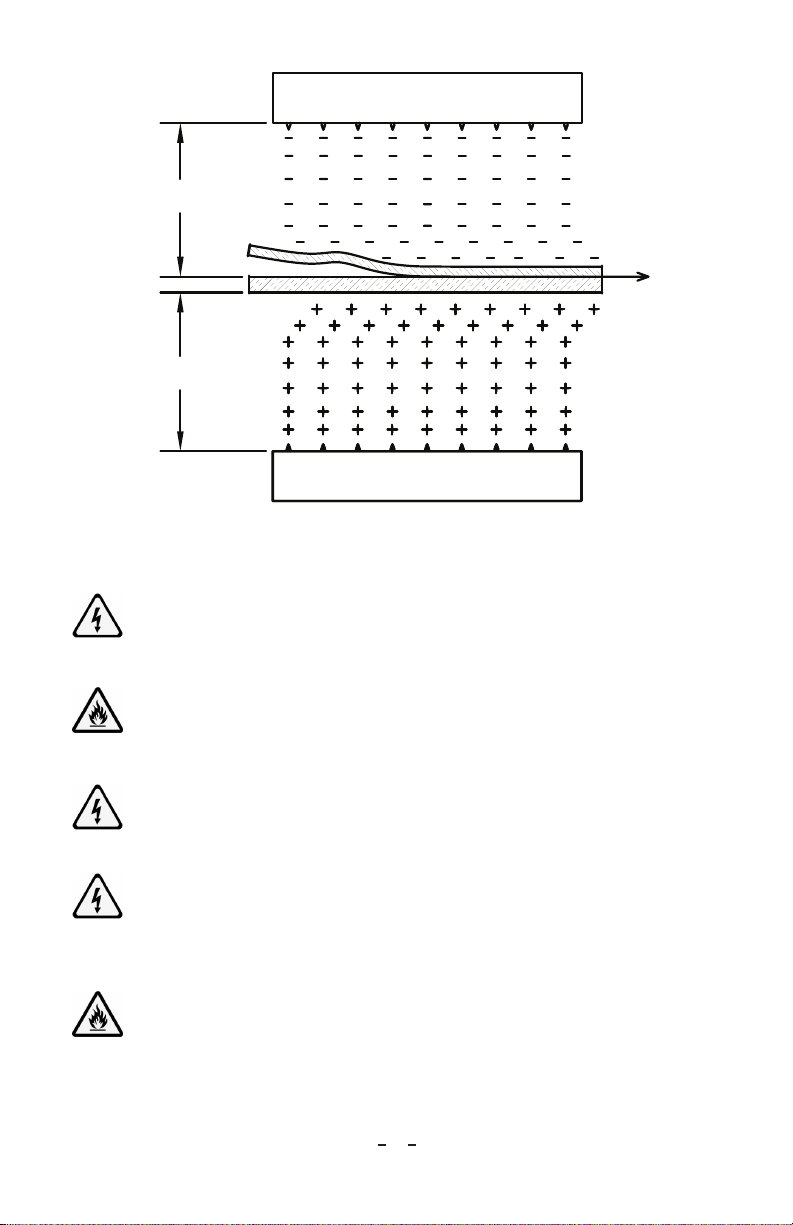

Simco-Ion’s Pinner Superbar Charging Applicators are part of the Chargemaster

Electrostatic Generating System. The Superbars are energized with Simco-Ion

Chargemaster CH or BP series DC power supplies that provide the necessary high voltage

(up to 30 kV) for operation. This system is used to produce electrostatic adhesion for

temporarily bonding or pinning materials. The success of the process depends on the

insulating qualities of the material being charged, the distance to ground, distance between

bars, cleanliness, ion pin sharpness and the applied voltage. Good insulators, such as

plastic films, work particularly well with this process.

Eight rows of ionizing pins enable the Superbar to produce more ionization and afford

higher pinning action than conventional charging bars. The locations of the ionizing pins

on the charging bar are divided into two sections. Each row consists of four sets of pins.

Pin alignment for both sections is staggered to increase the effective pinning area.

Pinner Superbars are resistor-limited to provide arc-resistant operation. It is this

advancement that prevents hard arcs from occurring resulting in several improvements

when compared to traditional charging equipment:

• Increasedvoltageconsistencyandcontinuouspinningaction

• ReducedEMI/RMIthatcandisturbsensitiveelectroniccomponents

• Limitedenergyreleasethatcouldotherwisedegradesomeplasticsandother

materials causing additional damage and failures

CAUTION – Personal Injury Hazard. Pins are very sharp, be careful when

handling Superbars.

Receipt of equipment:

1. Carefully remove the equipment from its carton.

2. Inspect contents for damage that may have occurred during shipment. If any

damage has occurred, the local carrier should be notified at once. A report should be

forwarded to Simco-Ion, 2257 North Penn Road, Hatfield PA 19440, and (215) 822-

6401.

3. Empty the carton to ensure that small parts are not discarded.

Return Shipments:

Prior to returning goods, contact a Simco-Ion Customer Service Representative for a

Return Authorization Number. This number should be included on the packing list. All

correspondence should also reference the Return Authorization Number. Any item being

returned should be shipped prepaid and packed to provide adequate protection.