2

R50 Blue Bar 5101171 Rev. L

2. INTRODUCTION

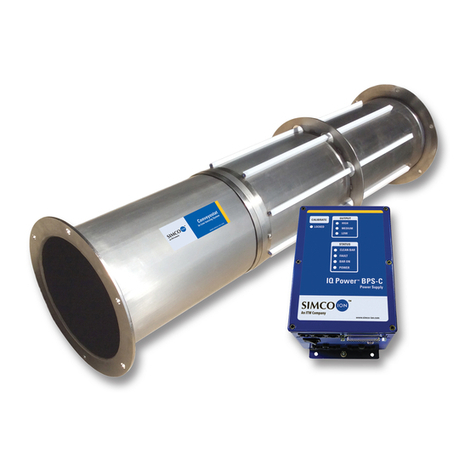

Simco-Ion’s N167, N257, N267, D167Q, D257Q, and TrueAC power supplies are

designed as a power source for the static neutralizing R50 Blue Bar. The R50 Blue Bar

is used to eliminate or significantly reduce static charges that disrupt manufacturing

processes. The high voltage from the power supply causes the ionizing pins of the static

neutralizing bar to generate both positive and negative ions from the surrounding air

molecules. The static charge on the material being processed will attract and combine

with the oppositely charged ions, causing the material to be neutralized. The excess ions

either recombine in air or dissipate to ground.

R50 Blue Bar

The R50 Blue Bar is current limited shockless bars with resistors in series between each

emitter pin and the high voltage source. The Blue Bars incorporate an encapsulated

internal ground reference. The current-limited design provides an added safety feature to

prevent hazardous electrical shocks if there is contact with the ionizing pins. This safety

feature does not compromise the static bar’s performance.

Features

• Current limited to prevent electrical shock from contact with ionizing pins.

• Built-in ground reference inside bar for maximizing ion generation.

• Flexible shield high voltage cable to limit EMI and RFI.

• Continuous mounting slot to allow installation flexibility.

“N” Power Supplies

The Simco-Ion Type N Power Supply provides multiple high voltage outputs for

powering various types of static eliminating equipment. Although there are various

models, they are basically the same with respect to mounting, connection, and operation.

Each power supply operates on a specific line voltage and frequency and provides a

specific high voltage output. The voltage of the power supply needed depends upon the

type of static eliminating device it is to power. Therefore, the power supply must be used

only with the device for which it was originally supplied. Do not add any device to the

power supply without first consulting Simco-Ion.

If it should become necessary to contact Simco-Ion regarding the power supply, please be

sure to reference the power supply model number and unit number. These numbers are

listed on the label affixed to the power supply. Line voltage and frequency requirements

as well as output ratings are listed on the nameplate.

The Simco-Ion Type N Power Supplies are UL and CSA listed. These power supplies

also carry CE approval.