1

IQPower™HL 5201201Rev.D

1. SAFETY WARNINGS

Simco-Ion recommends that these instructions be read completely before installation or

operation is attempted. Failure to do so could result in personal injury and/or damage to

the equipment.

NOTE – Statements identified with NOTE indicate precautions necessary to avoid

potential equipment failure.

CAUTION – Statements identified with CAUTION indicate potential safety

hazards.

NOTE – This equipment must be correctly installed and properly maintained.

Adhere to the following notes for safe installation and operation:

1. Read instruction manual before installing or operating equipment.

2. Only qualified service personnel are to perform installation and repairs.

3. All equipment must be properly grounded, including the machine frame to which the

equipment is mounted.

4. Disconnect input power to power supply before connecting or disconnecting static

neutralizing bars to the high voltage power supply.

5. Do not operate the power supply in close proximity to flammable liquids.

6. Do not use standard Ethernet cables with IQ Power

TM

Systems.

CAUTION – This product is intended to be supplied by a Listed AC Adapter

or Power Unit marked “Class 2” or “LPS” and rated output 24V

DC, 3.75A.

CAUTION – Electrical Shock Hazard

Disconnect input power to the power supply before connecting or

disconnecting static neutralizing bar or performing any maintenance to

the system. Avoid touching static neutralizing bar when power supply

is energized.

CAUTION – Fire Hazard

Do not install or operate the power supply in close proximity to any

flammable liquids or solvents.

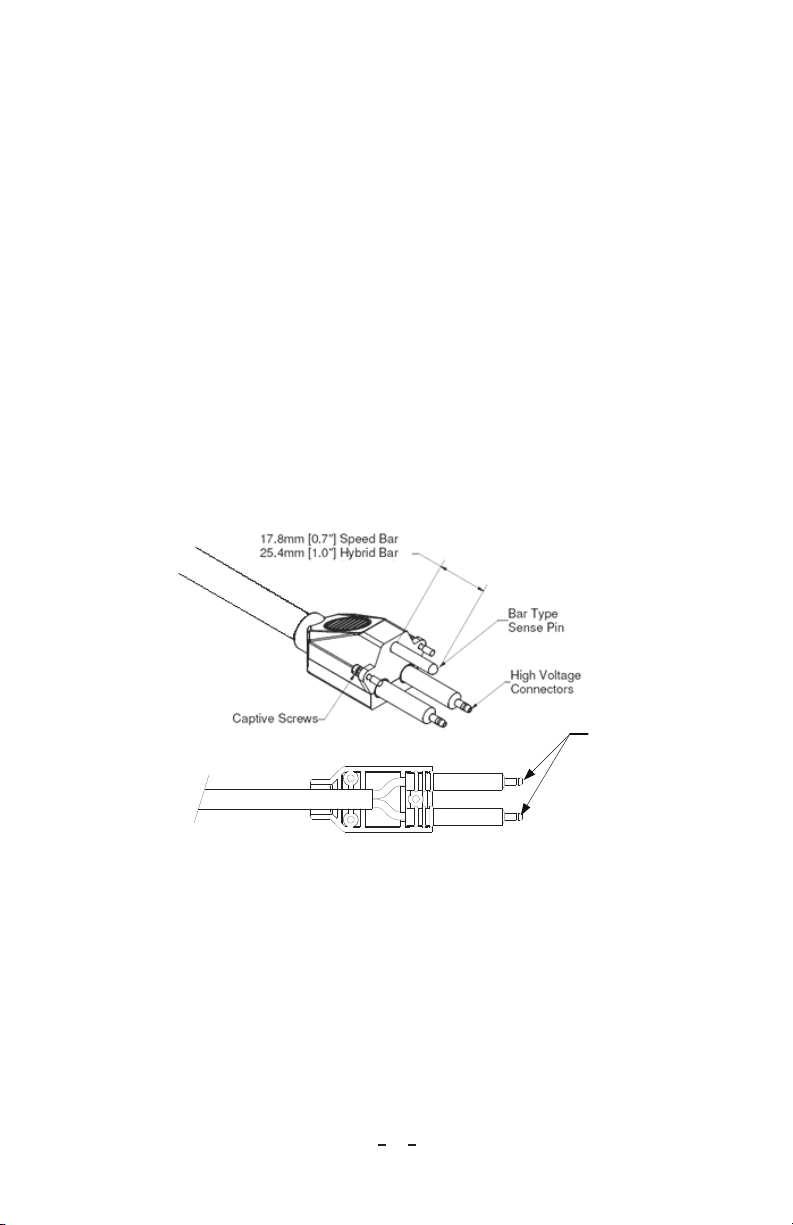

WARNING – Substitution of components may impair intrinsic safety. (refer

to Figure 1)

AVERTISSEMENT – La substitution de composants peut compromettre la

securite intrinseque. (referez-vous au schema 1)