HOSE CLAMPS FROM MAZDA ARE BEST

REMOVED BY APPROACHING FROM THE

SIDE WITH NEEDLE NOSE PLIERS. GRASP

ALL THREE TANGS AT ONCE AND COMPRESS

THEM TOGETHER. THIS IS EASIER TO DO

WITH THE THROTTLE BODY ALREADY LOOSE

FROM THE INTAKE MANIFOLD. Plug the

coolant hoses with a screwdriver, golf tee, or pen-

cil to prevent the leakage of coolant (OR - keep

the hose ends above the radiator cap level to pre-

vent leakage). Release the throttle cable from the

throttle shaft spool. Release the Throttle Position

Switch harness by lifting the small wire clip that

runs around the rectangular base of the connec-

tor. If the throttle body gasket tears as you

remove it (even though it is made of metal, it can

tear), you will need to clean off the old gasket

from both surfaces, the throttle body and the

intake manifold. Carefully use a knife or the back-

side of a hacksaw blade to scrape the mounting

surfaces clean. DO NOT SCRATCH OR MAR

THE MOUNTING SURFACES IN ANY WAY.

Immediately below and behind the throttle body

on the intake manifold is a steel support brace in

the shape of an inverted “L” attached by four

12mm headed dolts. Remove the brace and re-

secure the wiring harness ground wire attached

at that point with one of the 12mm headed bolts.

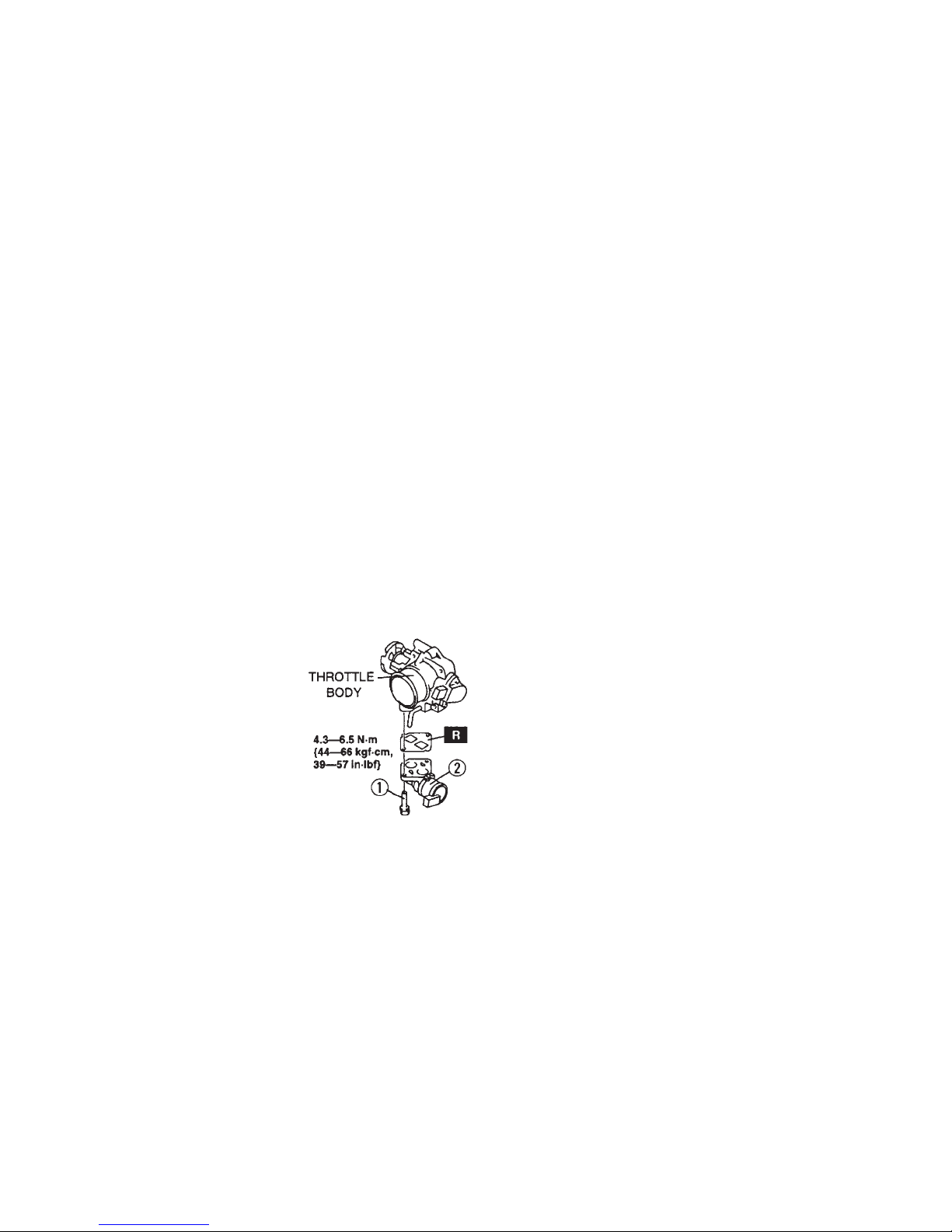

2.2 Moving to a worktable, remove the idle air

control (ICS) valve from the bottom of the throttle

body by removing the two

Phillips head screws. Use a

good quality screwdriver and

be careful not to strip the

Phillips head screw. If you

cannot loosen a screw with

the screwdriver, use a small

set of pliers from the side.

Carefully separate the two

units making sure not to tear

the gasket. The gasket will want to stay with the

Mazda ICS valve.

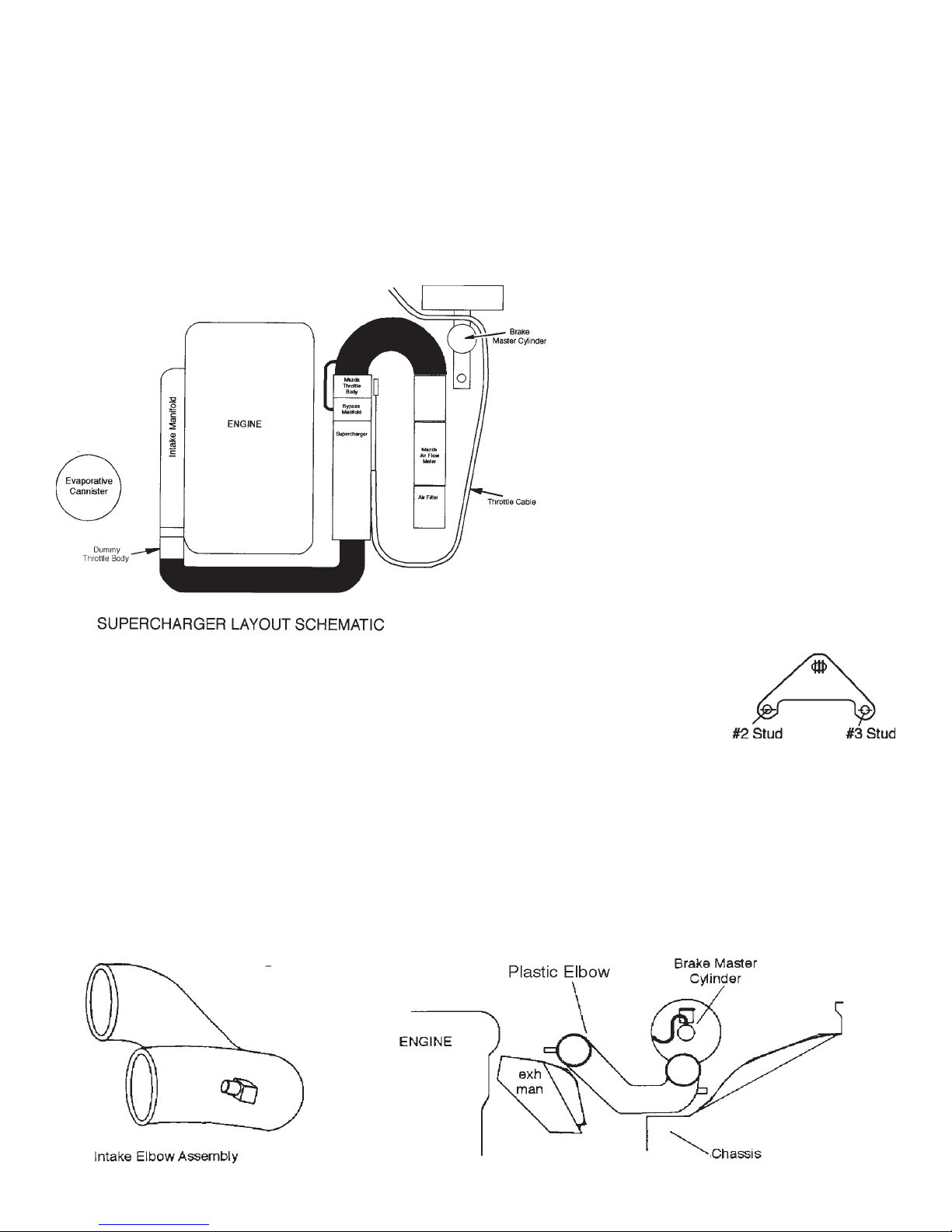

2.3 Take the Dummy Throttle body from your

supercharger kit and install the Mazda Idle Air

Control Valve (ICS) from step 2.2 on the bottom,

rotating the ICS valve 180 degrees so that the

electrical connector now points to the rear of the

engine. Use the Mazda original ICS to Throttle

body gasket.

2.4 Install the Dummy Throttle Body and ICS

valve assembly back onto the intake manifold in

the same position as the standard Mazda throttle

body. Use the original gasket or the1104 adhesive

on the mating surfaces and the two new 8mm x

40mm long bolts provided in the lower two holes

on the dummy throttle body. Reconnect the

coolant hoses to the brass coolant barbs on the

front and side of the dummy throttle body.

2.5 Do not connect the ICS electrical connection

until after the next step.

2.6 Wiring Harness Modifications:

Locate the main engine wiring harness on the left

side of the engine (as viewed from the front of the

engine) where it runs between the intake manifold

and cam cover. Cut the strap of the white plastic

harness anchor at the front and release the fire-

wall end of the harness by gently prying the

release tab on the securing clamp located near

the rear engine lifting eye. Starting at the forward

point where the four black/yellow wires come out

of the harness, cut the black tape binding the

plastic corrugated tubing so that you can access

the wires within. Locate the wiring branch of the

ICS valve connector and follow the wires to the

main harness. Pull these two wires (purple and

orange) back free from the main harness about 4-

5 inches so that you have enough slack to plug

the connector in the repositioned ICS valve. Cut a

length of the small diameter corrugated tubing

supplied in the kit to cover the wires on the ICS

branch from the plug to the main harness with an

additional inch of tubing to protrude into the main

harness tubing. Locate the wiring harness branch

for the Throttle Position Switch (TPS) that origi-

nally connected at the throttle body connector.

Pull these wires back to about 4 inches from the

firewall. If the construction of your particular har-

ness is such that you cannot free all three wires

(light green/red, green/black and black/pink) all

the way back, cut the offending wire (usually light

green/red) and pull the wires with the connector

back free. Then strip about 1/4 inch of insulation

of each end of the cut wire and using the Crimp

connector supplied; insert a stripped end into

each end of the connector. Crimp (collapse) each

end of the connector onto stripped ends, making

sure that the connection is secure. With the crimp

connector installed on the wire, shrink seal the

ends of the Crimp connector by heating it with a

heat gun or a hair blow dryer. Using some of the

small diameter corrugated tubing provided, cover

the TPS harness branch. Wrap the main harness

and branches with the roll of tape supplied in the

kit, in the same manner as the factory had.

Reattach the harness at the rear harness clamp

by snapping it back in place and at the front by

using a new Ty-Wrap strap through the base of

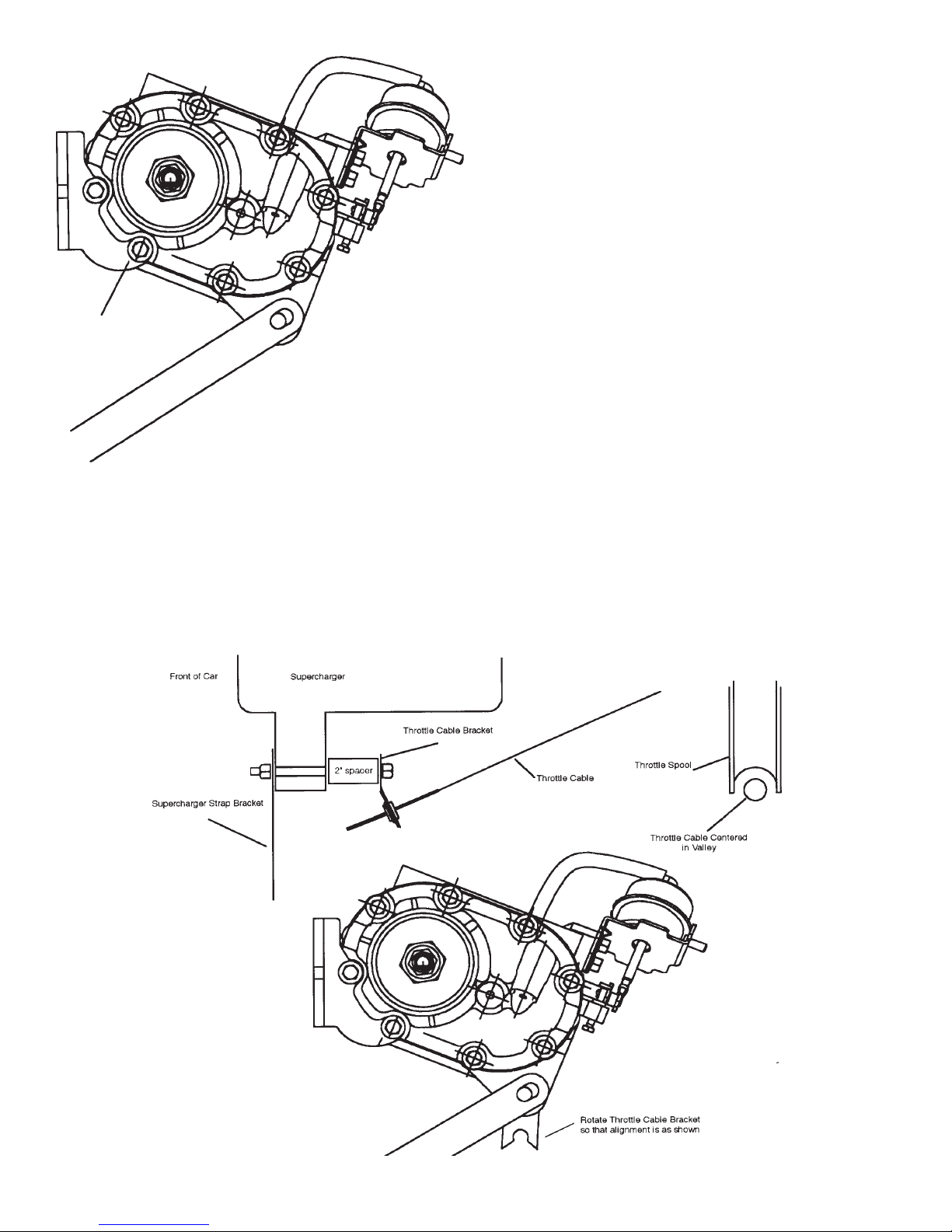

the white plastic anchor. You can now plug in the

ICS valve connector by routing the harness

branch under and around the intake manifold to

the ICS valve. The TPS connector will be plugged

in after installation of the supercharger and throt-

tle body assembly.

31/07999-200