OR CONSEQUENTIAL DAMAGES. Some US states or Canadian provinces do not allow the

exclusion or limitation of incidental or consequential damages, so the above may not apply to you.

This warranty applies to products used in swimming pool, spa, & aquaculture applications only and does

not apply to any product which has been subjected to negligence, alteration, accident, abuse, misuse,

improper installation, abrasives, corrosion and/or electrolysis, improper voltage supply, vandalism, civil

disturbances, or acts of God (including but not limited to freeze damage, lightening strikes, and other

damage caused by catastrophic events). The only warranties authorized by CPP are those set forth herein.

CPP does not authorize other persons to extend any warranties with respect to its products, nor will CPP

assume liability for any unauthorized warranties made in connection with the sale of its products. The

Company will not be responsible for any statements that are made or published, written or oral, which are

misleading or inconsistent with the facts as published in the literature or specifications furnished by the

Company.

WARRANTY CLAIM PROCEDURE

Warranty claims shall be made by contacting the installing/selling, builder, dealer, or retailer (point of

purchase) or the Jacuzzi pool products distributor in your area. All equipment must be inspected by a local

Company representative or at the factory before warranty is authorized. All charges or expenses for freight

to and from the factory, removal and reinstallation of the products, or installation of a replacement product

are the responsibility of the purchaser unless otherwise expressly authorized by Cantar Pool Products.The

Company, at its discretion, may repair or replace free of charge (F.O.B. factory in Toronto, Ontario) any

product that proves defective within the warranty period, or it may issue credit in the amount of the invoice

of the defective equipment in lieu of repair or replacement. The Company reserves the right to substitute

new or improved equipment on any replacements. The provisions of this additional written warranty are

in addition to and not a modification of or subtraction from the statutory warranties and other rights and

remedies provided by any US state or Canadian provincial law.

JACUZZI POOL PRODUCTS - Limited Warranty

Cantar Pool Products (the Company or CPP) warrants Jacuzzi pool products to be free of defects in

material and workmanship for a period of 36 months from the date of purchase or 48 months from the date

of manufacture, whichever comes first, with the following exceptions:

Shaft Seals - For all pumps with Jacuzzi’s patented “dry-run” heat sink, the shaft seal carries an

unconditional warranty against damage or failure for 2 years from date of purchase/installation.

Light Bulbs - FullMoon Watercolor LED light bulbs are warranted for 1 year from date of purchase;

incandescent bulbs are warranted for 90 days from date of purchase.

Misc. - Filter elements, DE grids, white-goods, strainer baskets, strainer basket “flap” and “priming tube”,

pressure gauges, square rings, o-rings, gaskets, and all replacement parts are warranted for 1 year from

the date of purchase.

In order to activate this 3-year warranty, Jacuzzi products may be registered with Cantar Pool

Products by either of the following methods:

•Mail-in Warranty Registration Card •Online at www.cantar.com

This warranty extends only to the original retail purchaser and only during the time in which the original retail

purchaser occupies the site where the product was originally installed. CPP’s warranty obligation with

regard to equipment not of its own manufacture is limited to the warranty actually extended to CPP by its

suppliers.

THIS WARRANTY IS EFFECTIVE January 1, 2005. ANY IMPLIED WARRANTIES WHICH THE

PURCHASER MAY HAVE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, SHALL NOT EXTEND BEYOND THE APPLICABLE WARRANTY PERIOD. Some US

states or Canadian provinces do not allow limitations on how long an implied warranty lasts, so

the above limitation may not apply to you. IN NO EVENT SHALL CPP BE LIABLE FOR INCIDENTAL

Manufacturer’s Warranty:

4

WARNING

!Disconnect power to motor main circuit

breaker to avoid electrical shock. If filter Ring-

Lok is removed or adjusted under pressure, the filter cover may blow off, caus-

ing injury or major property damage.

EXCESSIVE NOISE COMING FROM PUMP OR MOTOR.

The basket in the skimmer or the lint strainer may be clogged; The motor bearing may be worn out;

Valve in suction line may be partly closed; Suction line may be partly plugged; The vacuum hose may

be plugged or too small; The pump may not be supported properly.

WATER LEAKS FROM SHAFT.

Shaft seal requires replacement.

FILTER TANK LEAKS WATER.

Split in tank due to freeze or other damage. Replace; Lid O-ring damaged, twisted, or not lubricated.

Inspect; Lock ring to lid not tight. Inspect and tighten down to engage lock tabs; Air bleed valve loose or

O-ring missing. Inspect; Inlet/outlet fittings loose or not sealed. Inspect.

DEBRIS BACK TO POOL.

Dirty filter. Clean element in filter cleaner or replace; Cracked dirt catcher. Inspect and replace if neces-

sary; Filter collapsing. By-pass through top of dirt catcher. Inspect or replace; Holes in filter. Replace;

Filter isn’t sealed in dirt catcher. Inspect; Filter is installed upside down. Install top-side up. Inspect.

FILTER DOESN’T KEEP WATER CLEAN.

Fitler collapsing. By-pass through top of dirt catcher. Inspect or replace; Holes in filter. Inspect or replace;

Filter installed upside down. Inspect or install top-side up; Filter isn’t seated in dirt catcher. Inspect;

Water started out dirty. Continue to filter and clean as necessary; Heavy swimmer load. Clean filter as

necessary; Flow rate too low. Increase flow to turn water more often.

PRESSURE DOESN’T DROP IN FILTER AFTER CLEANING.

Dirty filter. Clean element in filter cleaner or replace; Gate valve closed in return line. Inspect; Return line

partially clogged. Inspect; Return fitting clogged. Inspect.

TANK WILL NOT ALIGN WITH BASE MOUNTING HOSES.

Check position of tank; Rotate; Loosen pump from base to allow filter to move and align.

FILTER LID LEAKING.

Inspect O-ring, cracks, twisted. Replace; Lid cracked. Replace; Tank cracked. Replace.

SERVICE & REPAIR PARTS

Refer all sevice to your local dealer. Order all repair parts through your dealer. Give the following informa-

tion when ordering repair parts: Unit nameplate information and description of part. If the recommenda-

tions in the “Trouble Shooting” portion of this manual do not solve your particular problem please contact

your local dealer for service.

THE MOTOR DOES NOT START WHEN YOU PLUG IT IN.

The disconnect switch or the circut breaker is in the OFF position; Fuses may be blown or the thermal

overload is open; Motor shaft is locked; Motor windings are burned out; A defective starting switch

inside the single-phase motor; Wiring may be disconnected or defective; Low voltage in outlet.

THE MOTOR DOES NOT REACH ITS FULL SPEED.

Low voltage; Two-speed model set on low speed; Motor windings connected for wrong voltage on dual

voltage model.

THE MOTOR OVERHEATS AND THE PROTECTOR TRIPS.

Low voltage; Inadequate ventilation; Motor windings connected for wrong voltage on dual voltage model.

NO WATER IS DELIVERED BY PUMP.

Pump is not primed; Closed valve in suction or discharge line; Leakage of air into the suction system;

Impeller clogged.

AIR BUBBLES APPEAR AT INLET FITTINGS.

Air may be leaking into the suction line at the connections or valve stem; Cover gasket or lint strainer

may need cleaning; Restriction in suction line or low water level in pool.

LOW CAPACITY WHEN PUMP IS TURNED ON.

Valve in suction or discharge line is partly closed; Suction or discharge line is partly plugged; Suction or

discharge line is too small; The basket in the skimmer or the lint strainer may be clogged; The filter may

be dirty or the impeller may be clogged.

LOW PRESSURE WHEN PUMP IS TURNED ON.

The discharge valve or inlet fittings may be open too wide.

HIGH PRESSURE WHEN PUMP IS TURNED ON.

The discharge valve or inlet fittings may be closed too much.

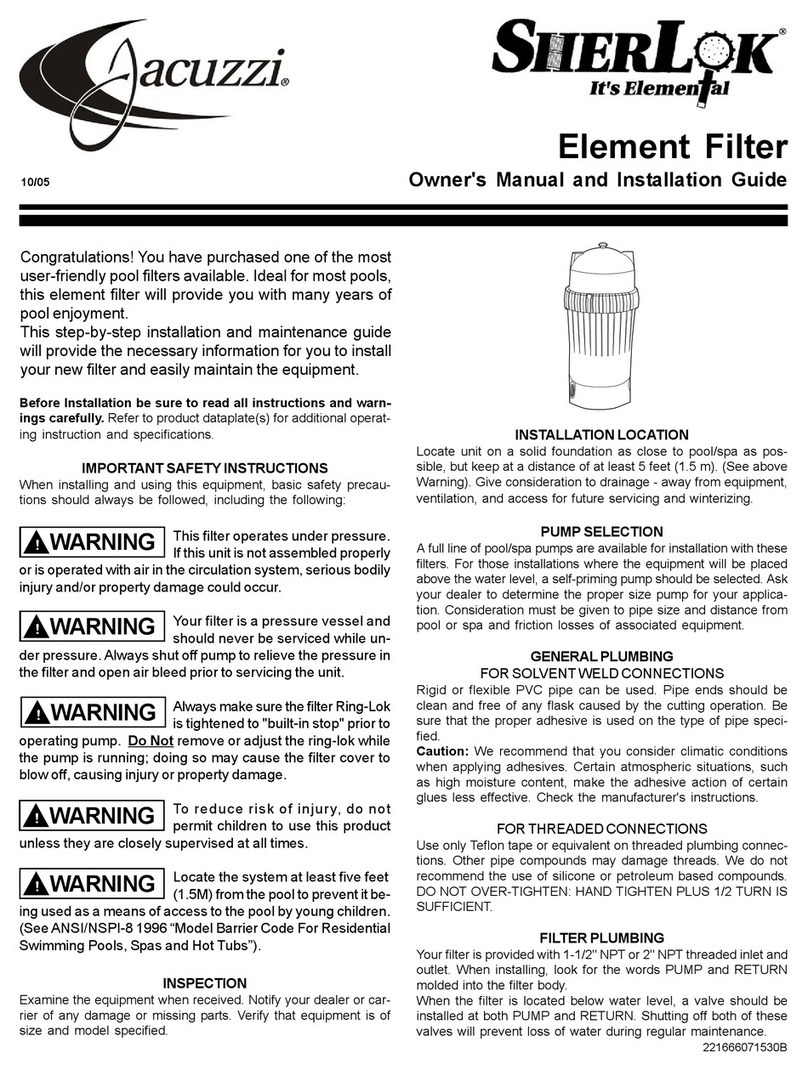

Step 3

Drain pump strainer and pump case by loosening the

plugs shown. The pump will drain without completely

removing the plugs from the pump. NOTE: If tempera-

tures in the winter are severe, you may choose to dis-

connect your filter system from the pool and move it to

a protected area.

Drain

plugs

Winterizing the filter system and water maintenance:

To avoid electrical shock, unplug the pump before performing any service or maintenance. If filter Ring-Lok is removed

or adjusted under pressure, the filter cover may blow off, causing injury or major property damage.

WARNING

!

Water maintenance:

A proper and consistent use of chemicals is necessary

to maintain clean, sanitary water, to prevent a spread

of germ infection and control the growth of algae which

can spoil the appearance and enjoyment of your pool

or spa. See your pool professional for proper chemical

maintenance.

Trouble Shooting:

Unplug the pump cord.

Step 2

Drain the filter tank by first removing the

drain cap and then opening the air bleed

valve. Replace the drain cap once filter is

drained.

Step 1

For above-ground pools with the filter system located below the pool

water level: You must drain the water in the pool below the skimmer

and inlet fitting. Follow pool manufacturer’s recommendations for

winterizing the pool. Your system is full of water.

STOP

Open air bleed

valve second

Remove drain

cap first

In Canada 325 Humber College Blvd. Toronto, ON, M9W 7C3 Phone: 800.836.1210 Fax: 416.798.2801

In USA 1515 S. Bowman Rd., Suite A Little Rock, AR 72211 Phone: 866.370.2664 Fax: 800.447.3181

CANTARCANTAR

CANTARCANTAR

CANTAR Pool Products Ltd.Pool Products Ltd.

Pool Products Ltd.Pool Products Ltd.

Pool Products Ltd.

Produits de Piscine Ltée.Produits de Piscine Ltée.

Produits de Piscine Ltée.Produits de Piscine Ltée.

Produits de Piscine Ltée.

Jacuzzi is a registered trademark of Jacuzzi Inc. and used under license.

R