a Perch Bar option. If this cannot be achieved in the crosswise direction, consider a different

layout or using packing pieces to ensure the specification can be met.

During assembly:

If necessary drill holes into the base of the JLX-LITE-MkII as required.

Use 20mm (minimum diameter) mud washers under the head of each fixing.

If using Nylocks ensure the thread is fully engaged in the nylon. If Nylocks are not used, use

lock washers under each nut.

Wall plugs should not be used.

The mains outlets are available on one side of the base only. It is recommended the mains out-

let side of the bar face away from the audience view if possible.

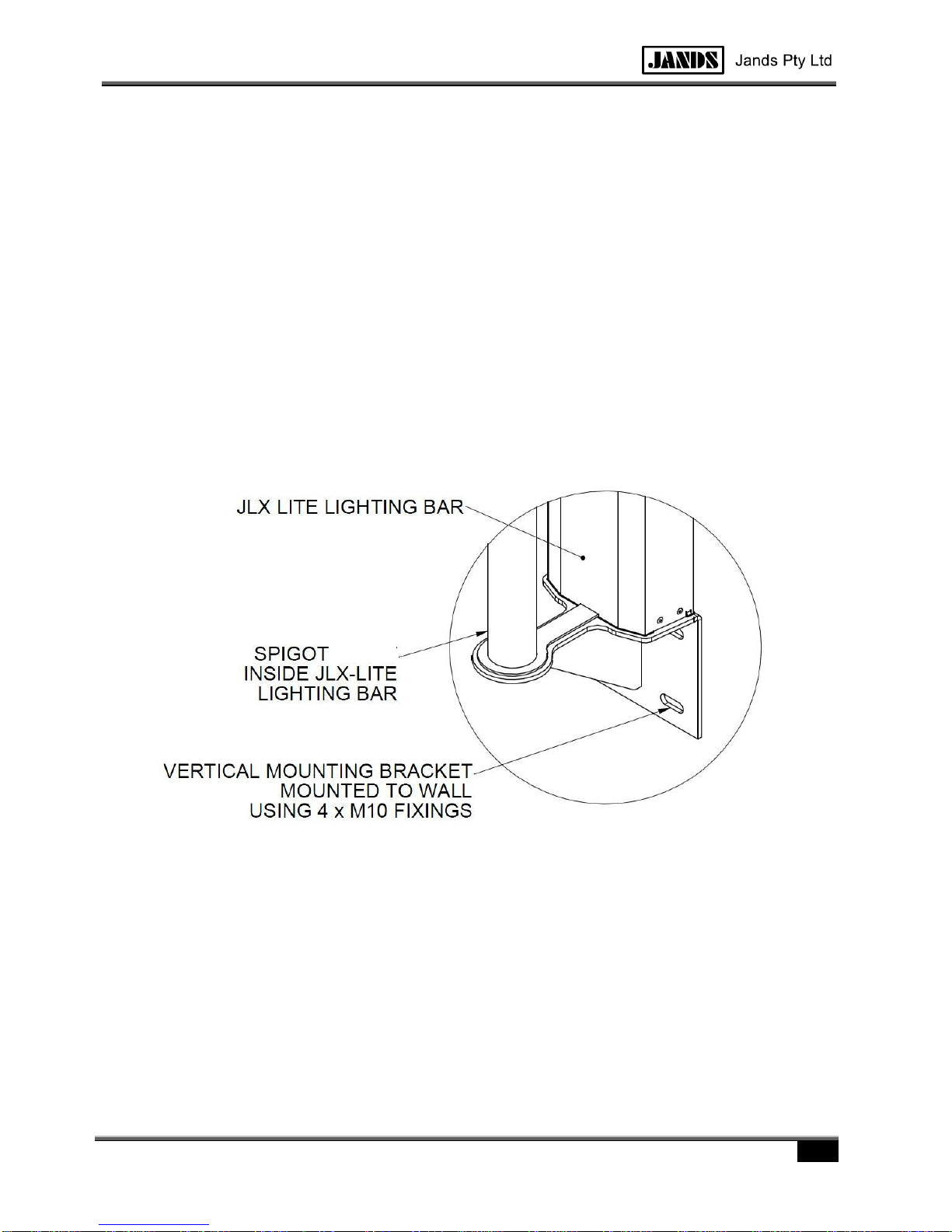

Two or more JLX-LITE-MkIIs may be mounted end to end to create one longer bar. A single joining

spigot is supplied with each JLX-LITE-MkII to end-align these bars. The spigot is not intended to carry

any significant load and should not be used in lieu of fixings in the base.

2.3 Planning - Electrical

The JLX-LITE-MkII is supplied with unwired/loose mains sockets that can be configured during installa-

tion. Some options include:

One circuit for all outlets. This is more suited to small installations or where no dimming is re-

quired - the outlets are used to power non-dim equipment such as LED fixtures and moving

lights.

Each supply circuit feeding a small number of outlets - for example one circuit feeding two out-

lets. Circuits may run direct to a switchboard or to a patch panel if dimming may be required.

This is suited to intermediate installations.

Individual circuits wired to a patch panel. This is the most flexible arrangement allows circuits to

be used as dimmers or direct power at will.

The mains outlets are available on one side of the base only. It is recommended the mains outlet side of

the bar face away from the audience view.

The JLX-LITE-MkII includes a number of knockouts and holes in the mounting face and ends of the

base. If the wiring can be planned before mounting it will be easier to remove the required knockouts

while the JLX-LITE-MkIIs are on the floor, prior to mounting. If the wiring hasn't been planned or there is

doubt about the how it will be done, they should be left in place for removal by the Electrician during in-

stallation.

2.4 Installation

The following is the installation procedure for horizontal bars. If mounting the JLX-LITE-MkII at an angle

greater than about 6 degrees lengthwise, use the Perch Bar option. Refer to section 2.5. It is intended

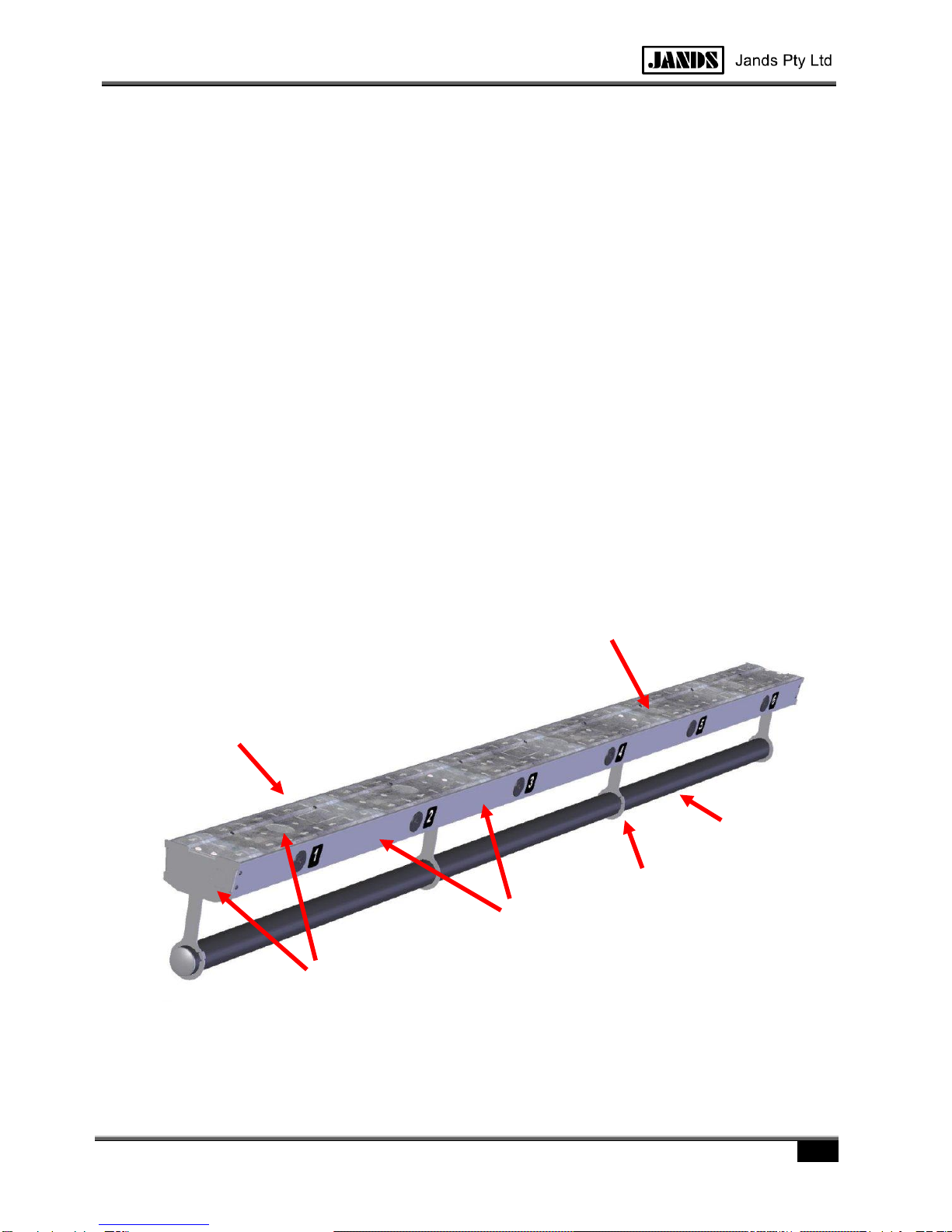

that the JLX-LITE-MkII be installed with the bar in place.

1. Install the supporting structure. See the available options and notes in section 2.2.

2. Remove the dress covers by removing the screw and sliding the cover along the bar enough so

it can be angled out of the available gap between the bar supports. Put the covers and screws

to the side with the other supplied accessories