Introduction 1-0

Revision 2 - 20 March, 1997 HP SERIES DIMMER OPERATING MANUAL

1.0 Introduction

The JANDS HP12 series dimmers are rugged, high quality, 12 channel, 2.5kVA per

channel dimmers specifically designed for demanding touring and theatre

applications.

The HP12-TR features opto-controlled Triacs and medium risetime chokes; the HP12-

SC features DC-fired SCR pairs and high risetime chokes.

Complementing the HP12-TR / HP12-SC are the HP12-WMTR (wall-mounted Triac

dimmer) and the HP12-WMSC (wall-mounted SCR dimmer).

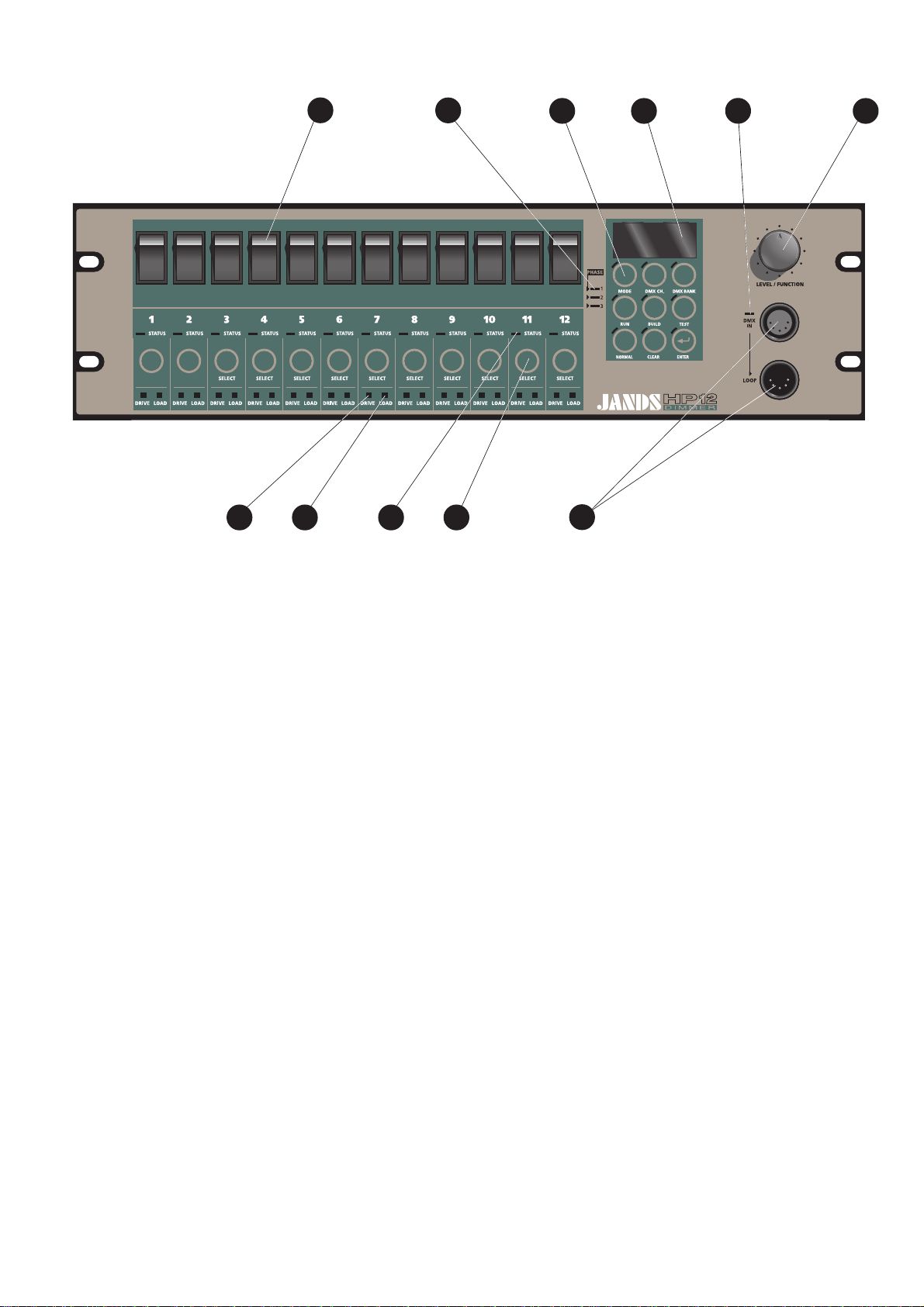

The HP12 series of dimmers feature microprocessor-based digital control. A keypad,

rotary encoder, channel switches, LED indicators and a large alphanumeric display

enable the user to monitor and select the built-in functions.

The user has the ability to select the DMX start number either by channel number or

in banks of 12 channels, test selected channels while the remainder of the dimmer

stays “on line”, select output voltage (eg. 120V) or ramp curves for designated

channels, capture up to three non-volatile DMX “snapshots”, build two user-definable

non-volatile scenes with the ability to import/select/set individual channel levels, and

to select from six “factory” built-in scenes including chases/random/crossfades. Other

functions also provided include dimmer “soft” start, channel-by-channel preheat

function, the ability to monitor the status of the dimmer rack in relation to supply

voltage, a bad (soft) neutral connection, over-temperature and other working

parameters of the unit.

The dimmer will “wake-up” in the mode it was last programmed to run - an ideal

function for stand alone applications. If no particular mode has been previously

defined, the dimmer rack looks for DMX control. If the rack loses DMX control at

any time while running, it defaults to the last received DMX command.

HP dimmers feature JANDS’ Ferrodipchokes. These chokes provide high rise time

along with excellent high frequency noise suppression and low acoustic noise.

The HP range of dimmers has been designed to allow for future optional upgrades to

the operating system.

Control signal to rack-mount dimmers is via a standard DMX-512 socket at either the

front panel or rear panel, while the dimmed outlets and three phase power entry are

located on the rear panel.

Control signal and three phase power entry to wall-mount dimmers are on internal

screw terminal blocks, while the dimmed outlets are on either internal screw terminal

blocks or front outlets (GPO's).

Bracket systems for the wall-mounted dimmers allow a wide variety of mounting

options - flush to the wall with rear wire entry, straddling cable trays, conduited

wiring from all four sides or mounted in standard rack frames and strips.