Prophi®6T

7

2.3 Alarm output / error messages

The alarm contact is closed in normal operation and opens in the event of a fault. The

relevant fault is simultaneously shown on the display in plain text (alternating with the

standard display in automatic operation). The following fault messages are displayed:

UNDER-COMPENSATED Display and relay output

missing reactive power

OVER-COMPENSATED Display and relay output

OVERCURRENT Display and relay output

MEASURING VOLTAGE ? Display and relay output

OVERTEMPERATURE Display and relay output

OVERVOLTAGE Display and relay output

UNDERVOLTAGE Display and relay output

HARMONICS Display and relay output

Section 3 Operating modes

When the operating voltage is switched on, the device displays its designation and

software version, then changes to its normal operating status (automatic operation). The

active cos-phi value is always displayed in the upper line and the currently connected

capacitors are shown as symbols in the lower line (operating display).

Additionally several messages for different operation states are generated. An individual

adjustment resp. suppression of particular messages is possible in expert mode 2. During

suppression, the indication of the message in the display, a possible release via alarm-

relays and effects on the controlling process will be prevented.

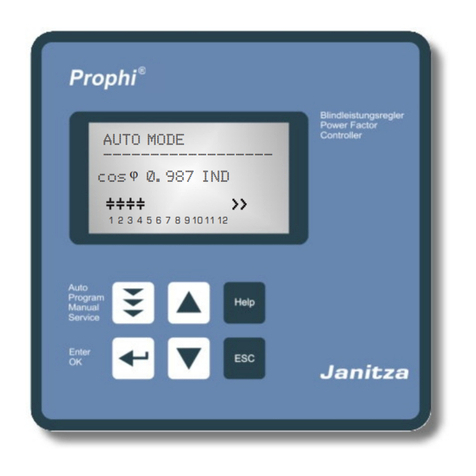

Automatic operation

Display of active power-line cos phi

Active capacitor

branches

Control direction

(here connected-in)

Supply display (for

4-quadrant operation)

The control direction is symbolized

by a closed arrow

The connecting-in arrow is always

located after the maximum possible

number of stages (end stop)

An open arrow indicates that the

required blocking time (discharge

time) is running before an impending

switching step

A double arrow symbolizes fast

switching of several branches

Connecting-in

Connecting-out

Automatic oper.

to display operation to programming to manual operation to value buffer to special functions

Programming Manual operation Service Expert mode

Repeated pressing of the "Operating Mode” key takes the user to the various menus in

sequence: Automatic operation - Programming - Manual (manual operation)-

Service - Expert mode and back.

cos 0.76 IND

j