JC MACHINERY & TOOLS INC. Quality We Trust

vi. How to change Tape Welder to Overlap Banner Welder

1. Loosen screw ( 45 ), take down tape fixed set ( 30 );

2. Loosen screw ( 46 ), take down tape limit set ( 34 );

3. Loosen inner hexagon screw ( 43 ), take down pressure roller stopper ( 35 )、tape

pressure roller ( 36 ) and drive shaft coupling cover ( 44 ), then assemble overlap

Pressure roller ( 29 )、gasket ( 42 ) and pressure roller fixed screw ( 28 ) in proper

cord;

4. Loosen hot air nozzle fixed screw ( 41 ), take down tape hot air nozzle ( 37 ), and

replace into overlap hot air nozzle ( 25 );

5. Loosen guide wheel nut ( 9 ), take down guide wheel shaft sleeve ( 10 ) and guide

wheel set ( 40 ), reassemble guide wheel set as the above pictures show;

6. Assemble belt wheel set ( 39 ), tighten belt wheel fix nut( 38 ), then assemble

circular silica belt ( 27 ).

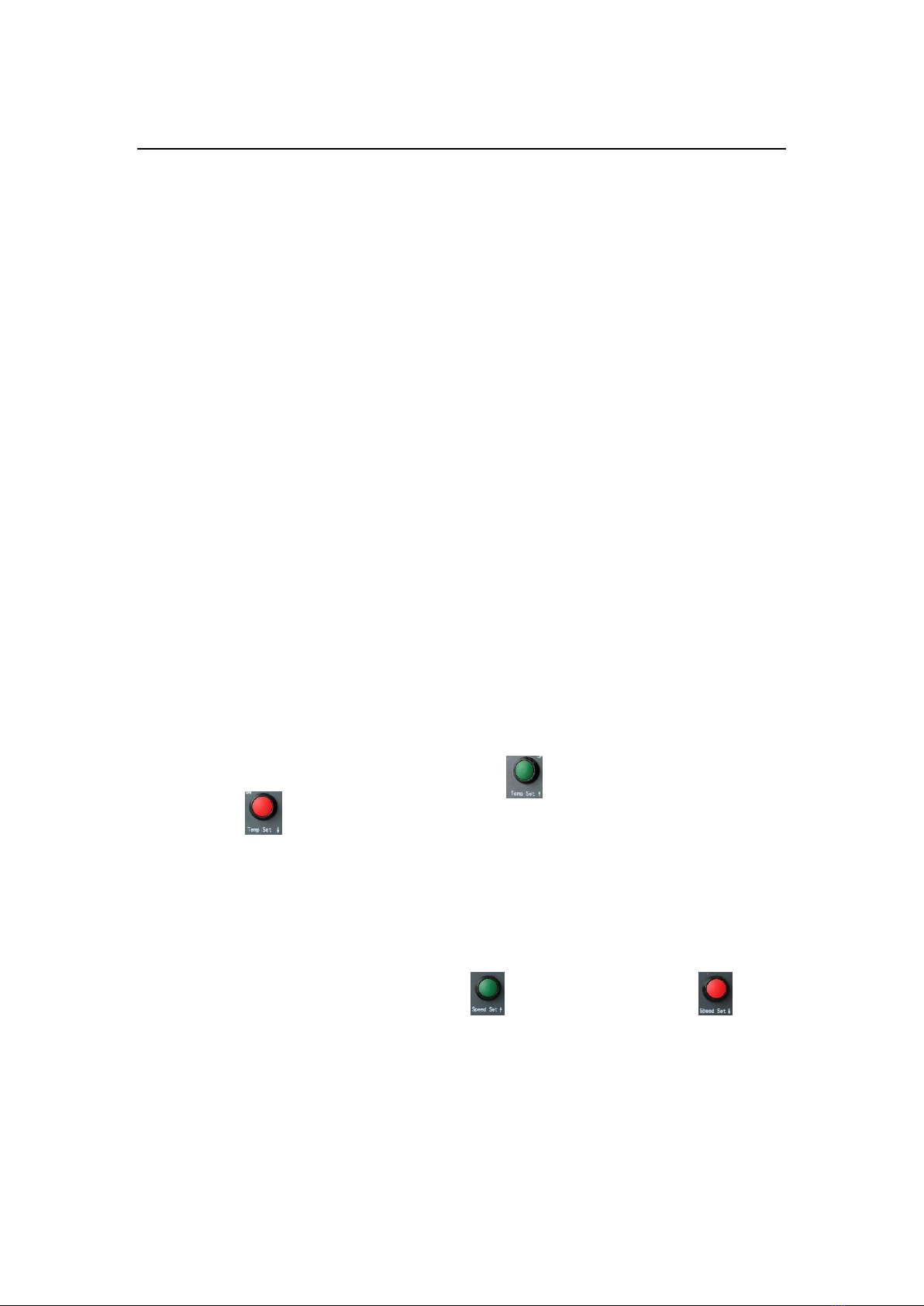

vii. Welding parameters setting

1. Welding temperature setting:

Using bottoms Temperature setting knob+ and Temperature setting

knob- on the panel to set the required temperature. You can set the

temperature according to the welding materials and the ambient

temperature. LCD display will show the set temperature and the current

actual temperature.

2. Welding speed setting:

Using bottoms Speed setting knob+ and Speed setting knob-

on the panel to set the required speed according to the welding temperature.

LCD display will show the set speed and the current actual speed.