Warranty

John Chadwick Corporation DBA J Chadwick Co

warrants the 8400K Digital Optical Micrometer

Kit, herein referred to as the product, against

defects in material or workmanship as follows;

LABOR

For a Period of two (2) years from the purchase

date, if the product is determined to be

defective, J Chadwick Co will repair the product

at no charge to the buyer. If the product is

determined by J Chadwick Co to be defective

beyond repair, a replacement will be provided.

PARTS

For a period of two (2) years from the date of

purchase, if the product or its components are

determined defective, J Chadwick Co will supply,

at no charge to buyer, new or rebuilt parts.

DISCLAIMER

(1) This warranty does not cover cosmetic

damage or damage due to acts of God, accident,

misuse, abuse, or negligence to any part of the

product.

(2) This warranty does not cover damage due to

improper operation or maintenance. Warranty is

null and void if repair or modication is attempt-

ed by anyone other than J Chadwick Co or its

authorized representatives.

Repair or replacement as provided under this

warranty is the exclusive remedy of the consumer.

J Chadwick Co shall not be liable for any inci-

dental or consequential damages for breach of

any express or implied warranty on the product.

To obtain warranty service, buyer must contact

J Chadwick Co prior to return to obtain an

authorization to return the product for service.

Buyer is responsible for providing proof of sale,

which may be required for warranty service. The

product should be returned to J Chadwick Co,

in either its original packaging or packaging

affording an equal degree of protection, with a

copy of the bill of sale.

Increase the versatility of the Optical

Micrometer with these products. Please

call for more details and pricing.

A versatile addition designed for shop and lab

environments to inspect subjects requiring more

clearance and easier accessibility (such as large

or oddly shaped parts) than the Optical Micrometer

provides when used alone.

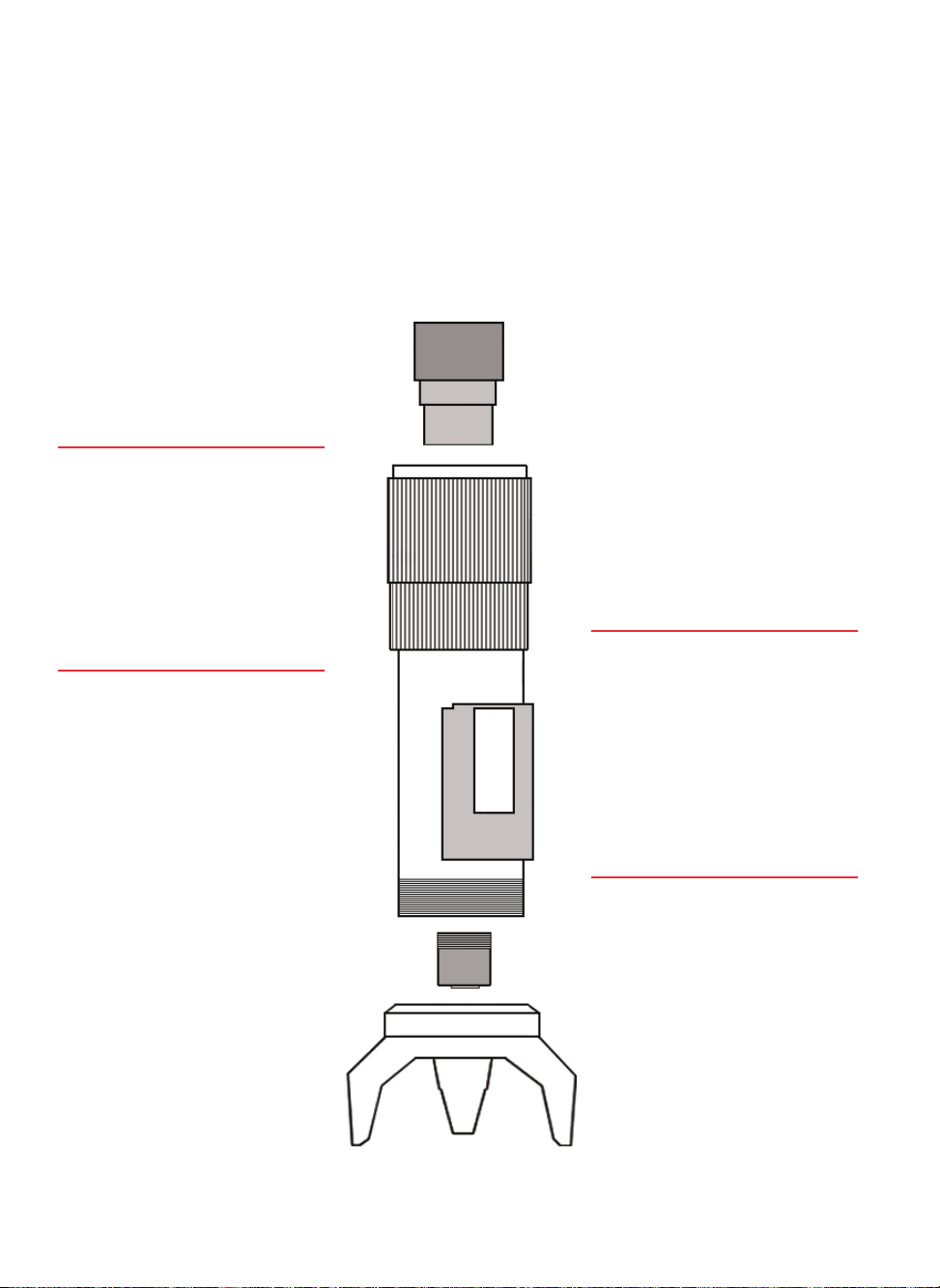

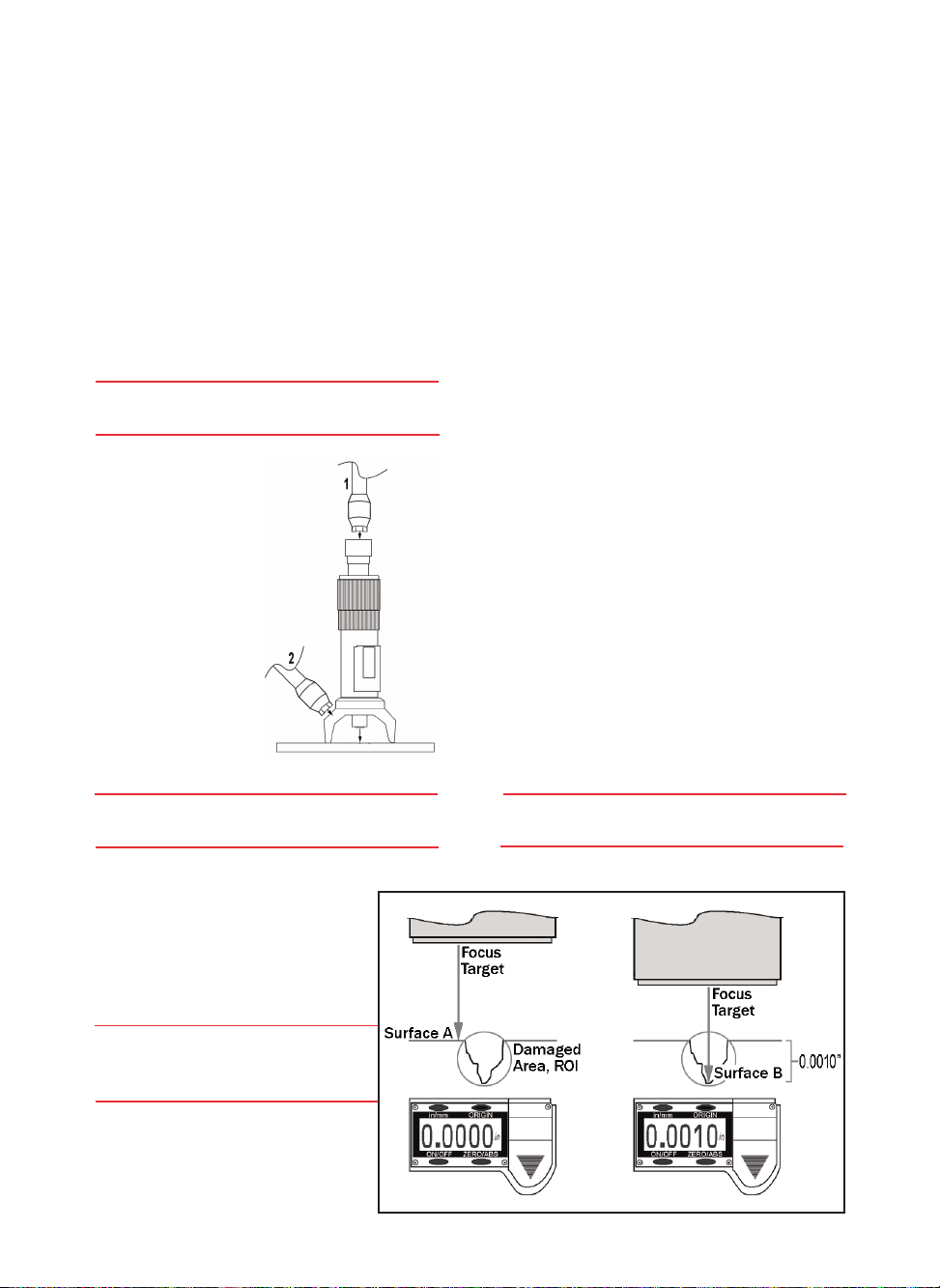

Lab Stand Kit

Model 5500

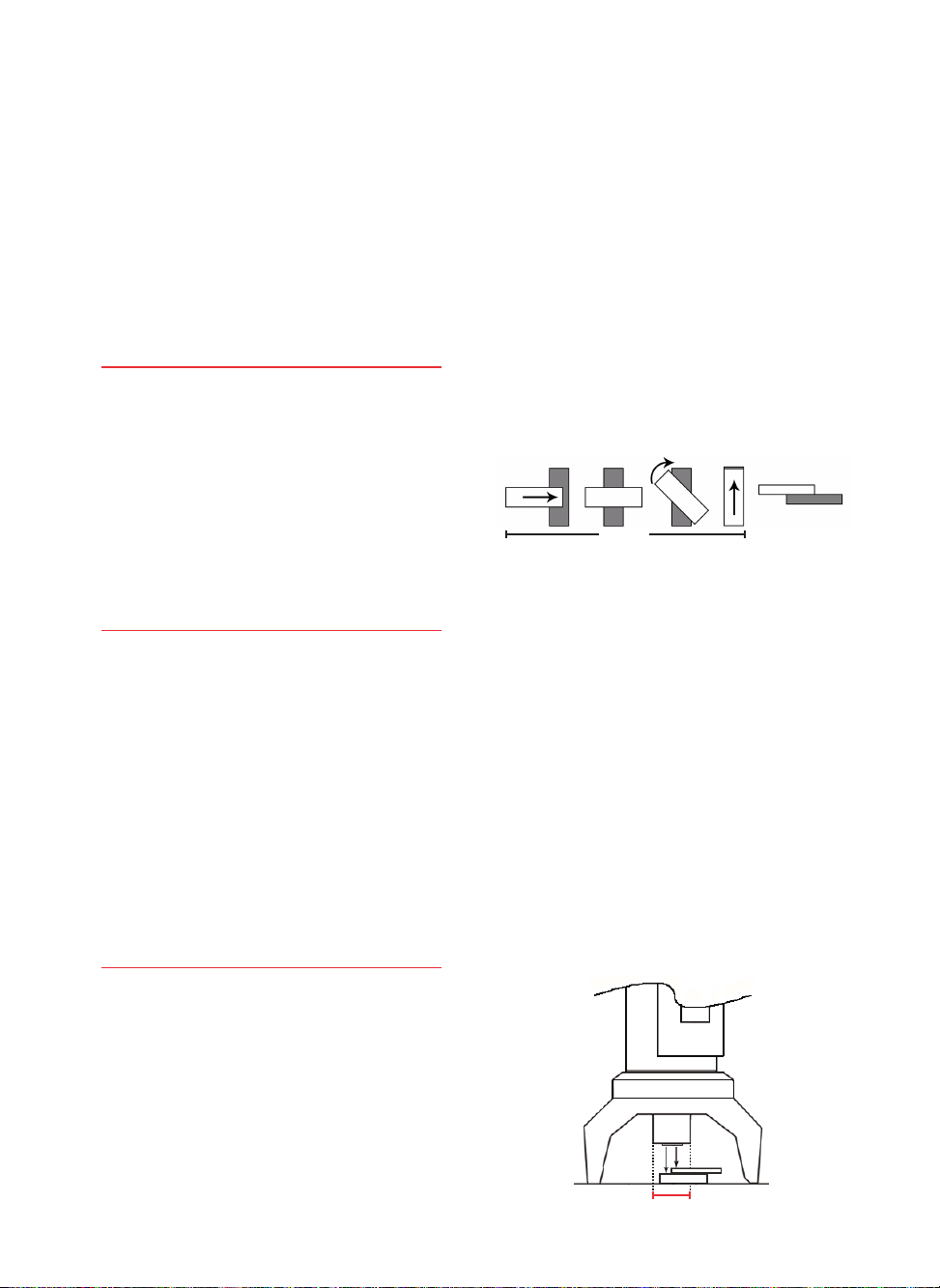

The Surface Replication Kit features Microset®

replicating compounds; the kit allows for a quick

and convenient method to obtain precise

measurements in hard-to reach places (such as the

inside of threaded holes).

Surface Replication Kit

Model 4400