JCM GLOBAL TBV-100 FSH User manual

Other JCM GLOBAL Bank Note Validator manuals

JCM GLOBAL

JCM GLOBAL DBV Series Quick setup guide

JCM GLOBAL

JCM GLOBAL RDM-100 Series Quick setup guide

JCM GLOBAL

JCM GLOBAL Taiko PUB-7 User manual

JCM GLOBAL

JCM GLOBAL VEGA Series User manual

JCM GLOBAL

JCM GLOBAL UBA Pro Series User manual

JCM GLOBAL

JCM GLOBAL iVIZION2 Series Quick setup guide

JCM GLOBAL

JCM GLOBAL WBA Series User manual

JCM GLOBAL

JCM GLOBAL TBV Series Quick setup guide

Popular Bank Note Validator manuals by other brands

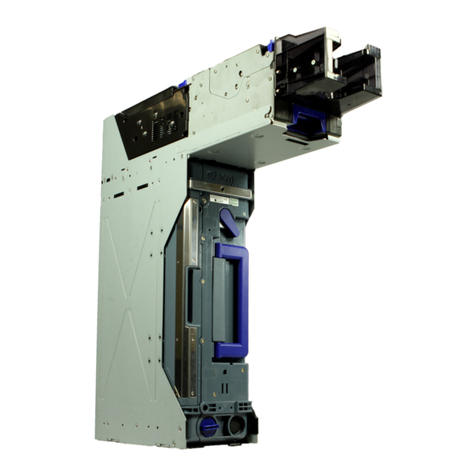

CashCode

CashCode AMZ-154 installation instructions

Global Payment Technologies

Global Payment Technologies SA-4 installation guide

PRO Intellect Technology

PRO Intellect Technology PRO-1500 LCD Series user manual

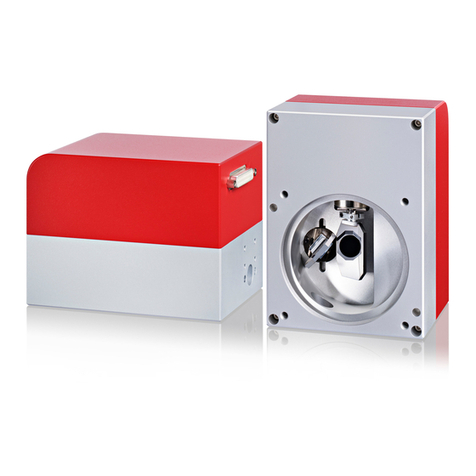

RAYLASE

RAYLASE SUPERSCAN II manual

Clas Ohlson

Clas Ohlson MD188GS instruction manual

Innovative

Innovative BV50 Operation manual