P/N 960-000175R_Rev. A {EDP #233426} © 2014, JAPAN CASH MACHINE CO., LTD.

DBV®Series

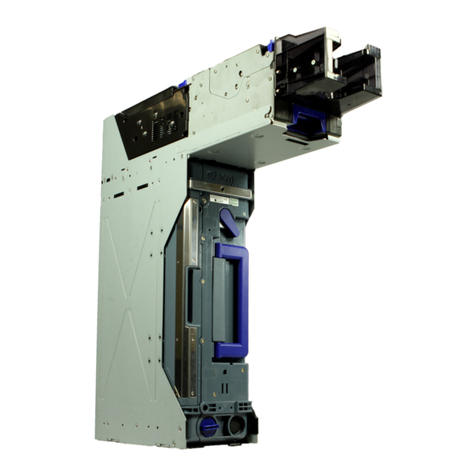

Banknote Validator (DBV-400)

Table of Contents Page

1 GENERAL INFORMATION......................................................................................1

Description.......................................................................................................................... 1

DBV-400 Unit ...................................................................................................................... 1

Model Descriptions ............................................................................................................. 2

Type Descriptions ...............................................................................................................2

Software Descriptions ......................................................................................................... 2

Precautions......................................................................................................................... 2

User Cautions ................................................................................................................................. 2

Installation Cautions ..................................................................................................................... 2

Mounting, Dismounting & Transportation...................................................................................... 3

Placing Foreign Objects into the Unit ...........................................................................................3

Preventive Maintenance ............................................................................................................... 3

Banknote Fitness Requirements..................................................................................................... 4

Primary Features ................................................................................................................4

Component Names ............................................................................................................. 5

2 SPECIFICATIONS....................................................................................................6

Technical Specifications...................................................................................................... 6

Environmental Specifications .............................................................................................. 6

Electrical Specifications ...................................................................................................... 7

Structural Specifications...................................................................................................... 7

3 INSTALLATION .......................................................................................................8

Installation Procedure ......................................................................................................... 8

Entire Unit Installation ..................................................................................................................... 8

DIP Switch Configurations .................................................................................................. 8

4 CONNECTOR PIN ASSIGNMENTS ........................................................................9

MDB Photo-Coupler Isolation Connector Pin Assignments ............................................................ 9

RS232 Connector Pin Assignments.............................................................................................. 10

TTL Connector Pin Assignments .................................................................................................. 11

ID-002 Pulse Connector Pin Assignments.................................................................................... 12

ID-044 Pulse Connector Pin Assignments.................................................................................... 13

ID-044 Serial Connector Pin Assignments.................................................................................... 14

USB Connector Pin Assignments ................................................................................................. 15

5 PREVENTIVE MAINTENANCE .............................................................................16

Retrieving Banknotes........................................................................................................ 16

Clearing a Banknote Jam.................................................................................................. 16

Cleaning Procedure .......................................................................................................... 17

Sensor and Roller Cleaning Procedure ........................................................................................ 17

Sensor and Roller Locations......................................................................................................... 18

6 STANDARD INTERFACE CIRCUIT SCHEMATICS..............................................19

Standard Interface Circuit Schematics (Continued 1)....................................................... 20

Standard Interface Circuit Schematics (Continued 2)....................................................... 21

Standard Interface Circuit Schematics (Continued 3)....................................................... 22

Standard Interface Circuit Schematics (Continued 4)....................................................... 23

Standard Interface Circuit Schematics (Continued 5)....................................................... 24

Standard Interface Circuit Schematics (Continued 6)....................................................... 25

7 OPERATIONAL FLOWCHART .............................................................................27

Operational Flowchart (Continued 1)................................................................................ 28