Ensure center of gravity load is centered

on the saddle and load is stable before

moving jack. An off-center transmission

could cause the jack to tip over.

LOWERING

Be sure all tools and personnel are clear

before

lowering load. Slowly engage

release valve pedal. Maintain control of

the rate of speed at which the load lowers

at all times.

Slowly, gently apply downward pressure

to the release valve pedal.

Never use this jack

as a workstation!

2

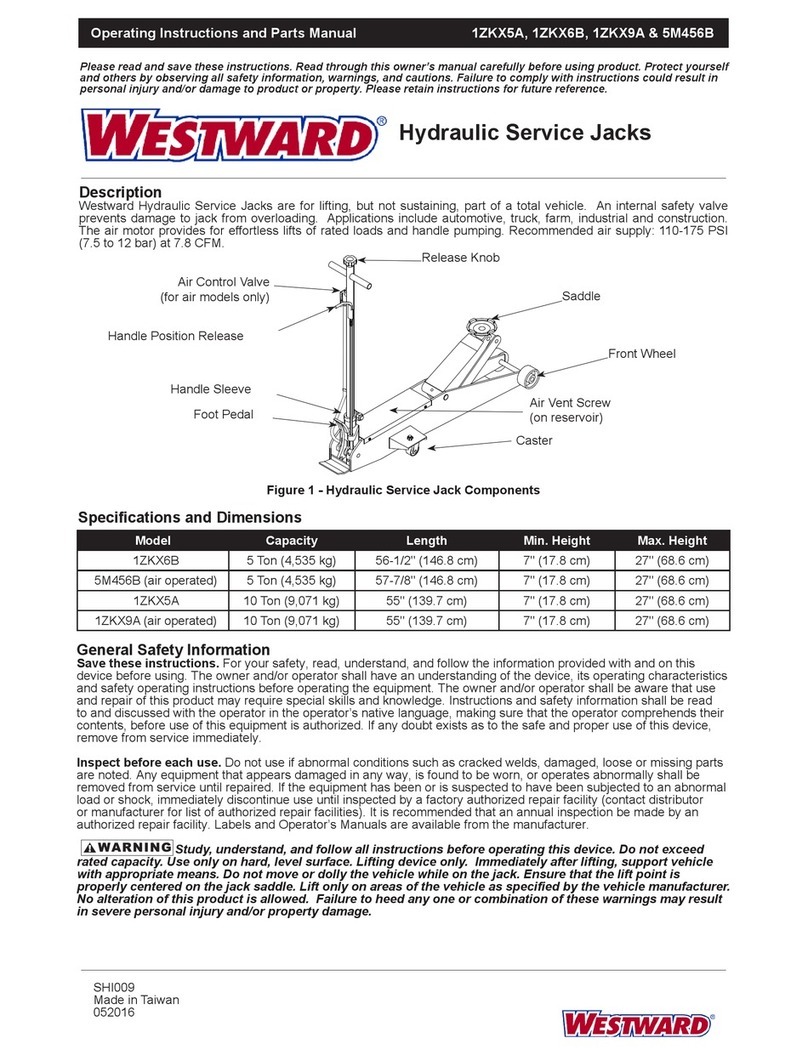

Westward Operating Instructions and Parts Manual 13X041

Maintenance

IMPORTANT: Use only good grade

hydraulic jack oil. Avoid mixing different

types of uid and NEVER use brake

uid, turbine oil, transmission uid, motor

oil or glycerin. Improper uid can cause

premature failure of the jack and the

potential for sudden and immediate loss

of load. Mobil DTE 13M or equivalent is

recommended.

ADDING OIL

1. With saddle fully lowered, set jack in

its upright, level position. Remove oil

ller screw.

2. Fill until oil is level with the oil ller

screw hole, reinstall oil ller screw.

CHANGING OIL

For best performance and longest life,

replace the complete uid supply at least

once per year.

1. With saddle fully lowered, remove oil

ller screw.

2. Lay the jack on its side and drain the

uid into a suitable container.

Note. Dispose hydraulic uid in

accordance with local regulations.

3. Set jack in its level position.

Fill until

oil is level with the oil ller screw hole,

reinstall oil ller screw.

LUBRICATION

1. A periodic lubrication of pivot points,

axles and hinges will help to prevent

rust and assure that casters and pump

assemblies move freely.

2. When used on a daily basis, air pump

should be internally lubricated before

each use. Use only good quality air tool

lubricant. If no oiler is used, pour a

teaspoon of air tool oil into the inlet of

the air supply inlet. Simply operate the

jack using the air pump in order to fully

distribute the oil.

CLEANING

Periodically check the pump piston and

ram for rust or corrosion. Clean as

needed and wipe with an oily cloth.

Note: Never use sandpaper or abrasive

material on these surfaces!

STORAGE

When not in use, store the jack with

saddle fully lowered.

Troubleshooting Chart

Jack will not lift load 1. Release valve not tightly closed 1. Ensure release valve tightly closed

2. Load is too heavy 2. Consider higher capacity jack

Jack will lift, but not maintain pressure 1. Release valve not tightly closed 1. Ensure release valve tightly closed

2. Hydraulic unit malfunctioning 2. Replace

Jack will not lower after unloading 1. Reservoir overfilled 1. Drain fluid to proper level

2. Linkages binding 2. Clean and lubricate moving parts

Poor lift performance 1. Fluid level low 1. Ensure proper fluid level

2. Hydraulic unit malfunction 2. Replace

Will not lift to full extension Fluid level low Ensure proper fluid level

Symptom Possible Cause(s) Corrective Action

BEFORE USE (Continued)

5. Pour a teaspoon of good quality, air

tool lubricant into the air supply inlet of

the lift control valve. Connect to air

supply and operate for 3-10 seconds to

evenly distribute lubricant.

Note: This unit is equipped with the

popular 1/4” NPT air coupler. When

installing a different air coupler of

your choice, ensure that thread tape

or compound is used when servicing

connections. To ensure dependable,

trouble free operation an inline air dryer

and oiler is recommended.

6. Ensure that jack rolls freely. Raise and

lower the unloaded jack throughout the

lifting range before putting into service

to ensure the pump operates smoothly.

Replace worn or damaged parts

and assemblies with factory authorized

replacement parts only.

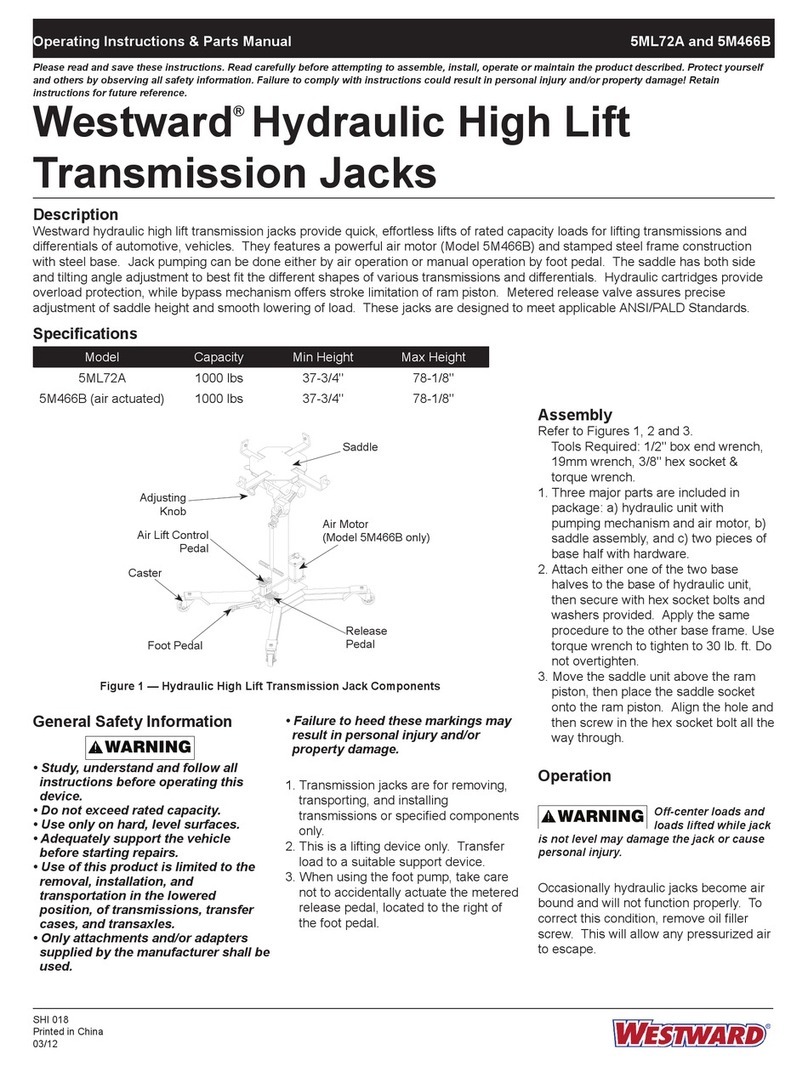

Operation

Follow the instructions for removal and

installation of transmission, transfer case

or transaxle according to the vehicle

manufacturer's service manual.

LIFTING

Pump foot pedal or press air pump pedal

until saddle reaches desired position.

Secure load with provided chains.

Note: do not operate by air and by foot

pumping at the same time.

Westward Air/Manual Telescoping

Transmission Jack

®