JENCO 3175-307A User manual

Table of contents

Other JENCO Measuring Instrument manuals

JENCO

JENCO 3177MB User manual

JENCO

JENCO VisionPlus 3177 User manual

JENCO

JENCO 6177M User manual

JENCO

JENCO 6010 User manual

JENCO

JENCO VisionPlus 6377 User manual

JENCO

JENCO 6360 User manual

JENCO

JENCO EC3840 User manual

JENCO

JENCO VisionPlus pH618N User manual

JENCO

JENCO 6177B User manual

JENCO

JENCO pH619 Installation manual

JENCO

JENCO VisionPlus EC 330 User manual

JENCO

JENCO VisionPlus pH 618 User manual

JENCO

JENCO VisionPlus pH6175 User manual

JENCO

JENCO VisionPlus pH630FA User manual

JENCO

JENCO 6179MB User manual

JENCO

JENCO 6250 User manual

JENCO

JENCO 6308CST User manual

JENCO

JENCO 3177M User manual

JENCO

JENCO 6179M User manual

JENCO

JENCO 3173 User manual

Popular Measuring Instrument manuals by other brands

multicomp pro

multicomp pro MP770291 manual

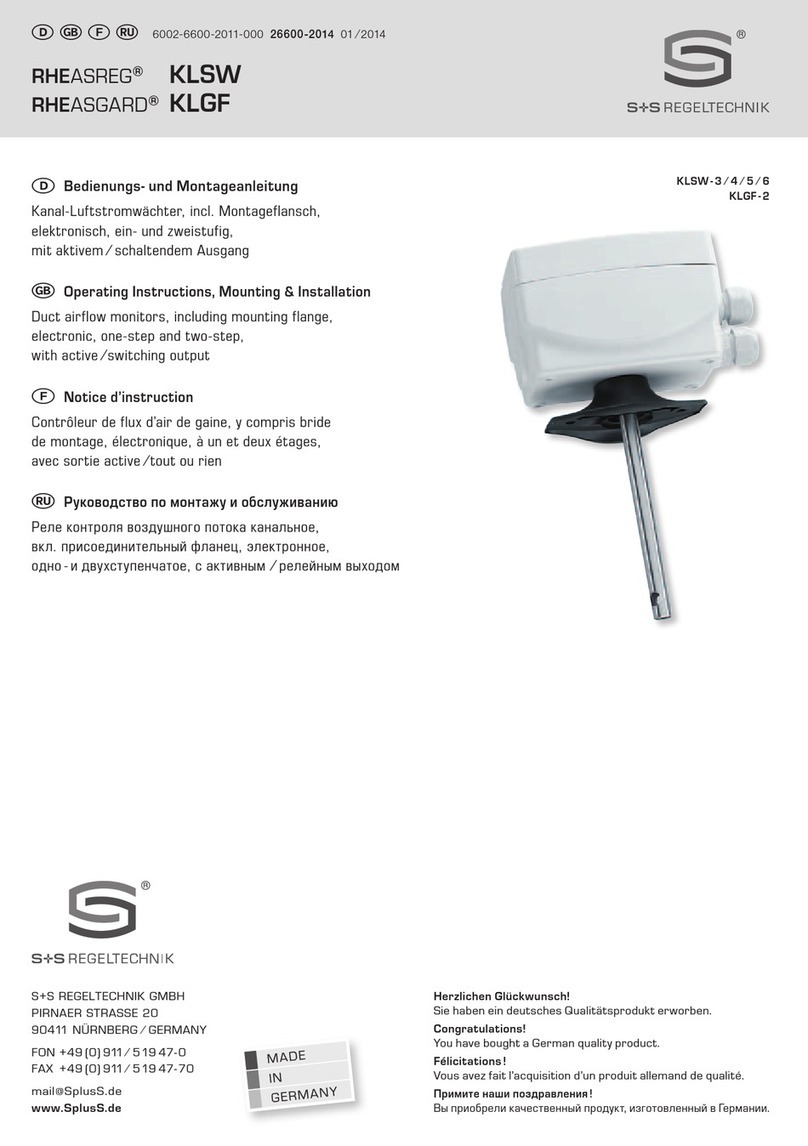

S+S Regeltechnik

S+S Regeltechnik RHEASREG KLSW-3 Operating Instructions, Mounting & Installation

S+S Regeltechnik

S+S Regeltechnik HYDRASGARD AFTF-20-VA ID Series Operating Instructions, Mounting & Installation

KYORITSU

KYORITSU KEW 6300 Driver installation

Sanyo

Sanyo MTR-5000 Specifications

Blancett

Blancett FloClean Installation instructions manual