JENCO 6360 User manual

Operation Manual

JENCO MODEL 6360

MICROCOMPUTER BASED

pH/mV/Conductivity/TDS/

Salinity/Temperature

PORTABLE METER

6360

CONTENTS

GENERAL INTRODUCTION………………....................1

INITIAL INSPECTION……...………………....................2

WATER PROOF…….……...………………....................2

INSTALLING THE BATTERIES..…………....................3

DISPLAY & KEYS FUNCTIONS…..……………...………4

A. Display ................................................................4

B. Keys...................................................................6

OPERATIONAL PROCEDURES..…….........................8

A. Preparing Standard Solutions................................8

B. Calibration..........................................................9

C. Conductivity Measurements..................................13

D. Save, Recall and Delete Data.................................13

RS232C INTERFACE OPERATION........................... 15

ERROR DISPLAYS AND TROUBLESHOOTING.......16

SPECIFICATIONS………………..……........................18

WARRANTY……………...............................................19

1

GENERAL INTRODUCTION

Thank you for selecting the 6360 meter. The 6360 is a precision tool

that measure pH, ORP, conductivity, TDS, salinity and temperature.

A built-in microprocessor stores, calculates and compensates for all

parameters related to conductivity and temperature determinations.

This unit has a waterproof IP65 case. The touch mode keys are

highly reliable with tactile and audio feedback. This meter can

operate with six AAA-size alkaline batteries or a UL/CE approved

AC adapter. Re-calibration is not required when power is restored.

The front of the meter has a large LCD that displays temperature

and either temperature compensated or non-temperature

compensated conductivity, pH, ORP, temperature compensated

TDS or salinity simultaneously along with user prompts and mode

indicators. The unit prompts the user through calibration and

measurement procedures.

The unit is also equipped with a non-volatile memory allowing the

user to store 50 different sets of readings. This unit will assign a site

number for each set of reading so the user can review the data

easily.

The model 6360 is available with a four-wire conductivity cell

(K=0.475) and a two-wire conductivity cell (K=0.1). Other features

include automatic conductivity ranging, automatic temperature

compensation, long battery life and 50/60 Hz AC noise rejection.

This unit is universal and user-friendly for field, industrial and

laboratory applications.

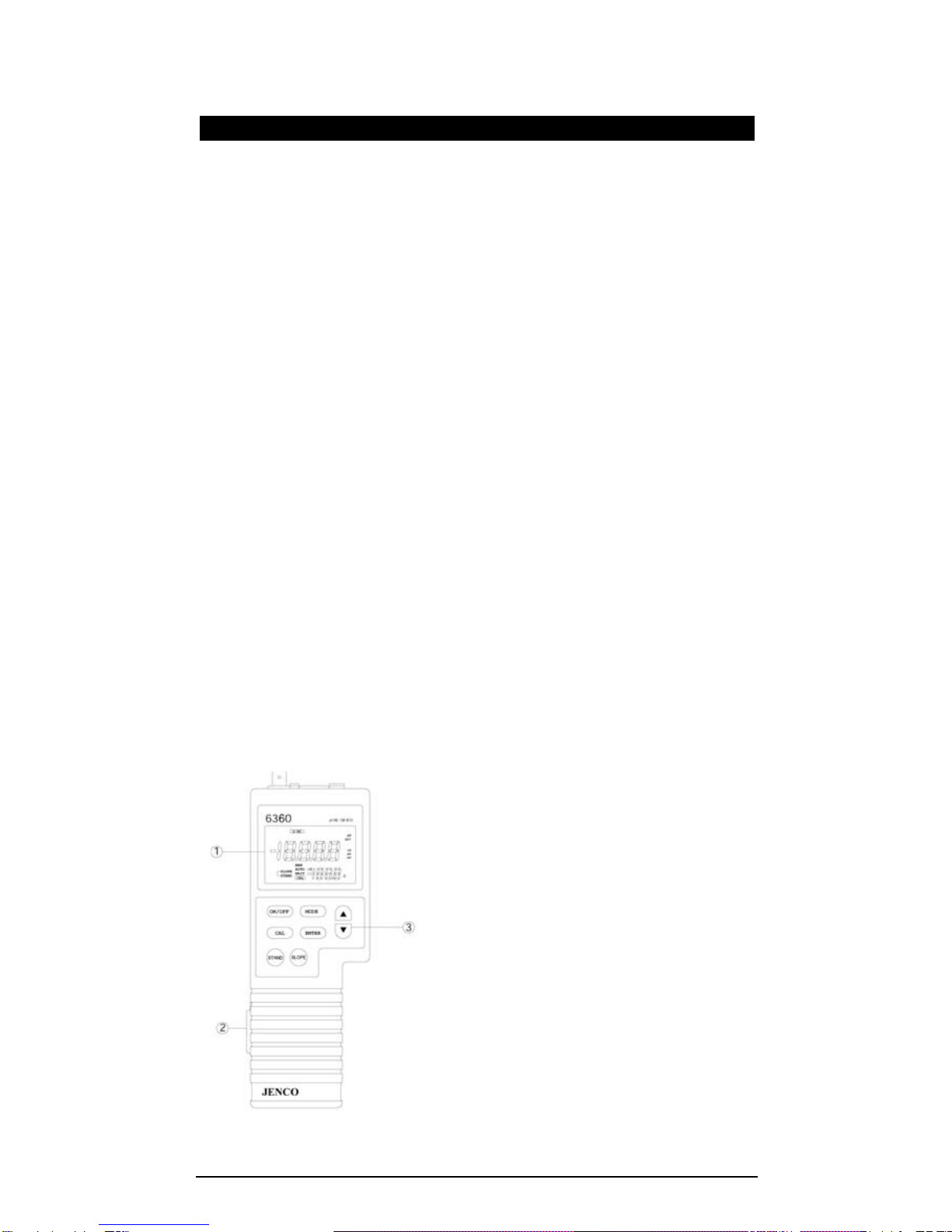

①LCD

②RS232 connector

③Keypad

2

INITIAL INSPECTION

Be careful to unpack the unit and accessories. Inspect for damages

made in shipment. If any damage is found, notify your Jenco

representative immediately. All packing materials should be saved

until satisfactory operation is confirmed.

WATER PROOF

Though this unit has a waterproof IP65 case, DO NOT use it

underwater. The watertight case prevents permanent damage to the

unit if accidentally dropped into non-corrosive solutions. Follow

these steps immediately if the unit is immersed in any solution:

1. Rinse unit carefully with distilled water. After rinsing and drying,

inspect and clean connectors to remove all contaminants that

may affect probe connections.

2. Wait for the unit and probe to dry completely before resuming

operation.

3. If the unit does not function correctly after step 1 and 2, call

JENCO for possible repair or replacement (see Warranty).

3

INSTALLING THE BATTERIES

The 6360 meter is packaged with six AAA-size alkaline batteries or

a UL/CE approved AC adapter, required for operation. To insert the

batteries into the meter, follow the procedure outlined below.

Figure 1: Battery compartment

1. Position the meter so that the bottom part of the meter is

facing up . Insert a coin in the side closure slot. Tilt the coin

and thrust it upward to open the battery compartment and

lift the closure up.

2. Remove all of the old batteries and insert a new set of

batteries ensuring the polarities are correct.

AAAbattery

BatteryCover

SIDE CLOSURE SLOT

4

DISPLAY & KEYS FUNCTIONS

A. Display

Figure 2: Active LCD screen

1. LO BAT-

Low battery indicator.

4. %-

Displays during calibration:

Indicates temperature coefficient

unit.

2. Main Display-

Display the reading of pH,

ORP, Conductivity, TDS &

Salinity.

5. Main Display Units-

“pH”: pH mode unit.

“mV”: ORP mode unit.

“uS, mS”: Conductivity mode unit.

“ppm, ppt”: TDS and Salinity

mode unit.

3. SALINITY-

Display that the unit is in the

SALINITY mode.

6. ℃/℉-

Temperature unit.

In Uncompensated Conductivity

mode, the temperature unit will

not blink.

In Compensated Conductivity

mode, the temperature unit will

blink.

5

7. Secondary Display-

Temperature reading and

site number.

10. AUTO/MAN-

“AUTO”: Used to indicate that a

temperature sensor is attached.

“MAN”: Used to indicate that a

temperature sensor is not

attached and the pH temperature

compensation is manual.

8. WAIT/CAL-

“WAIT”: Used when in pH

calibration to indicate that the

reading is not yet stable.

“CAL”: Used to indicate that

unit is in calibration mode.

11. RC-

Indicate that the unit is in recall

mode and actively displaying

saved data.

9. STAND/SLOPE-

During calibration this will

indicate which part of pH is

being calibrated, in normal

operation this will indicate

(blinking) which part of pH is

not yet calibrated.

6

B. Keys

ON/OFF-

Powers on and shuts off the meter.

MODE-

Selects display mode. In normal operation, press this

key to sequentially display pH, ORP, uncompensated

conductivity, compensated conductivity, TDS,

salinity, Recall and Erasing interface.

In calibration mode, press this key to exit the current

calibration parameter and enter into the next one.

In “rcl” and “ErAS” modes, press this key to exit “rcl”

and “ErAS” modes respectively.

UP/DOWN-

Increases or decreases the display value as desired.

In “rcl” mode, view saved data and data storage site

number by pressing these keys.

CAL-

In “Measurement” mode, press this key to enter into

“Calibration” mode.

In pH mode, press this key can enter the pH

calibration.

In conductivity or salinity or TDS mode, press this

key can change TDS ,conductivity constant ,

temperature coefficient, reference temperature,

compensated conductivity.

ENTER-

In “Calibration” mode, press this key one time to save

the current value to memory.

In “Measurement” mode, press this key 5 seconds to

save reading into the next available data storage site.

In “rcl” mode, press this key to display the last set of

saved data.

In “ErAS” mode, press this key to erase all data.

7

STAND

STAND-

During pH calibration press this key will start the

calibration of the OFFSET of the pH electrode.

Press this key with ON/OFF when the instrument is

off, the unit will acknowledge by displaying “7.00” for

(7.00,4.01,10.01) and “6.86” for (6.86,4.00 & 9.18) in

the second interface after turning on.

SLOPE SLOPE-

During pH calibration this key will start the calibration

of the SLOPE of the pH electrode.

8

OPERATIONALPROCEDURES

A. Preparing Standard Solutions

Suitable conductivity standards are available commercially, the user

can prepare them using research grade reagents.

Here are some standard solutions the user can prepare to calibrate

the probe of the model 6360.

1. Standard solution of 14.94uS at 25℃: Accurately measure out

100ml of the 147uS standard solution as in point 4. Dilute it

with 900ml of distilled water.

2. Standard solution of 147uS at 25℃: Accurately measure out

100ml of the 1413uS standard solution as in point 1. Dilute it

with 900ml of distilled water.

3. Standard solution of 1413uS at 25℃: Accurately weight out

0.746 g of research grade dried Potassium Chloride (KCL).

Dissolve in 1000ml of distilled water.

4. Standard solution of 12.90mS at 25℃: Accurately weight out

7.4365 grams of research grade dried Potassium Chloride

(KCL). Dissolve in 1000ml of distilled water.

5. Standard solution of 111.9mS at 25℃: Accurately weight out

74.264 grams of research grade dried Potassium Chloride

(KCL). Dissolve in 1000ml of distilled water.

[Note: The user can store the remaining solution in a plastic

container for one week but the air space between the cap and the

solution must be kept to an absolute minimum. Storing the excess

solution below 4℃can increase the storage life. If you have any

doubt of the accuracy of the stored solution, a fresh batch should be

prepar ed.]

9

B. Calibration

BUFFER SETTING

The buffer setting is factory selected according to user

preference, but the user can change this setting by going to

normal pH reading 【Pressing [STAND] and turn on when it’s

off.】The 6360 will acknowledge by displaying “7.00” (7.00,4.01

& 10.01) or “6.86” (6.86,4.00 & 9.18) and the text “buf” at the

first display when it’s turned on then turns to normal pH

operation.

CALIBRATION SET-UP

A. STAND AND SLOPE CALIBRATION (pH Mode)

To calibrate the stand and/or slope follow these steps:

1. Go to pH mode. Press the [CAL] key, the "CAL" icon will

appear in the lower middle of the display. At this point the

unit will display the current buffer set 7.00 for buffer set #1

(7.00, 4.01 & 10.01) or 6.86 for buffer set #2 (6.86, 4.00 &

9.18). The "STAND" icon will start to flash indicating that

the first buffer to be used is 7.00 or 6.86.

2. Place the probe in a standard buffer solution (7.00 or 6.86

buffer). Press the [STAND] key.

3. The "STAND" icon will stop flashing and stay ON. The

display will change to the pH value of the current

temperature. If a temperature probe is available, the

"AUTO" icon will turn on. If the offset ORP of the solution

is greater or less than ±100 mV (for buffer 7.00) or 108.3

mV/-91.7 mV (for buffer 6.86), then an error display will

occur. You can clean the probe and change the solution,

and press [MODE] to exit the calibration. If no error occurs

the unit will wait for the reading to stabilize for about ten

seconds (during this waiting time "WAIT" icon will blink)

then it will lock the value of the display. If during

stabilization period and the reading changes more than

pH

7.00

AUTO

SLOPE

STAND CAL 25.0 °C

10

0.01 pH, the waiting time (about 10 seconds) will restart.

In this case:

A. Change the solution.

B. Stop by pressing the [MODE].

C. Wait it out until the electrode stabilizes.

Once the display is locked ( the "WAIT" icon will

disappear), changing the input or temperature will not

change the pH display.

4. The "SLOPE" icon will start to flash indicating that the

instrument is ready for the second buffer calibration. You

can press [MODE] to exit for a one-point pH calibration.

5. If you are doing a two-point calibration, change the

solution now.

Press [SLOPE]. The "SLOPE" icon will stop flashing and

stay ON. If the ORP input is greater than 30% or less than

-30% of the ideal slope of this buffer then an error display

will occur. You can change solution now or you can press

[MODE] to abort the SLOPE Calibration. If no error occurs

the unit will wait for the reading to stabilize (during this

waiting time "WAIT" icon will blink) then it will lock the

value of the display. If during stabilization period and the

reading changes more than 0.01 pH then this waiting time

(about 10 seconds) will restart .

In this case :

A. You can change the solution.

B. Just abort by pressing [MODE].

C. Wait it out until the electrode stabilizes.

Once the display is locked (the "WAIT" icon will disappear)

changing the input or temperature will not change the pH

display.

You just finished a two-point pH calibration. Press [MODE]

to return you to normal operation. The instrument is now

ready for pH measurements.

B. COND CALIBRATION

Calibration setup contains five parameters: TDS, Cell,

Temperature Coefficient, Temperature reference and

Conductivity Calibration with Temperature reference. To access

these sections:

1. Connect the conductivity probe which model is either the

101C (K=0.475) or the 109L(K=0.1) to the unit and turn it

on. The screen will display the “C0.5” “C0.1” icon and the

cell constant of the previous calibration. (Factory default

is set at K=0.475).

2. Allow temperature reading to stabilize, in the mode of

either temperature compensated or non-temperature

compensated conductivity, temperature compensated

TDS or salinity, press “CAL” key to enter the calibration

11

mode. The “CAL” icon appears on the LCD. Press “UP”

and “DOWN” key to change the value, press “ENTER” key

to save the setting and go into the next setting. If pressing

“MODE” key instead of “ENTER” key, the setting will be

given up and go into the next setting.

TDS

TDS is determined by multiplying conductivity (mS) by a TDS

factor. The default factor value is 0.65. To change the TDS

factor, use the “UP” and “DOWN” keys to adjust the value

between 0.30 and 1.00. Press “ENTER” key to save the new

value and the unit will go into the next calibration parameter

automatically. If pressing “MODE” key instead of “ENTER” ,

any changes made will be cancelled and the previous

calibration settings will be retained.

CELL

Press “UP” and “DOWN” keys to select cell constant “C0.5” or

“C0.1” on the secondary display. Press “ENTER” key to

confirm selection, then the unit will go into the next calibration

parameter automatically. If “MODE” key is pressed instead of

the “ENTER” key, any changes made will be cancelled and

the previous calibration settings will be retained.

0.65

CAL TDs

0.475

CAL c0.5

12

Temperature Coefficient

The unit uses the temperature coefficient to calculate

temperature compensated conductivity. The default value is

1.91%. To change the temperature coefficient, use the “UP”

and “DOWN” keys to adjust the value between 0 and 4.00%.

Press “ENTER” to save the new value and the unit will go into

the next calibration parameter automatically. If “MODE” is

pressed instead of “ENTER”, any changes made will be

cancelled and the previous calibration settings will be

retained.

Temperature Reference

The unit uses the temperature reference value to calculate

temperature compensated conductivity. The default value is

25℃. To change the temperature coefficient , use the “UP”

and “DOWN” keys to adjust the value between 15℃to 25℃.

Press “ENTER” key to save the new value and the unit will go

into the next calibration parameter automatically. If “MODE”

key is pressed instead of the “ENTER” key, any changes

made will be cancelled and the previous calibration settings

will be retained.

%

1.91

CAL 25.0 ℃

25.0 ℃

CAL 25.0 ℃

13

Conductivity Calibration

(a) Immerse the probe in a standard of known conductivity,

preferably a standard in the middle range of the solutions

to be measured. Immerse the probe (at least 2” to 3” or

5~7cm from the tip) into standard solution without touching

the sides of the container. Shake the probe lightly to

remove any air bubbles trapped in the conductivity cell.

(b) Allow temperature to stabilize. The message “rAGE”

(range) may appear briefly on the display indicating

auto-ranging; this is normal. After temperature stabilization,

use the “UP” and “DOWN” keys to adjust the conductivity

value to that of the conductivity standard at 25℃. Press

“ENTER” key to calibrate. Calibration is now complete and

the unit will switch to “Measurement” mode automatically.

C. Conductivity Measurements

1. Turn on the unit. Place the probe in the solution to be

measured. Immerse the probe (at least “2 to 3” or 5~7cm

from the tip) in the sample solution. Shake the probe

lightly to remove any trapped air bubbles in the

conductivity cell.

2. Press “MODE” key to enter into the measurement mode.

The message “rAGE” (range) may appear briefly on the

display indicating auto-ranging; this is normal. Allow

temperature to stabilize read the value.

D. Save, Recall and Delete Data

a. Saving readings to memory.

1. In the modes of either temperature compensated or

non-temperature compensated conductivity, pH, ORP,

temperature compensated TDS or salinity, hold the “ENTER”

key for 5 seconds to save data. The “Save” icon with the

corresponding site number will lit up for a brief moment to

indicate a successful data to save.

oUer us

CAL 25.0 ℃

14

2. If the “Full” icon is displayed, it means that all 50 data saving

sites are used up. No new data can be saved until existing

saved data are deleted.

b. Recalling readings from memory.

1. To recall saved data, press “ENTER” key to go into the “rcl”

mode.

2. Press the “UP” or “DOWN” keys to select the storage site

number and Press “ENTER” key to go into the interface,“RC”

icon will be displayed at the top left corner. Press “ENTER” key

to change the interface of pH, ORP, conductivity, TDS, salinity

and temperature

3. Press “MODE” key to exit “rcl” mode.

c. Deleting

data.

In the “ERAS” mode, hold the “ENTER” key for 5 seconds, the

unit will display “done” icon that all the save data are deleted.

The unit will go into the pH mode automatically.

R C L

0 1

E R A S

15

RS232C INTERFACE OPERATION

A. INTRODUCTION

This section assumes you are familiar with the basics of data

communication, the RS232 interface, a rudimentary knowledge and

a copy of the more popular Windows® computer languages capable

of using a an RS232 port.

A simple program must be written in order to send your

command and receive data from the meter.

B. PREPARING THE METER

This meter comes equipped with an RS232C interface. This

meter communicates with a PC computer (100% IBM PC/AT

compatibles) through a DB-9 interface connector. A standard

RS232C cable used for interconnecting two IBM PC/ATs can also be

used for this operation.

After you have connected the cable and turned on both the

meter and the computer, you are now ready for the software

preparation.

C. SOFTWARE

A demo program written in Visual Basic® 6.0 and the source

are included in the accompanying disk. Read the “Model 6360

RS232 MODBUS RTU PROTOCOL.doc” to understand the

procedure used inside the demo program.

16

ERROR DISPLAYS AND TROUBLESHOOTING

MAIN

LCD

display

SECOND

-ARY

LCD

display

MODE Possible cause(s)

[Action(s)]

OVEr ovr pH

Temperature > 100.0°C

or temperature probe is broken.

[Replace temperature probe.]

OVEr ovr

a. temperature

compensated

Conductivity

b. TDS

c. Salinity

c. Cond-Cal

Temperature > 100.0°C.

[Bring solution to a lower

temperature.]

[Use a temperature probe.]

Normal

display ovr

non-temperature

compensated

conductivity

Temperature > 100.0°C.

[Replace temperature probe.]

Undr udr

a. pH

b. pH-Cal

Temperature < -5.0°C.

[Bring buffer/solution to a higher

temperature.]

OVer udr

a. Conductivity

b. Cond-Cal

c. Salinity

a. Temperature < -5.0°C

b. Temperature probe is defective.

c. Cond>200mS(k=0.475)

Cond>200μS(k=0.1)

[Bring solution to a higher

temperature or use a temperature

probe or change the solution.]

OVer -5.0~

100.0°C pH pH>16.00 .

[Recalibrate.]

OVer 0.0 ~

60.0°C pH-Cal

pH>16.00.

[Use a new buffer solution.]

[Replace the electrode.]

OVer 0.0 ~

60.0°C

a. pH-Cal-STAND

b. pH-Cal-SLOPE

a. Offset mV> 30% of ideal offset.

b. Slope mV> 30% of ideal slope.

[Use a new buffer solution or

replace electrode.]

OVer > 60.0°C pH-Cal

Buffer temperature>60.0°C.

[Bring buffer to a lower

temperature.]

OVer -5.0~

100.0°C

a. Conductivity

b. Cond-Cal

c. pH-Cal

Cond>200mS(k=0.475)

Cond>200μS(k=0.1)

When in pH-Cal mode, Buffer

temperature>60.0°C and <100.0°C

[Check calibration.]

[Check temperature reference,

and temperature.]

17

OVer -5.0~

100.0°C ORP ORP input > 1999 mV

OVer -5.0~

100.0°C Salinity

Salinity > 80.0 ppt.

[Check calibration.]

[Check temperature reference and

temperature coefficient.]

Undr -5.0~

100.0°C

Cond-Cal - after

pressing [Enter]

New cell constant > 1.3 (k=1.0).

[Use a new standard solution or

clean/replace probe.]

Undr -5.0 ~

100°C

a. pH

b. pH-Cal

pH < -2.00.

When pH-Cal temperature>-5°C

and <-5°C

[Recalibrate or use a new standard

solution.]

Undr 0.0 ~

60.0°C

a. pH-Cal-STAND

b. pH-Cal-SLOPE

a. Offset mV< 30% of ideal offset.

b. Slope mV< 30% of ideal slope.

[Use a new buffer solution.]

[Replace electrode.]

Undr < 0.0°C pH-Cal

Buffer temperature < 0.0°C.

[Bring buffer to a higher

temperature.]

[Replace temperature probe.]

Undr -5.0~

100.0°C

Cond-Cal - after

pressing [Enter]

New cell constant < 0.7 (k=1.0).

[Use a new standard solution.]

[Clean/replace probe.]

Undr -5.0~

100.0°C ORP ORP input < -1999 mV

[Note: If the unit still does not perform normally after the above

measures are taken, call Jenco Service Department.]

18

SPECIFICATIONS

Display Range Resolution Accuracy

pH -2.00~16.00 0.01pH ±0.01pH±1digital

ORP -1999~1999mV 1mV ±0.1% FS±1digital

Conductivity

K=0.475

0.0 to 475.0uS/cm

475 to 4750uS/cm

4.75 to 47.50mS/cm

47.5 to 200.0mS/cm

0.1uS/cm

1uS/cm

0.01mS/cm

0.1mS/cm

±0.5% FS

Conductivity

K=0.1

0.00 to 99.99uS/cm

100.0 to 200.0uS/cm

0.01uS/cm

0.1uS/cm ±0.5% FS

TDS

K=0.475

0.0 to 475.0 ppm

475 to 4750 ppm

4.75 to 47.50 ppt

47.5to 200.0 ppt

0.01 ppm

1 ppm

0.01 ppt

0.1 ppt

±0.5% FS

TDS

K=0.1

0.00 to 99.99 ppm

100.0to 200.0ppm

0.01 ppm

0.1 ppm ±0.5% FS

Salinity 0.0 to 80.0ppt 0.1ppt ±1% FS

Temperature -5.0 to 100.0 °C 0.1 °C ±0.3°C±0. 1°digital

Reference Temperature 15.0 to 25.0 °C

Temperature Coefficient 0.0% to 4.0% default: 1.91%

Cell Constant Four-wire cell: K=0.475 and two-wire cell:

K=0.1

TDS Constant Range 0.30 to 1.00 default: 0.65

Power six AAA-size alkaline batteries or a UL/CE

approved AC adapter

Datalogging capabilities 50 data sets

Automatic shut off function 10 minutes of non-use

Audio Feedback All Touch Keys

Display(Conductivity/ Salinity

/TDS/ORP: Temp) 12mm : 8mm high LCD

Ambient Temperature Range 0 to 50 °C

Relative Humidity At 90% RH

Case IP65 waterproof

Dimensions (W x D x H) 241mm x 86mm x 72mm

Weight 470 grams

(Batteries included)

Table of contents

Other JENCO Measuring Instrument manuals

JENCO

JENCO 6179M User manual

JENCO

JENCO 9031M User manual

JENCO

JENCO VisionPlus pH630FA User manual

JENCO

JENCO 6377MB User manual

JENCO

JENCO 6177B User manual

JENCO

JENCO VisionPlus pH618N User manual

JENCO

JENCO 6230M User manual

JENCO

JENCO 3020M User manual

JENCO

JENCO 6010M User manual

JENCO

JENCO VisionPlus pH6810 User manual

JENCO

JENCO 6011B User manual

JENCO

JENCO pH619 Installation manual

JENCO

JENCO 6250 User manual

JENCO

JENCO EC3840 User manual

JENCO

JENCO 3175-307A User manual

JENCO

JENCO 6011M User manual

JENCO

JENCO 6010N User manual

JENCO

JENCO VisionPlus 9020M User manual

JENCO

JENCO VisionPlus EC 330 User manual

JENCO

JENCO VisionPlus 3177 User manual