JENCO EC3840 User manual

Table of contents

Other JENCO Measuring Instrument manuals

JENCO

JENCO 6230M User manual

JENCO

JENCO 6177B User manual

JENCO

JENCO 6250 User manual

JENCO

JENCO 6011B User manual

JENCO

JENCO VisionPlus pH 618 User manual

JENCO

JENCO VisionPlus 3177 User manual

JENCO

JENCO 6179MB User manual

JENCO

JENCO pH610N User manual

JENCO

JENCO 3173 User manual

JENCO

JENCO 6010 User manual

JENCO

JENCO 6308CST User manual

JENCO

JENCO 6179M User manual

JENCO

JENCO VisionPlus EC 330 User manual

JENCO

JENCO VisionPlus 6377B User manual

JENCO

JENCO VisionPlus pH630 User manual

JENCO

JENCO 3175-307A User manual

JENCO

JENCO VisionPlus pH618N User manual

JENCO

JENCO 6377MB User manual

JENCO

JENCO VisionPlus pH618N User manual

JENCO

JENCO 3011M User manual

Popular Measuring Instrument manuals by other brands

KROHNE

KROHNE BATCHFLUX 5015 K Series Installation and operating instructions

Sartorius

Sartorius MA160 operating instructions

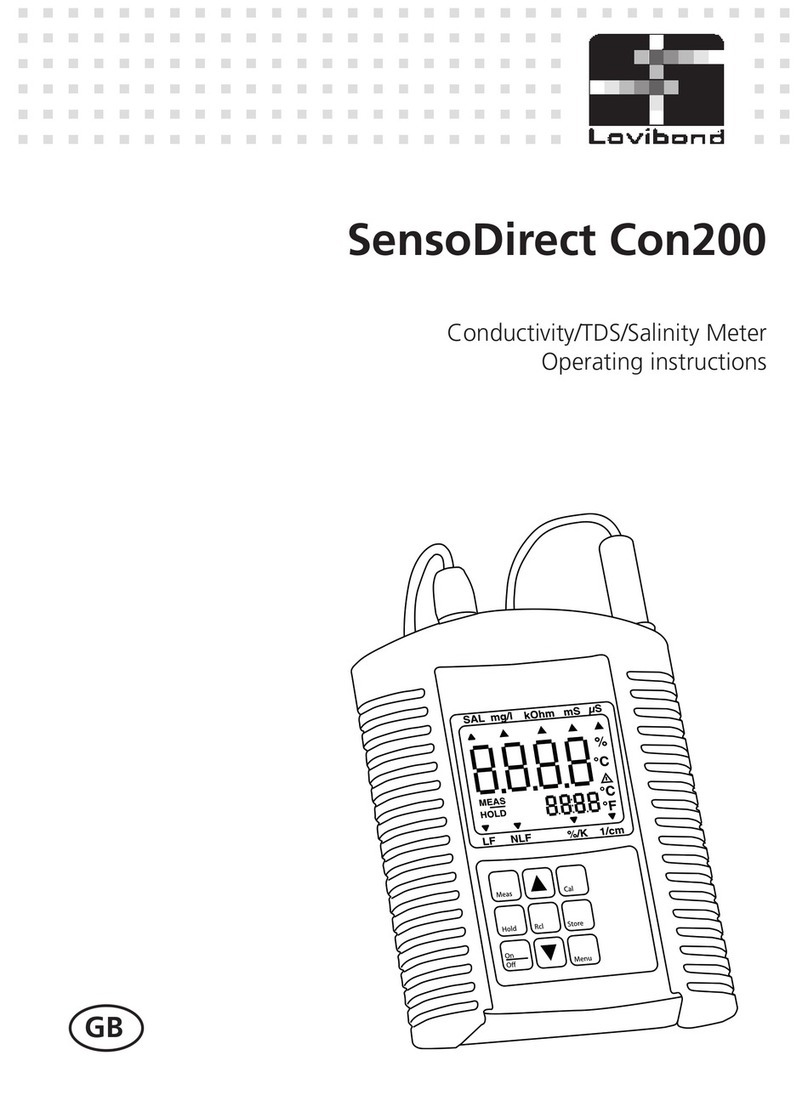

Lovibond

Lovibond SensoDirect Con200 operating instructions

Minolta

Minolta FLASH METER VI instruction manual

Ditel

Ditel JUNIOR JR-C user manual

Black & Decker

Black & Decker Autotape ATM100 instruction manual