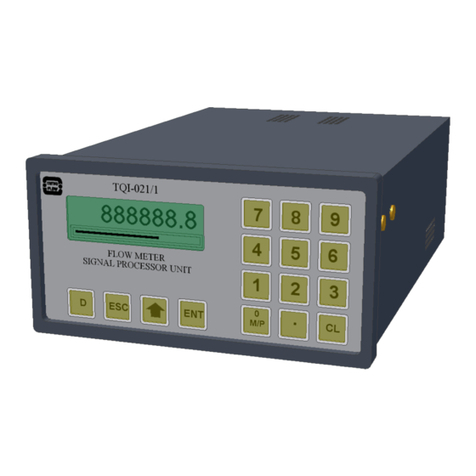

JENCO 3321 User manual

Other JENCO Measuring Instrument manuals

JENCO

JENCO 6230M User manual

JENCO

JENCO VisionPlus 6177 User manual

JENCO

JENCO 6308CST User manual

JENCO

JENCO VisionPlus EC 330 User manual

JENCO

JENCO 3011M User manual

JENCO

JENCO VisionPlus pH630 User manual

JENCO

JENCO VisionPlus pH630FA User manual

JENCO

JENCO VisionPlus pH 618 User manual

JENCO

JENCO 6010M User manual

JENCO

JENCO VisionPlus 9020M User manual

JENCO

JENCO VisionPlus pH6810 User manual

JENCO

JENCO pH619 Installation manual

JENCO

JENCO 3177MB User manual

JENCO

JENCO VisionPlus 3177 User manual

JENCO

JENCO 6010 User manual

JENCO

JENCO VisionPlus pH6175 User manual

JENCO

JENCO VisionPlus pH618N User manual

JENCO

JENCO 6177M User manual

JENCO

JENCO 6250 User manual

JENCO

JENCO VisionPlus 6377 User manual