4. Instructions for Use

(1) Install the flow meter perpendicularly at a level, stable location.

(2) Use the tubing to connect the sampling equipment, flow meter, and suction pump.

(3) Start the suction pump, and measure the suction flowrate. Adjust the flowrate with the needle

valve. The flowrate reading position is the center of the ball.

Note: The float position will change vertically depending on the ambient temperature and air

pressure. It will be particularly affected by an increase in pressure loss due to an

accumulation of dust on the sampling filter.

For flowrate correction procedures, refer to the Work Environment Measurement

Guidebook.

5. Cautions for Use

•Install the flow meter perpendicularly at a level, stable location. The location must not be

subject to irregular vertical motion or rotation, and the float must not touch the taper tube.

Ensure that it is perpendicular before use.

•If dust or moisture gets into the gap between the taper tube and the float, it may lead to

clogging, or destabilize the float. When using the flow meter, connect the sampling

equipment, and ensure that dust does not enter the flow meter.

•Excessive pressure exceeding the upper measurement limit for the pressure gauge will

increase measurement errors and lead to breakdowns.

•Exposure to vibrations and pulsations for an extended period will increase measurement

errors and lead to breakdowns.

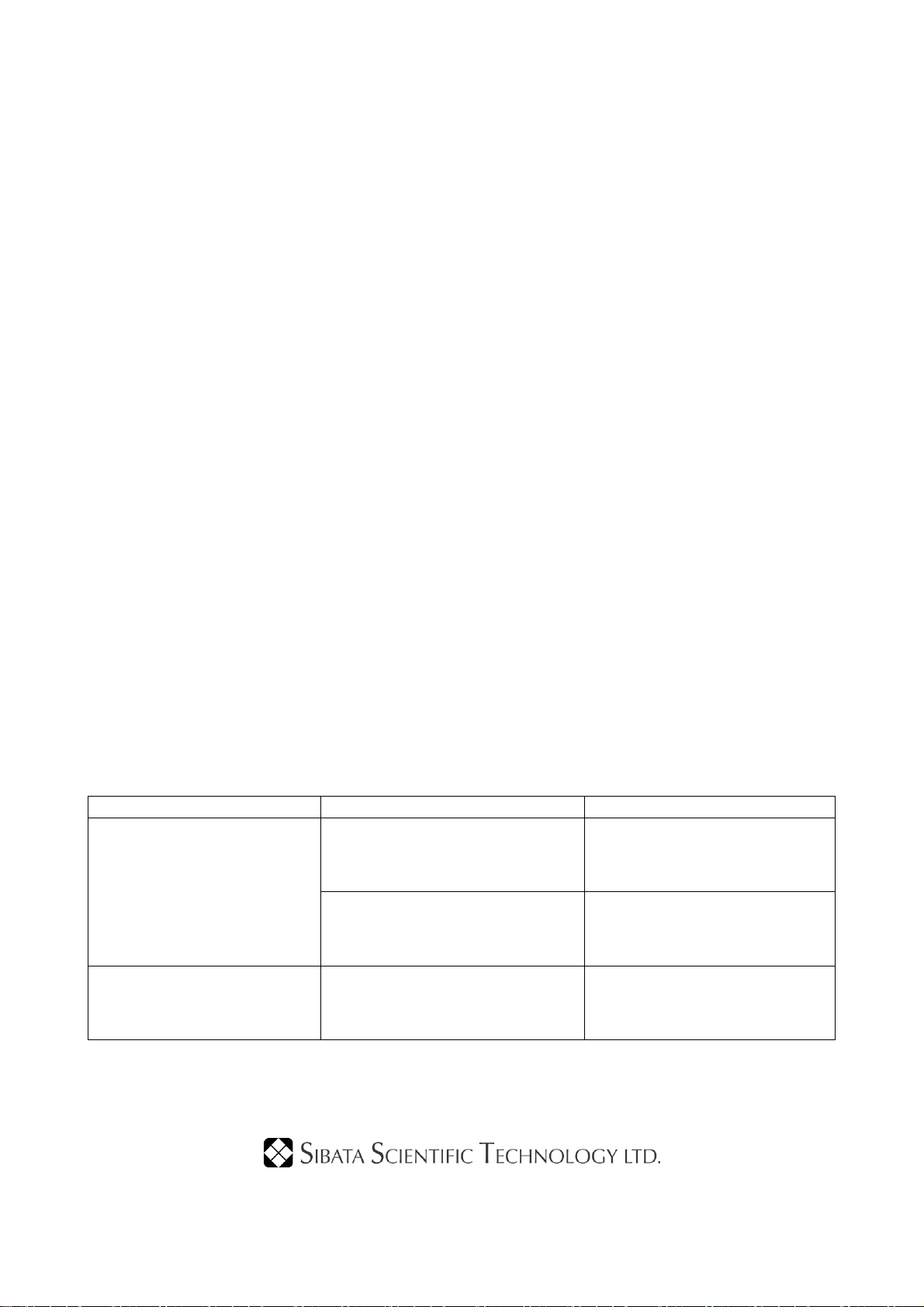

6. Troubleshooting

Before initiating repairs, inspect the instrument one more time.

If it is still malfunctioning, contact your Shibata representative.

Problem Cause Remedy

A tube is not connected properly. Connect the tubes properly.

There is no suction, or the

flowrate is low.

A tube has a kink in it. Ensure that the tubes are

straight.

The flow position is unstable. The flow meter is not installed

perpendicularly.

Install it perpendicularly at a

level, stable location.

13.12.25H(01)

1-1-62, Nakane, Soka, Saitama, 340-0005 Japan

TEL : 81-48-933-1574 FAX : 81-48-933-1587

URL : http://www.sibata.co.jp/