Jerguson JMT Series Guide

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

2

Warranty

Seller warrants goods manufactured by it will be free from defects in material and workmanship for one (1)

year following the date of shipment. If any of the Goods are found by Seller to be defective, such Goods will,

at the Seller's option, be replaced or repaired at Seller's cost. The parties hereto expressly agree that Buyer's

sole and exclusive remedy against the Seller shall be for the repair or replacement of defective Goods as

provided herein. The exclusive remedy shall not be deemed to have failed of its essential purpose so long as

the seller is willing and able to repair or replace defective Goods in the prescribed manner.

Contact Factory for full copy of Terms and Conditions/Warranty.

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

3

Table of Contents

1. Unpacking

1.1. Storage and Handling

1.2. Factory Mounted on Jerguson Magnicator

1.3. Notice of Pre-Configuration

1.4. ESD Warning

2. Installation on Existing Magnetic Level Indicator (MLI)

2.1. Tools Required

2.2. Vibration Kit (if Required)

2.3. Temperature/Insulation Safeguards

2.4. General Preparation Tips

2.5. Installation Procedure

3. Wiring

3.1. Hazardous Location Safety

3.2. Proper Grounding

3.3. Recommended Loop Wiring (Diagram)

4. Configuration

4.1. Operation Screen

4.2. Menu Screens

5. Troubleshooting

5.1. Theory of Operation

5.2. Transmitter Adjustment and Sources of Malfunction

5.3. Spare Parts

5.4. Measurement Troubleshooting

6. Glossary/Other

6.1. Appendices

6.2. General Specifications

6.3. Hazardous Location Ratings and Markings

6.4. Full Menu/Command List

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

4

Section 1: Unpacking

1.1 Storage and Handling

1. Upon receipt of materials, open crates / boxes and inspect all materials to ensure no damage

has occurred during transit. If damage is noted, file claim with Clark-Reliance or the applicable

freight carrier, depending on shipping terms.

2. Replace and fasten down lid of crate / box.

3. Materials shall remain inside of the crate / box until it is ready to be installed.

4. Store all materials in a dry, clean, indoor environment, protected from the elements, flooding,

corrosive fumes or other physical damage.

5. Materials should be stored in a place where they can neither fall nor be struck by falling

objects.

6. Storage area should be climate (humidity) controlled environment to prevent condensation

and corrosion.

a. Storage temperature for shipments that include transmitters should be 40°F to 104°F

(4.5°C to 40°C).

7. Outdoor storage is not recommended. Damage caused by outdoor storage or other negligent

storage is not covered by Clark-Reliance Warranty.

a. JMT Transmitters ship with NPT type plugs to prevent water ingress. These plugs

should not be considered watertight, nor are meant to prevent ingress from exposure

to weather.

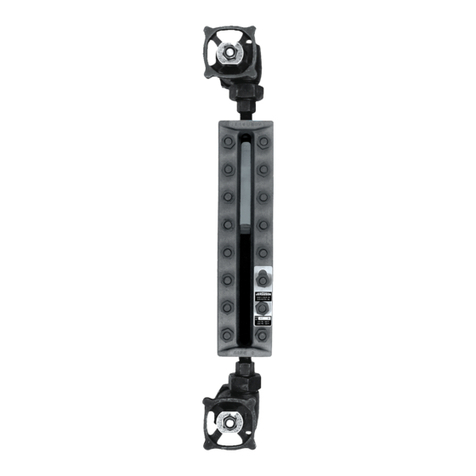

1.2 Factory Mounted on Jerguson®Magnicator®

**Do not discard any packaging until unit is fully installed and operational**

Refer to Jerguson Magnicator IOM M500.01 for more information.

If your JMT Magnetostrictive comes pre-installed on a Jerguson Magnicator, please perform the

following checks to ensure there was no damage during shipping.

1. Ensure brackets are secure and transmitter head and sensor probe are free from damage,

including bends of impact damage.

2. Check the ‘4mA’ and ‘20mA’ stickers on the sensor probe are in place and line-up with the lower

and upper side process connections. If your Magnicator is a configuration that does not have

either one or both side connections or has a measuring range that does not match either one or

both side process connections, ensure the ‘4mA’ lines up with the lowest point of the measuring

range (whether inches, %, mm or otherwise) on the flag indicator and the ‘20mA’ corresponds

with the span, i.e., full measuring range.

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

5

1.3 Notice of Pre-Configuration

Your JMT Magnetostrictive comes pre-configured from the factory to work as designed based on the

application and parameters provided at time of order. This typically means the measurement range of

the transmitter and MLI it is installed on match. If a shorter range is required, refer to the Rerange

features in section 4.2.6. If it is necessary to reposition the head from the top to bottom or vice-versa,

use the Flip Transmitter setting in 4.2.7 and perform the Trim command in section 4.2.8.

1.4 ESD Warning

See drawing CI-35152-XP or CI-35152-IS for ESD Warnings.

Section 2: Installation on Existing Magnetic Level Indicator (MLI)

2.1 Tools Required:

Pliers/Adjustable Wrench

#2 Phillips Screwdriver (24V terminals)

2mm Allen Key (enclosure set screw)

5/32 Allen Key (chamber brackets)

5/16 Nut Driver or equivalent tool (hose clamp)

2.2 Vibration Kit (if Required)

A special mounting kit with material to reduce the effects of vibration on the electronics is available. If

you did not request this kit at time of purchase but feel it is needed, contact the factory for assistance.

See section 2.5 for Installation Procedure.

2.3 Temperature/Insulation Safeguards

Sensor shall always be installed on the outside of an Insulation Blanket if one is present. Centerline of

transmitter probe to be no more than 0.75 inches (19 mm) from outside surface of chamber.

If an existing gage has cryogenic insulation in place, transmitter must be installed in a thermowell, or

other device, to protect unit from ice build-up which can damage transmitter. Factory supplied

thermowell is available –consult Bulletin or Application Sheet for more information.

Existing Heat Tracing Installation

•Electrical and Steam Heat trace must be at least 1” from Magnetostrictive sensor and/or

electronics housing.

•Refer to maximum ambient temperature rating in section 6.3.

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

6

2.4 General Preparation Tips

General Sensor Handling “Tips”:

•Do not bend sensor tubing.

•Do not strap/attach other devices to the transmitter probe or electronics enclosure.

•Only use factory provided mounting brackets to secure transmitter to chamber.

Site Preparation

•Verify no magnetic devices nearby (see heat trace note, section 2.3).

•Verify no carbon steel or magnetic material is near sensor probe. (Should not be within 5

inches [127mm] of either transmitter or Magnetic Level Gage Column.)

oSome “stainless” clamps are low-grade stainless steel and are magnetic. Be careful

only to use non-magnetic stainless-steel clamps.

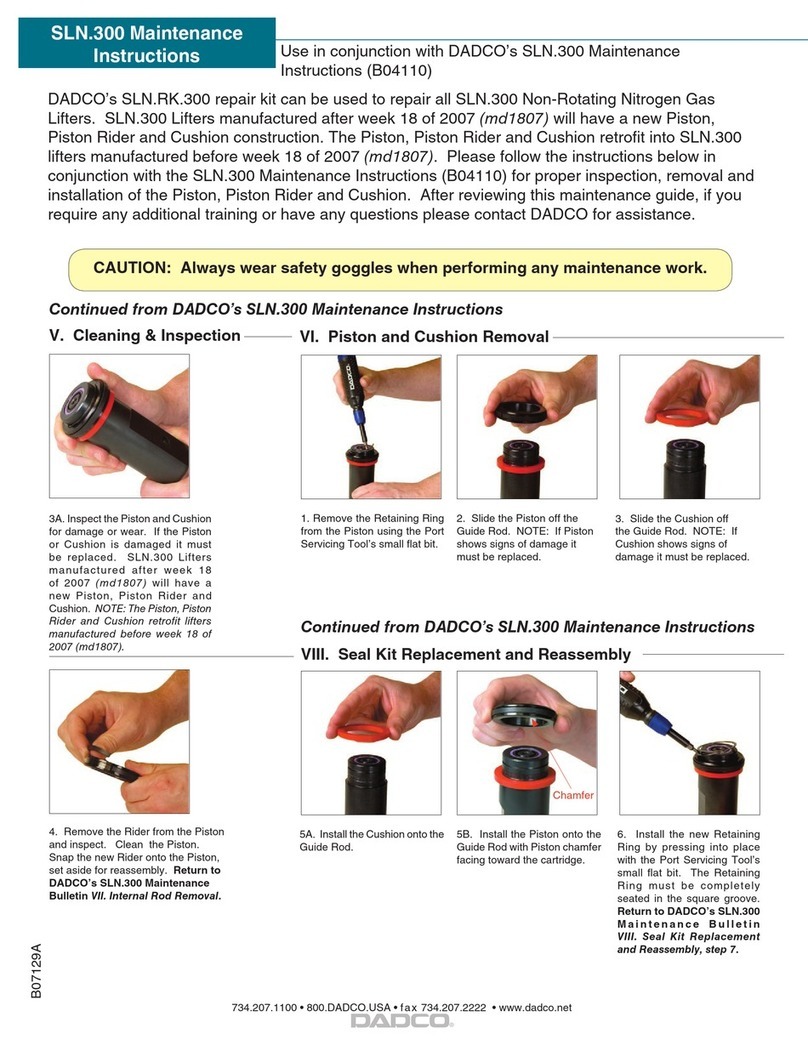

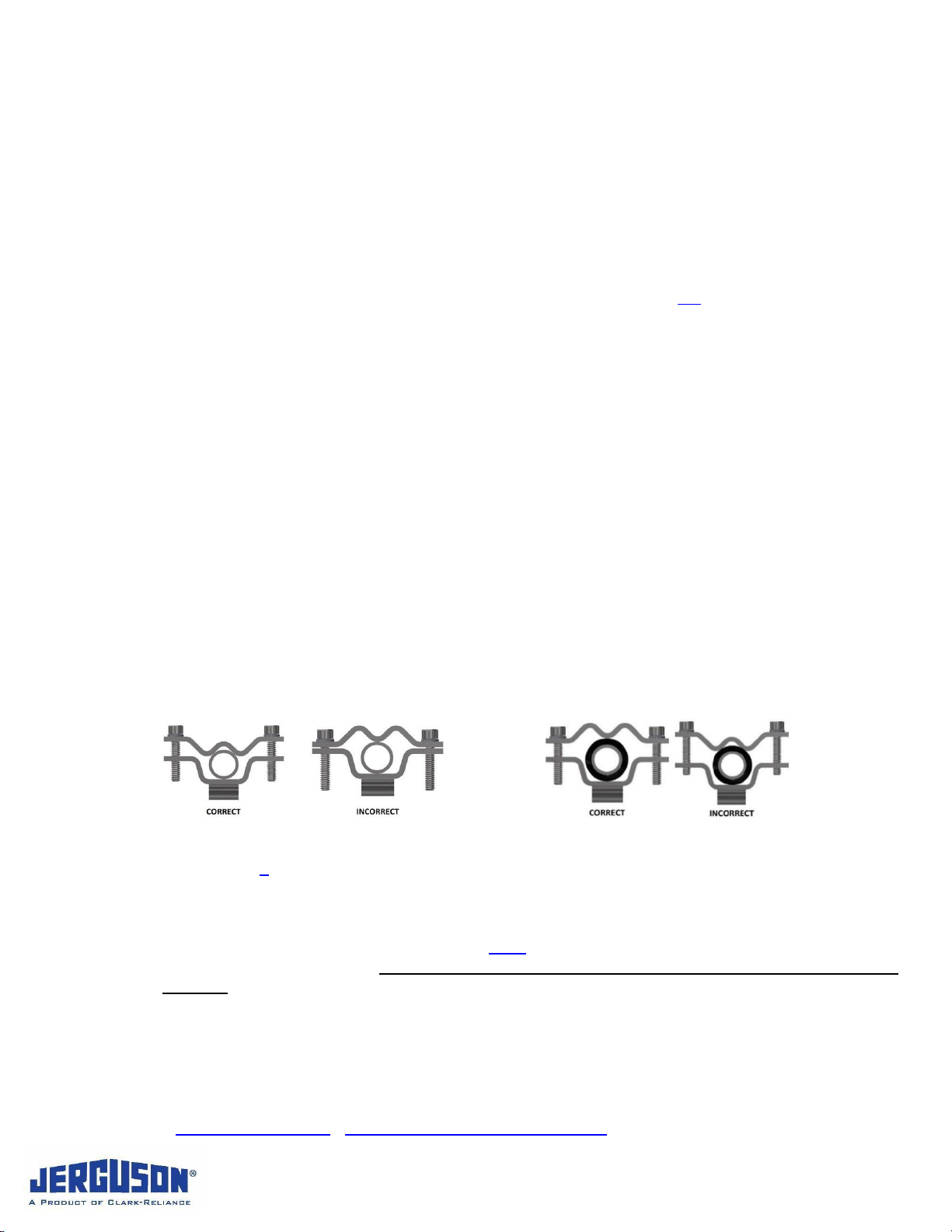

2.5 Installation Procedure

1. Secure the brackets to the chamber using the supplied hardware kits. Place (1) bracket as close

to the tee as possible. Place (1) bracket as close to the end of sensor as possible. Evenly space

the rest of the supplied mounting brackets approximately (18) inches [457 mm] along the length of

the sensor in between the top and bottom brackets. Do not exceed (24) inches [610 mm] bracket

spacing.

2. Align the '4mA' and '20mA' level range markings on the sensor tube with the center of process

connections or limits of measuring range. Once sensor is properly aligned, tighten the bracket

screws using the 5/32" Nut Driver or equivalent tool. Assistance may be necessary to hold the

sensor while tightening the screws. To test if the sensor is properly tightened, pull up or down on

the electronics housing. The sensor should not move.

Non-Vibration Mounting Bracket Orientation: Vibration Mounting Bracket Orientation:

3. See Section 3for wiring instructions.

4. Module (Display) Rotation

If you decide to flip the transmitter (section 4.2.7) you will need to remove the module and rotate it

180° to the desired position. The unit must be disconnected electrically before removing the

module. Remove the cover to access the module. Utilize the pull handle to gently rock and

remove the entire module. Once removed, align to desired viewing orientation and line-up the

connectors with the receptacles in the Base PCB. Gently press in on the board using the washers

that hold the pull handle. Reconnect to the power supply; boot screen will appear on the display,

signaling the module is fully installed. Replace cover.

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

7

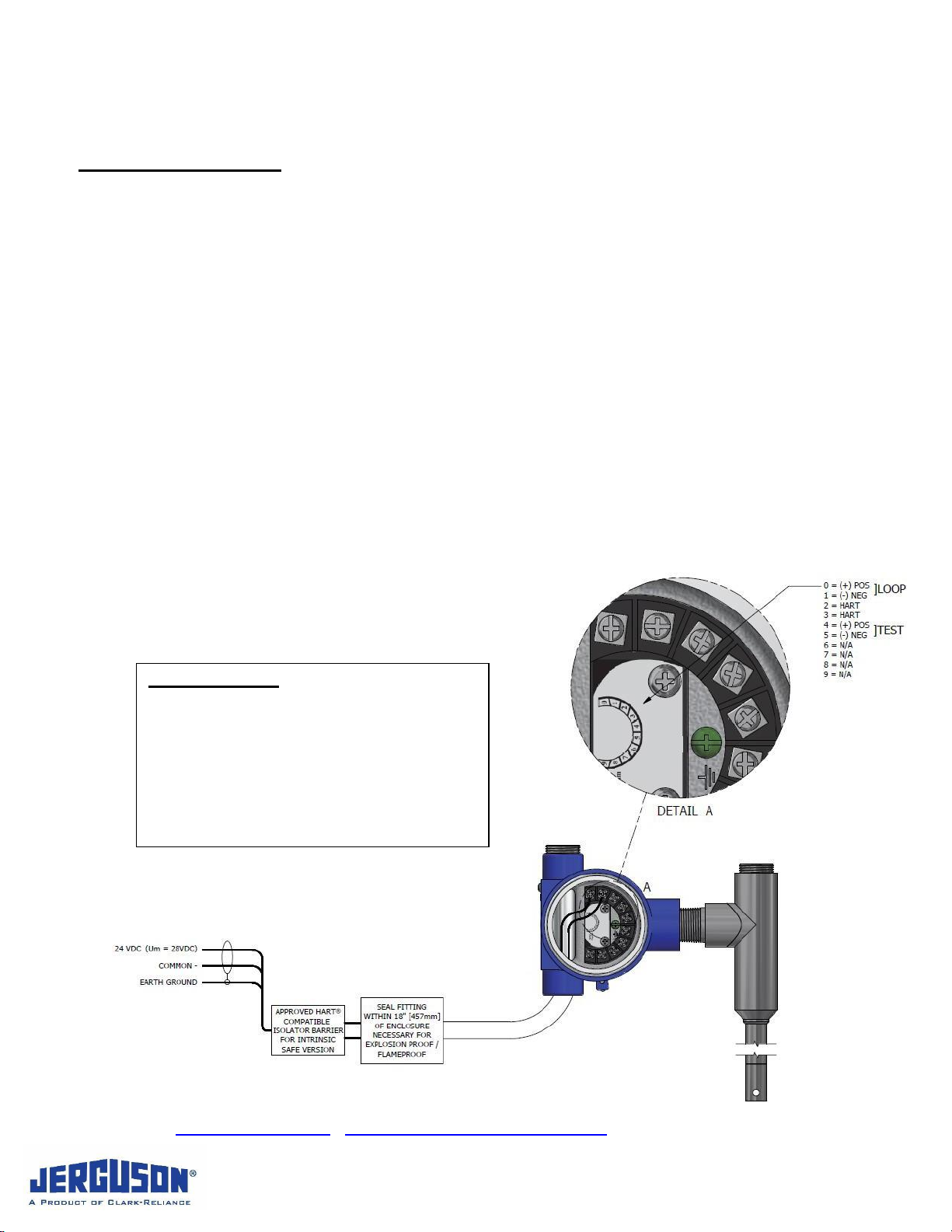

Section 3: Wiring

3.1 Hazardous Location Safety:

See drawing CI-35152-XP or CI-35152-IS for all Hazardous Location installation safety information.

3.2 Proper Grounding:

Conduit is not an acceptable form of grounding.

Proper grounding is required in hazardous locations to prevent damage to the equipment and the

following:

•electrical faults to ground

•accumulation of electrostatic charges

•atmospheric discharges

The JMT is supplied with both an external and internal earth grounding screw. Either of these

screws can be used to properly ground the device.

3.3 Recommended Loop Wiring (Diagram)

BEST PRACTICE:

All JMT Transmitters come with the UPPER

housing conduit entry plugged as shown in

image below. (Second entry is plugged with

temporary plastic NPT plug.) It is best practice

to connect conduit via lower available entry to

prevent water ingress. In the even unit is

flipped in field, Jerguson recommends

switching the plug to follow this orientation.

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

8

Section 4: Configuration

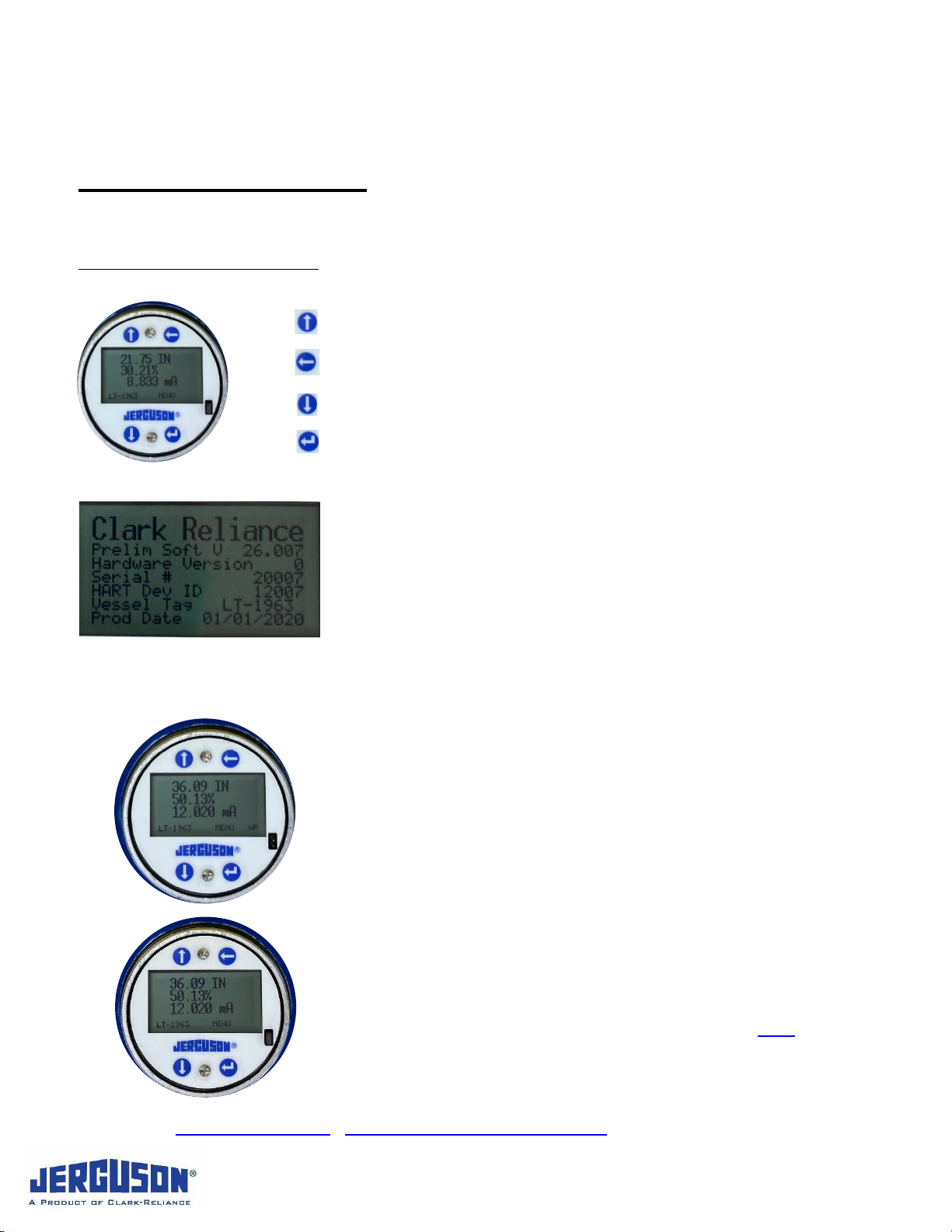

4.1 Operation Screen

Push Button System Navigation

Up will advance the cursor up in the menu system.

Back will advance to the previous digit in a menu.

Down will advance the cursor down in the menu system.

Enter will select a menu option or advance to the next digit when

entering a value.

4.1.1 Boot-Up / Welcome Screen

Software Version: Ex.: V 29.000

Hardware Version: Ex.: 0

Serial # Ex.: 456789-01A

Hart Dev ID Ex.: 1001

Vessel Tag (if setup) Ex.: LT-1963

Production Date Ex.: 04/14/2021

4.1.2 Standard Operating Screen

Engineering Units

Inches, Millimeter, etc. (Selected in User Installation)

Percent Output

Defined as % of Level 4-20 mA

The % Output given will correspond with the mA output

current value between 4 and 20 mA

mA Output

Display of 4-20 mA analog output

Vessel Tag (if value is set –see User Installation)

WP If Write Protect Jumper is removed, bottom right will

display “WP” notification. See section 4.1.4.

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

9

4.1.3 Standard Operating Screen –DUAL FLOAT

If you have purchased a JMT with the dual float option enabled,

it will be done so by default, and cannot be changed without

factory assistance. The unit must have two (2) floats to function

properly and will flash “LOST SIGNAL” if second float is not

installed.

The Standard Operation Screen in dual float mode will display

both the media level and the interface level, with the % of full

scale and output current of the selected output in Rerange

menu in section 4.2.6.

4.1.4 Write Protect Jumper

Jumper in place (shown at right)

Jumper removed (shown at left) and Write Protect enabled

Menu is accessible, but will all non-information selections will

display

Jumper Removed

Protection Enabled

on screen and revert back to Standard Operating Screen

4.1.5 Waveform View Pressing Back from the Standard Operating Screen will

display a graph of the signal measured by the instrument. If a

float is detected it will center on the position of that float,

showing the lowest and highest value on the graph, in units

selected in user installation. This will always be in terms of

distance from the tee/enclosure and not the reported level.

Pressing Up and Down will move the graph further and closer

to 0.0, respectively. The graph will always be scaled from 0-

2.5V, with a horizontal dotted line indicating the trigger level

(ADC Max Voltage). The detected signal must be above trigger

level for the electronics to treat a reading as a valid level signal.

A detected float will be marked with a pair of solid vertical lines, indicating the time at which the signal went

above, and then fell back below the trigger level. If a signal is detected that passes the trigger level, but is

filtered out, a pair of dotted lines will be shown on that part of the signal. The number of signals detected will

be shown in the upper right corner marked with a “Sig”. If no float is detected, the solid vertical lines of where

the float was detected previously will be displayed.

Press Back again to exit this feature.

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

10

4.1.6 Signal Lost Screen

In the event the instrument is no longer detecting a magnetic field

from the float (in single level or in dual level), “Signal Lost” will flash

between black and white on the display. The output current is set

to the NAMUR- 43 standard of either 3.5 mA, or 21 mA, based on

user selection.

See Alarms in section 4.2.10 for alarm options.

See section 5for troubleshooting lost signal.

4.2 Menu Screens

4.2.1 Accessing the Menu

Press Enter under the word “MENU” as shown here.

Push Button System Navigation

Enter will select a menu option or advance to the next digit when entering a

value.

Up will advance the cursor up in the menu system.

Down will advance the cursor down in the menu system.

Back will advance to the previous digit in a menu. If in the Standard Operation

Screen or Signal Lost Screen it will display the Sensor Output Graph of

channel 3. (See Waveform View, section 4.1.5)

Entering Values

The total number of available leading digits and decimal places will be shown for each properties value. The

cursor will begin in the ones place, indicated by the underline of the value.

For example: 001.00

When entering a property, the value displayed is the currently used value. Pressing on the Up button will

increase this value by 1. If at 9, this would increase to 10.

For example: 009.00 -> 010.00.

Pressing on the Down button will decrease this value by 1. By pressing the Back button, the cursor will

move to the next highest place value, the tens place. If cursor is in the tens place pressing back will move to

the hundreds. For example, 010.00 => 010.00. Pressing Enter will move the cursor to the next lowest place

value, from the tens place to the ones, or ones to Tenths.

For example: 001.00 => 001.00.

If in the tenths place, pressing Down will decrease the total value by 0.1.

For example: 100.0 => 099.9

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

11

Once an acceptable value has been entered, press Enter until the cursor is on the last available place. Press

Enter again and the next property in that menu subsystem will be displayed. If too large or too small a value

is entered for a parameter, it will be rejected with the maximum or minimum value in violation displayed.

Menu System Navigation

The Menu is accessed by pressing the Enter button. Details of each submenu are given in subsequent

sections.

Once you have entered a submenu it is necessary to progress through the entire submenu before exiting it. It

is not possible to use the Back button to exit a Menu.

If you leave the menu system open for 2 minutes with no inputs, it will automatically exit to the Standard

Operating Screen.

WARNING

While in the Menu System HART commands will be disabled.

4.2.2 Menu (First Screen)

Device Info

User Installation

Rerange

Flip Transmitter

One Point Calibration

Calibration

Alarms

4.2.3 Menu (Second Screen)

Filters

Reset Factory Configuration

Factory Configuration (Factory Password Protected)

Diagnostics

Exit Menu

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

12

4.2.4 Device Info

This will display the device information and configuration data, as well as whether the calibration has been

modified since being shipped from the factory.

Boot/Welcome Screen

Software Version

Hardware Version

Serial#

HART ID

Vessel Tag (if entered)

Production Date

Instrument Config

Single/Dual Float

Engineering Units Selected

Sensor Length

4mA setting (LRV)

20mA setting (URV)

Gain %

Trigger V (Voltage)

Min Signal Width

Level Offset (if entered)

Top/Bottom Mount

Calibration Status (Sensor/Loop)

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

13

4.2.5 User Installation Level Units

The JMT will come preprogrammed to the desired user

installation. If however it is desired to change any of these

settings, they are done so through this menu.

Level Units

Selection between units, if this is changes it will propagate, and

show the units across the values to be entered for all properties.

Inches XXX.XX (Two Decimal Places)

Feet XX.XXX (Three Decimal Places)

Millimeters XXXXXX (No Decimal Place)

Centimeters XX.X (One Decimal Place)

Meters X.XXX (Three Decimal Places)

1/16 Of a FootXXXX.XX (Two Decimal Places)

Use Up and Down to select desired Engineering Units to be

displayed. Then press Enter to move to next screen.

Level Offset

This is a user value for if they have a need to report a level

offset from the measured level. Typically, this is the distance

from the lowest point the sensor can measure, to the bottom of

the tank, or any zero-reference point lower than end of the

Magnetostrictive sensing element. Use Up/Down (or Back to

change position) and Enter to move to next screen.

Note: Offset cannot be Sensor Length.

Vessel Tag

This is an 8-character tag that can be used to name the

instrument for the operator. If set, this tag will be displayed on

the Main Operating Screen. This is a distinct tag from the

HART tag, which can only be set via HART.

Long press of the Up or Down buttons scrolls quickly through

the alpha-numeric selection. Enter sets each place’s value.

Once tag is set, press Enter as needed to close out the screen,

Note that the vessel tag will only be displayed if the first

character is changed.

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

14

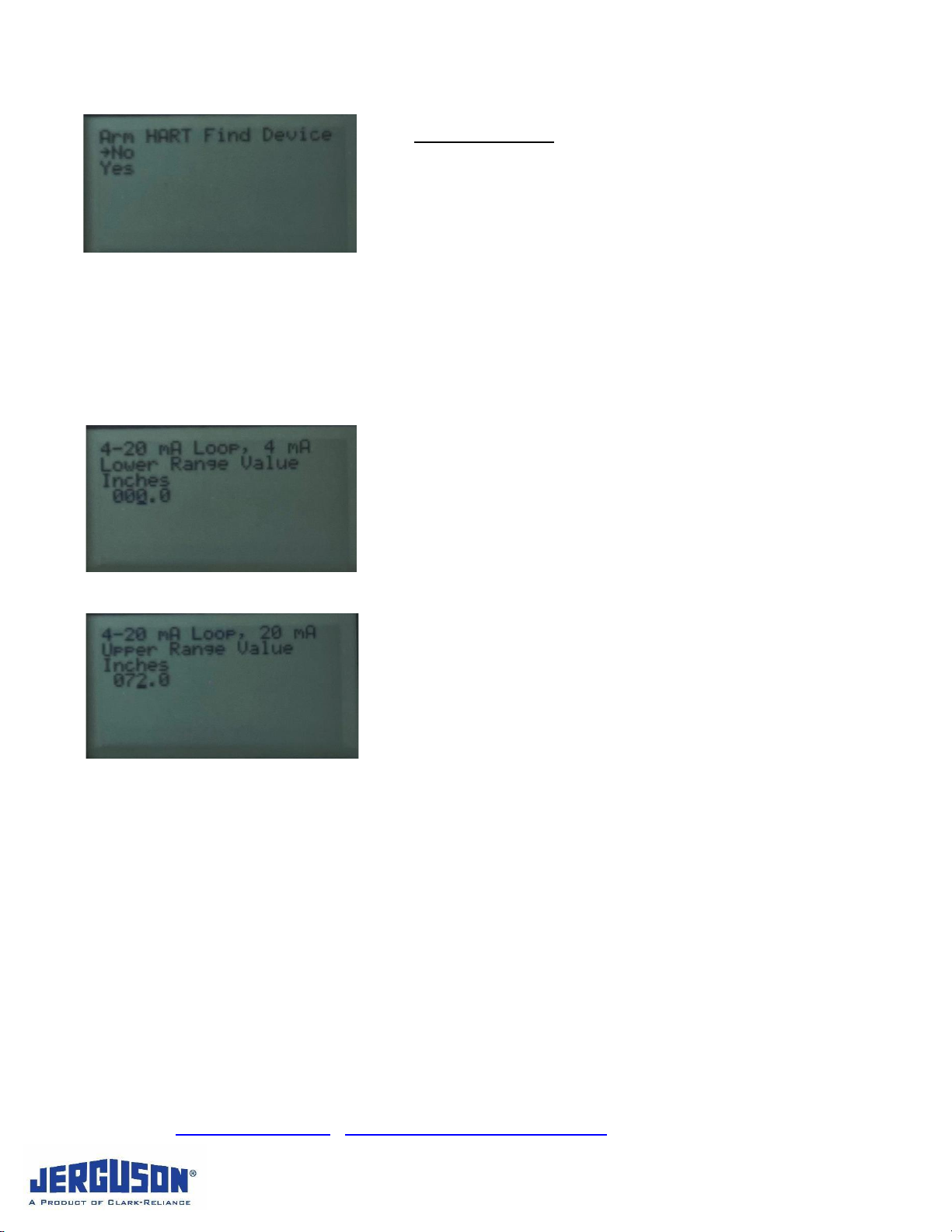

Arm HART Device

Standard HART Command to set bit to be “found” by

MASTER/HOST.

4.2.6 Rerange

NOTE: If Dual Float setup, first screen will be choice between Interface and Media Level. Subsequent

screens are the same.

Enter the value desired for 4mA reading. Note this should be

measured from the dead band set at the factory and marked on

the sensor. Typically, the Zero is 000.0 for measuring the full

(default) span.

A transmitter rerange can be done to change the measured level

for which the output will be 4 and 20 mA. It will not affect the

level measurement reported in engineering units selected

(inches, millimeters, etc.), just the current and percentage

output. The units for both will be based on those set in User

Installation.

Enter the “span” for “full” value. Typically, this is equal to the

measuring range as ordered.

Reminder: Reranging the 4mA/20mA will change the % and mA

readings on the display, but NOT the engineering units. For example,

on a 96” max measuring range unit, moving the 0” to 24” and the

full/span from 96” to 84” would have the following effect: from 0” to 24”,

the engineering units would rise as the float does, but the mA output

would be 3.8mA (empty saturation) with a corresponding negative %.

At 24”, the mA output and % would be 4mA and 0%, respectively, and

begin to rise linearly until 20mA/100% at 84”. Above 84”, the mA output

would rise to full saturation 20.5mA with a corresponding 100+% value.

(Exact negative and 100+% driven by length of span and differ by unit.)

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

15

4.2.7 Flip Transmitter

Select Top or Bottom Mount (Head Location)

CAUTION:

For accurate measurement, it is recommended you perform a

Trim function as seen in section 4.2.8.

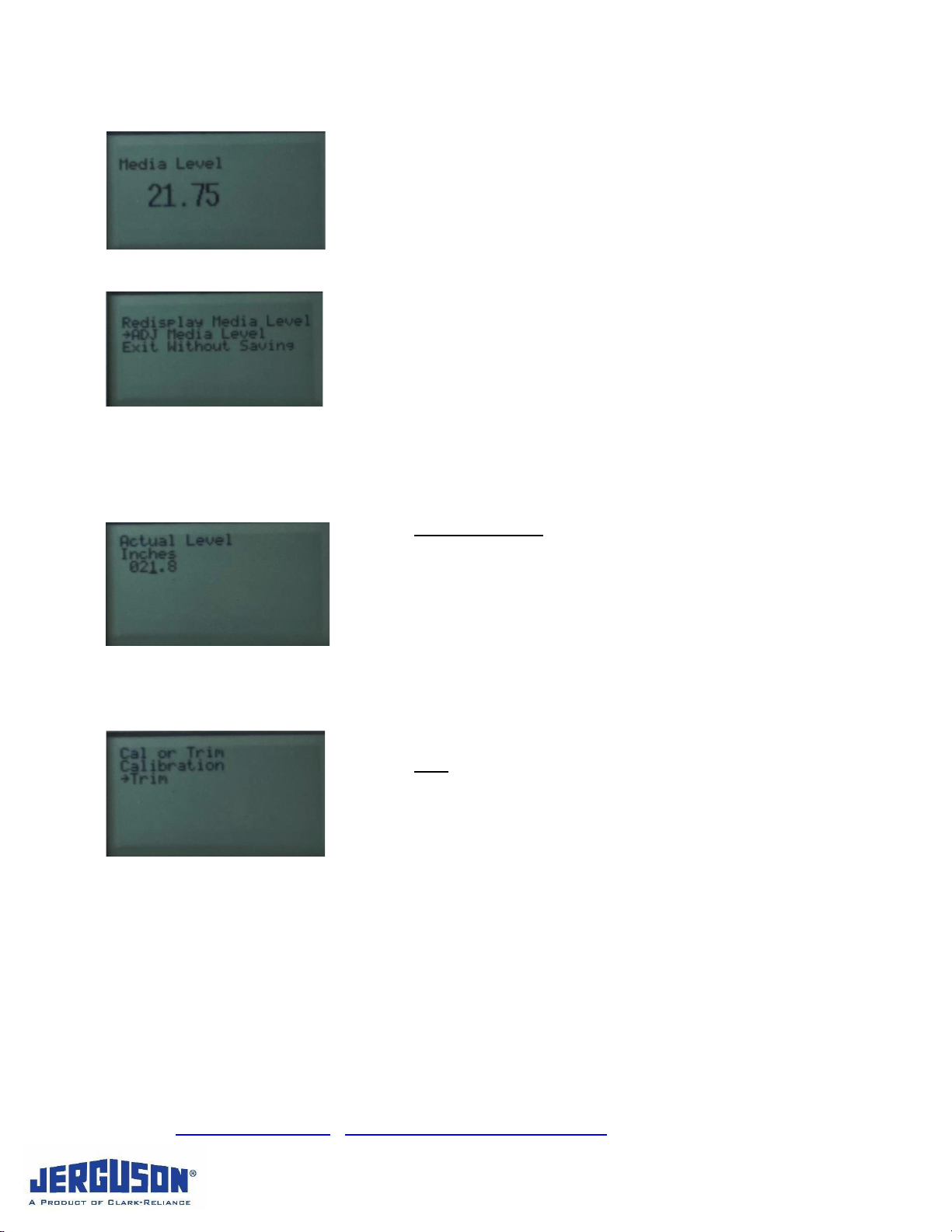

4.2.8 One Point Calibration

Note: The JMT is designed such that it should never require recalibration. The below actions are to

be utilized for very specific reasons.

Two forms of One Point Calibration are available. Calibration is

an emergency procedure to be used only if moving the

instrument electronics/module between two installations. See

Calibration/Level Sensor 2Pt Cal for more accurate calibration.

Trim is used either after performing Flip Transmitter, or if the

entire instrument and probe is being moved from one installation

to another.

See section 5for Troubleshooting.

Calibration

This is the overall length of the sensor. Only used if Calibration

has been selected.

4-20 mA Loop, 4mA lower Range Value

This will set the measured level at which the output is

4mA. It will be done in the units set in User Installation.

4-20 mA Loop, 20mA upper range value

This will set the measured level at which the output in

20mA. The maximum value for this is the Sensor Length

parameter.

Perform Float Position Calibration

Note: this is same as Trim command from upper menu.

You will be prompted to decide if this step is necessary; No

reverts back to menu.

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

16

If you select Yes, the currently measured level will be displayed,

After a few seconds, the user will be prompted to Redisplay

Media Level, ADJ (Adjust) Media Level, or Exit Without

Saving.

If you agree with the output, simply Exit Without Saving. To

calibrate the output to a different measurement, select ADJ

Media Level.

ADJ Media Level

Unit will show current media level. Use buttons to change value

to desired reading. Enter value. Upon completion, you will be

reverted back to Main Menu.

Trim

This function is required flipping the transmitter or is moving the

entire unit from one installation (chamber) to another. See

Perform Float Calibration above.

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

17

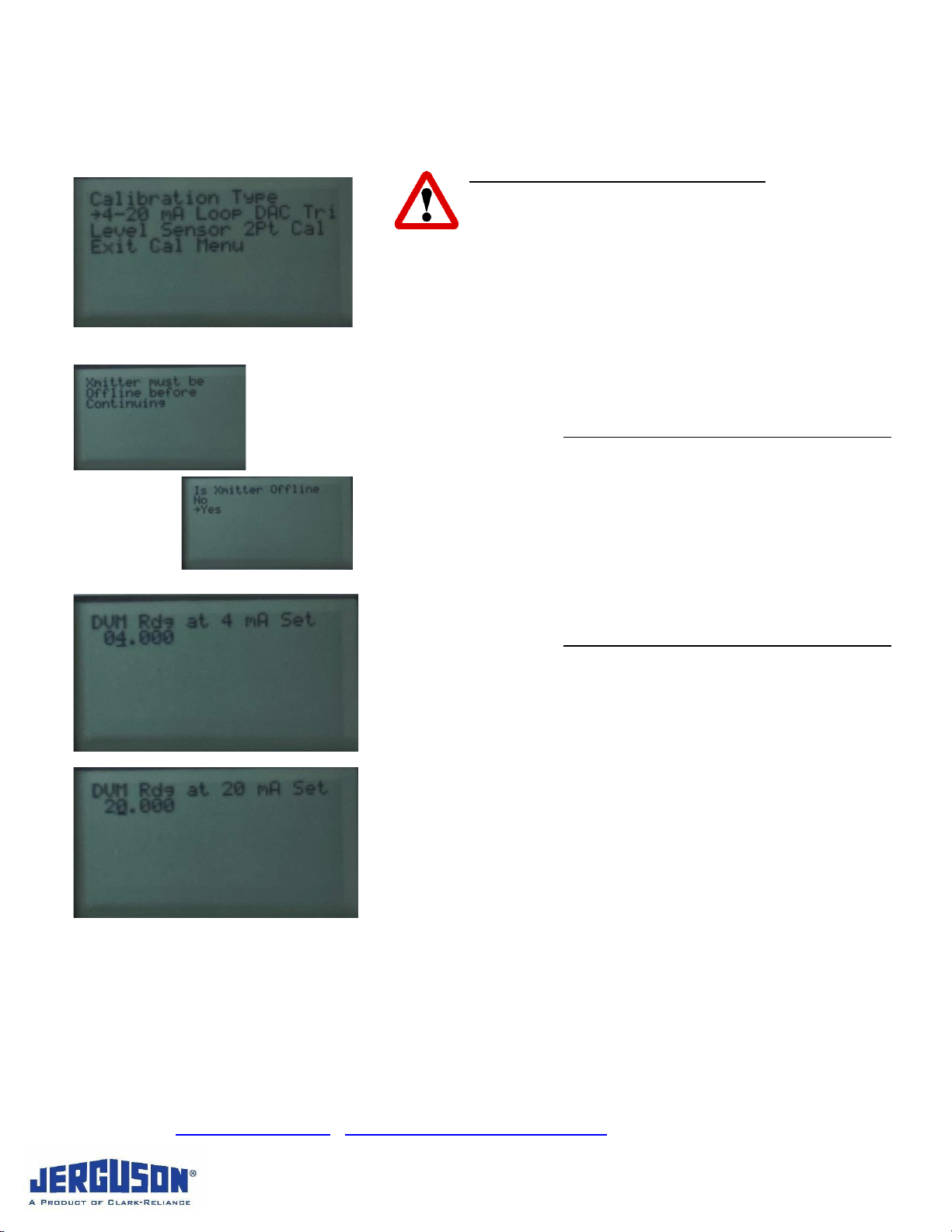

4.2.9 Calibration

DAC Trim (Digital to Analog Converter)

The purpose of the DAC trim is to calibrate the current

output of the transmitter. This process should only be

done with a NIST (National Instrument of Standard and

Technology) traceable multimeter, AND the transmitter must be

offline from any control processes.

First connect your NIST Traceable Multimeter in series with the

Loop power on the Negative side. Select 4-20 mA Loop DAC

Trim.

Press Enter and the transmitter output will go to 4mA, and

prompt to enter the measured current output on the multimeter.

NOTE: These should be very subtle changes, ex 4.000 may

read 4.004 (requiring 4.004 to be entered)

Large changes would indicate a problem with set up or even

possible damage to the JMT

Once complete, the transmitter output will go to 20mA, and

prompt to enter the measured current output on the multimeter.

Once complete, it will revert back to the Calibration menu.

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

18

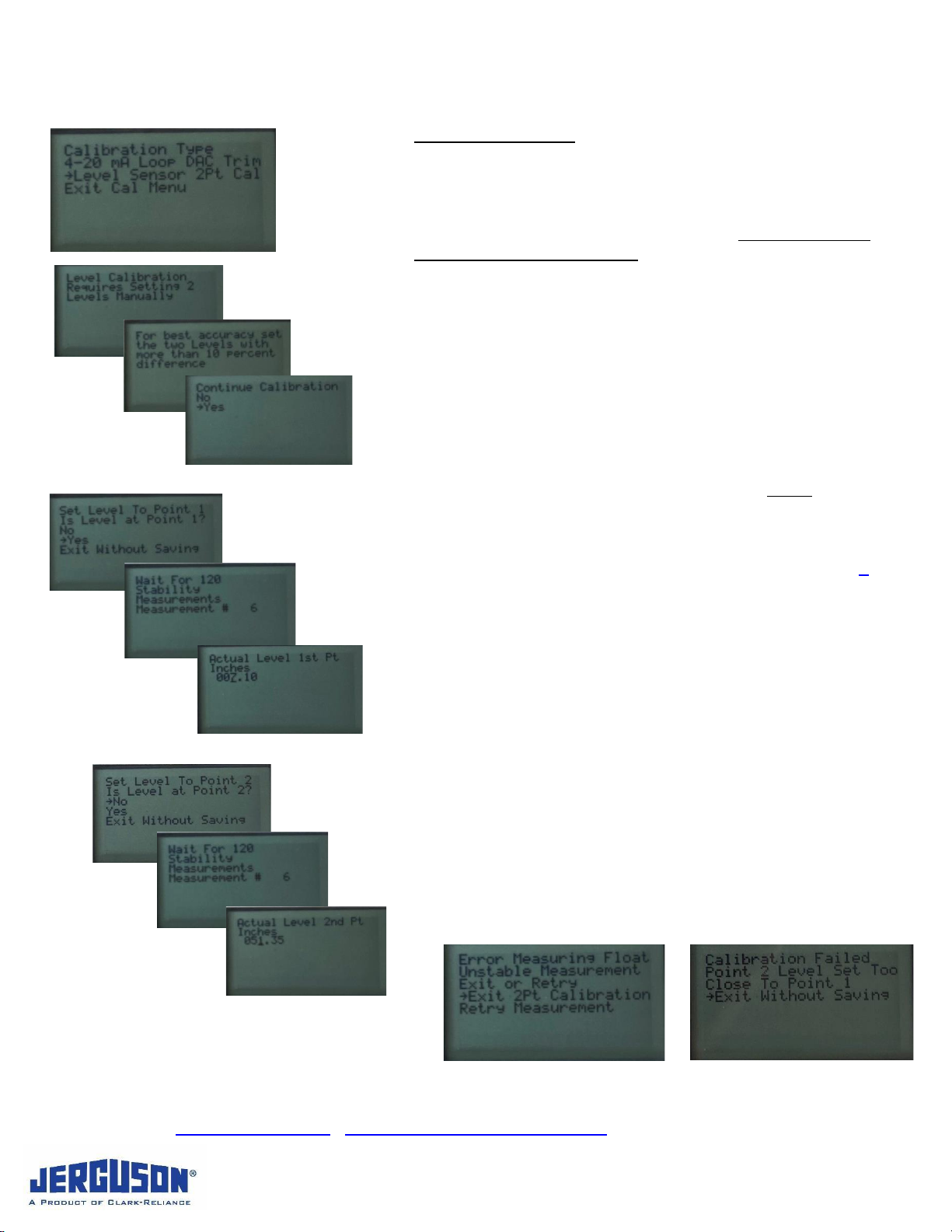

Level Sensor 2Pt Cal

The instrument will come calibrated from the factory and should

not require a two-point calibration. However, it may become

necessary if the instrument is installed in an area with a very

high ambient air temperature at the probe. This requires the

ability to move the float level.

A Two Point Calibration may be accessed through the

Calibration Menu. You will be prompted to verify that the

transmitter is offline, and that the process is most accurate if the

two points used are greater than 10% of the probe length apart.

The two points can go in order from higher to lower, or lower to

higher levels.

It will ask if you want to continue. No reverts to the Calibration

menu. Yes will have you set the float at point #1. You will need

to know the position of the float and it must be stable. When the

float is at point #1 and stable, press Yes. (120) Measurements

will be taken to provide the highest possible accuracy

calibration. If a stable signal is not detected, you will be

prompted to set the Gain and Trigger Level. (See section 5

Troubleshooting)

If a stable signal is detected, you will be prompted to enter the

actual level of the float.

Do so and then move the float to point #2 and repeat the

process. Remember it must be at least 10% the Overall Length

of the sensor different from point #1. If the points are too close,

the calibration will fail.

After entering the float position at the second point, a verification

process will begin. If the values are too close together the

calibration will fail. If the verification of the calibration is correct,

you may exit the process finishing calibration. This verification

process is used to prevent incorrect calibrations from entering

the instrument. If not you may re-attempt verification, or redo the

calibration.

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

19

4.2.10 Alarms

There are four possible alarm conditions available in the event

that the float is not detected.

3.5 mA –Current output will go to 3.5 mA if a float is not

detected.

21.0 mA –Current output will go to 21.0 mA if a float is

not detected.

Hold last then 3.5 mA –Current output will go to 3.5 mA

if a float is not detected after waiting a user specified

number of second (Up to 1000 seconds).

Hold last then 21.0 mA –Current output will go to 21.0

mA if a float is not detected after waiting a user specified

number of seconds (Up to 1000 seconds).

4.2.11 Filters

Several filters are automatically used by the JMT to prevent erroneous signal measurement. These filters

may be adjusted as described in the Measurement Troubleshooting section in Section 5

Troubleshooting. There is no need to do so under normal operation.

Rate of Change Filter

The Rate of Change Filter is designed to remove random noise

the sensor may detect from vibrations or electromagnetic

interference. The operating principle is that there is a maximum

speed at which the float can move, meaning the measured level

can only change so much between each measurement. Each

measurement is compared to the one before it, and if a signal is

detected outside what this filter would allow it is ignored,

allowing the true signal from the float to be detected.

The Rate of Change Filter is set with both a distance

measurement, and time requirement.

Installation, Operation, & Maintenance Instructions

IOM J500.35

2021.04

JMT

www.Jerguson.com ● JergusonApp@clark-reliance.com ● +1.440.572.1500

20

Smart Smoothing

The Smart Smoothing Filter is designed to smooth out

variations in the measured level from the float rotating or

leaning in the chamber. It works by averaging the

previous measurements over the specified # of seconds

and calculating that as the measured level. The factory

default setting of 3 seconds.

If the float were to move extremely rapidly (for example

by hand) this would show some delay in updating

measured level.

Media Level Dampening

Damping is available on the Current Output, this will

damp the change in output current, not in the actual

measurements.

Pulse Width, Gain and Trigger Level Filter

The pulse width filter is designed to remove signals

detected by the sensor that do not match the signature of

the float of the instrument. A float will provide a large,

long signal, while something like spurious electrical noise

will provide a short signal. The pulse width filter

calculates the amount of time the signal is above the

specified trigger voltage and rejects it if it is too short.

This, in combination with the Rate of Change Filter

makes it extremely difficult for any electromagnetic noise

to affect the instrument.

Three channels will be available. Channel 1 and Channel

2 are the output of the two individual crystals in sensor.

Channel 3 is their combined input which is what is used

by the level measurement instrument.

Table of contents

Other Jerguson Industrial Equipment manuals