1 of 3

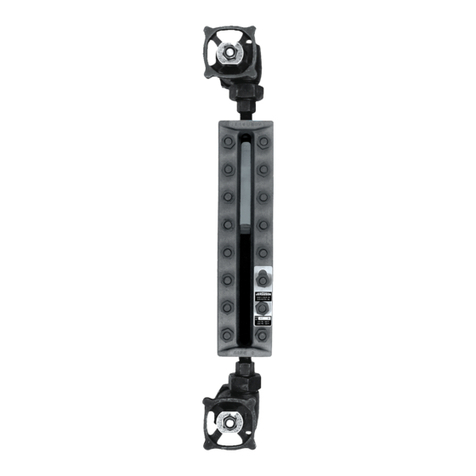

Specialists in Liquid Level Indication

STORAGE and HANDLING

The Jerguson LED Explosion Proof Illuminator

meets or exceeds all applicable specifications when

shipped from the factory.

All units should be inspected upon receipt to ensure

that no damage has been incurred during transit. If

there has been damage, a claim should be filed with

the carrier immediately. Unit should be stored in an

area protected from the elements and corrosive

fumes, in a secure manner where they can neither

fall, nor be struck by other objects. Care should be

taken to protect the window and the end connections

from damage. Avoid placing any objects directly

on the light at any time.

COMPONENTS

There are three main components that make up the

LED illuminator: the light strip, the power supply,

and the cable connecting these two main pieces.

The cable may have more than one piece depending

on the required distance between the illuminator and

the power supply. Questions regarding acceptable

applications should be directed to The Clark-

Reliance Corporation.

INSTALLATION

CAUTION: All lights are tagged with the

service conditions for that particular unit. These

specifications are located on the Jerguson tag on

the power supply housing, and are contained in

the “Specifications” section of this manual. Do

not use or refer to specifications listed on red

label on the power supply housing. They are

specifications for generic use. Review the ratings

prior to installation and again prior to start-up,

to ensure proper operation in the installed

environment. Should there be any doubt as to

the applicability of a unit for the installed

environment, consult the factory before placing

the unit into service.

Note: All installation steps should be

performed by a qualified technician and should

be executed in accordance with all applicable

national and local codes.

The light and power supply should be checked to

ensure that they contain no foreign matter, and that

the end connections are clean, undamaged, and in

line with existing conduit.

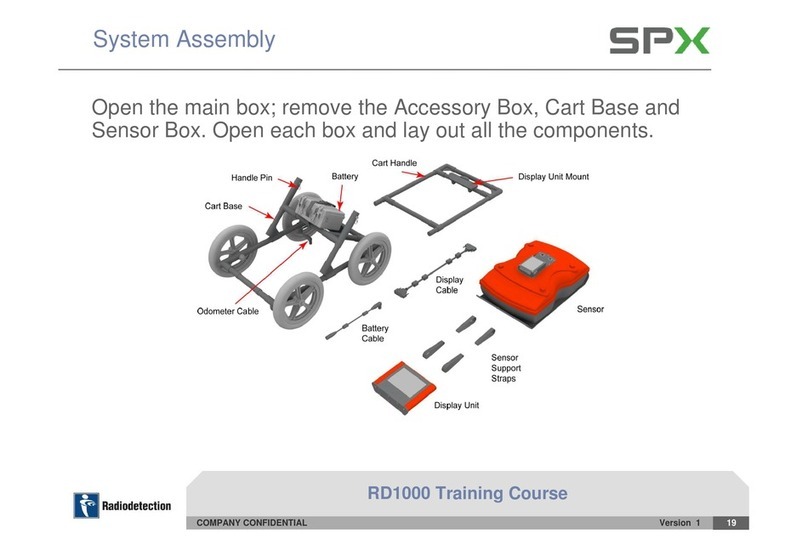

Step by step instructions:

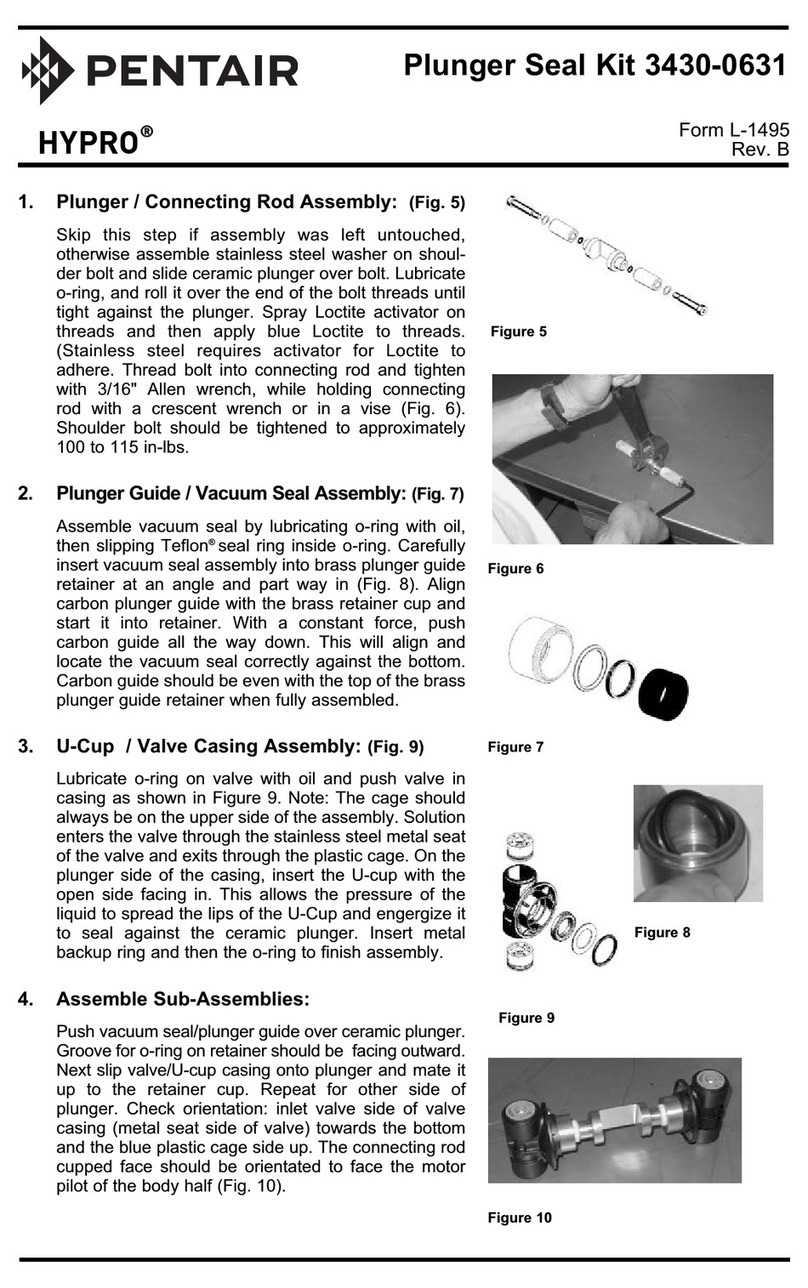

1) Loosen the set screws on the mounting

brackets and align the cut out on the

mounting bracket so that the distance

between the two mounting brackets line up

with the desired bolt heads on the liquid level

gage.(See Figure 1)

2) Place one side of both mounting brackets

under one side of the gage cover and then

using a rolling motion, snap the other two

halves of the mounting bracket to the other

side of the gage.(See Figure 1)

3) Open the cover of the power supply housing.

Insert the AC Line wires into the housing and

connect to the “AC IN” terminal block. A

ground screw is located inside the enclosure

if required. CAUTION: The DC output is

pre-wired. If this connection is removed

during installation, reconnect the “AC IN”

and “DC OUT” to the proper positions.

Failure to do so will result in permanent

damage to the power supply.

4) IMPORTANT: The customer must have a

“sealing fitting” in the conduit supplying

power to the light’s power supply within

18” of the power supply.

LUMASTAR™ EPL-100

INSTALLATION, OPERATING &

MAINTENANCE

INSTRUCTIONS

Section: J500

Bulletin: J500.32

Date: 07-12-06

Supersedes: 02-03-05

NORTHEAST CONTROLS INCORPORATED

TEL: 201-327-7660 | FAX: 201-327-3242

NORTHEAST CONTROLS INCORPORATED

TEL: 201-327-7660 | FAX: 201-327-3242