DANGER

!!

THIS PRODUCT CAN BE DANGEROUS IF NOT USED PROPERLY! Always wear

appropriate Personal Protective Equipment (PPE). Detailed PPE information can be found

at: www.fsesgsafety.com and clicking on the JETSTREAM name or by referring to the

yellow JETSTREAM SAFETY WARNING pamphlet (PI-082).

The following Quick-Start Guide is intended to provide the customer with an

expedient reference for DrillJet installation and operation. It does not replace the

complete product instructions (PI-180).

This product is sold with the understanding that the purchaser agrees to

thoroughly train all operators and maintenance personnel in the correct and

safe installation, operation, and maintenance of the product and to provide

adequate supervision of personnel at all times. JETSTREAM urges customers

to make complete instructions available to all personnel and ensure they are

read thoroughly before installing, connecting or using the DrillJet. Retain these

instructions for future reference. If this product is resold or otherwise conveyed,

the purchaser must pass on these instructions to the new user. If any questions

remain, or to request additional copies, call JETSTREAM at (800) 231-8192 or

(832) 590-1300.

Read the yellow JETSTREAM SAFETY WARNING pamphlet (PI-082) included with

the shipment of the product.

CONNECTING DRILLJET

Prior to the start of any job, make sure only high pressure rated ttings and

hoses are used in the waterblasting system.

Prior to installing the DrillJet onto the hose, ush the system to clear any debris.

BSPP CONNECTION

1. BSPP at seal connections require a copper crush washer between the male

and female connectors.

2. Seat copper crush washer in female BSPP connection on mandrel.

3. Apply anti-seize compound to the mating threads of mating hose end.

4. Install the DrillJet by using an appropriate open-ended wrench on ats found

on the body and tighten until rmly snug (20 ft-lbs. max).

STRAIGHT THREAD CONNECTION (M7 and MEDIUM PRESSURE (MP))

1. Apply anti-seize compound to male threads of the connection.

NOTE: DO NOT use Teon tape.

2. Install the DrillJet by using an appropriate open-ended wrench on ats found

on the body and tighten until rnly snug.

NOTE: DO NOT OVERTIGHTEN; damage to coned sealing surface could result.

FOR ALL NPT CONNECTIONS

1. Apply 3-4 wraps of Teon thread sealant tape to the available male threads of

the connection.

2. Apply anti-seize compound over the sealant tape for additional protection

against galling.

3. Install the DrillJet by using an appropriate open-ended wrench on ats found

on the body and tighten 1-2 turns past hand-tight. All NPT pipe connections

should have a minimum thread engagement of (4) threads.

OPERATION

As per the WJTA-IMCA Recommended Practices, all operators shall follow the

OSHA regulations for personal protective equipment. (OSHA guidelines for

Personal Protective Equipment are available in document number 3151-12R 2004,

which can be obtained from www.osha.gov.) All operators shall be issued suitable

head protection, eye protection, hearing protection, body protection, hand and

foot protection and respiratory protection (if needed). For detailed specications

on all protections required, refer to the WJTA-IMCA ‘Recommended Practices

for the Use of High Pressure Waterjetting Equipment’ Section 6, Protective

Equipment For Personnel.

!!CAUTION

The DrillJet™ can be used at a minimum service temperature of -20°C (-4°F) and a

maximum service temperature of 115°C (240°F). Use at temperatures lower or higher

than these recommended temperatures may result in premature tool failure.

1. Start by slowly increasing pressure to 500 psi and check the entire system,

including all connections, for leaks. Increase pressure in increments,

pausing at each to inspect the system for leaks, proper rotation of tool,

temperature, and other operational anomalies. If any problems are

discovered, lower pressure back to zero and turn off source of power before

making any adjustments.

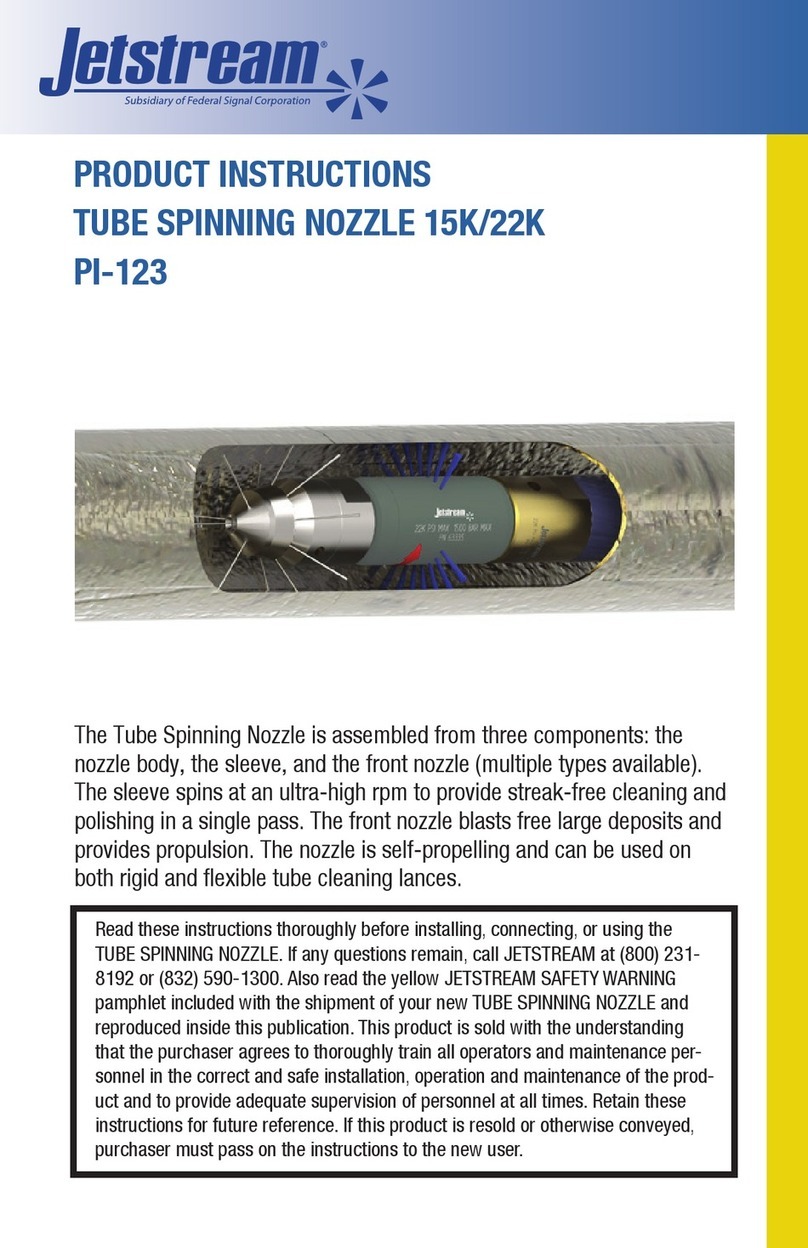

2. During operation, it is normal for water to leak out of the front of the head

from around the front nozzle (or front plug). This leak-by water comes from

the water-bearing that the tool operates on.

WARNING

!!

Remove the nozzle from service if:

a. The rotor or mandrel shows signs of cracking or other damage.

b. The wall thickness of these parts is reduced by 25% at any point.

c. The nozzles can no longer hold pressure at water flow rate for which it was sized.

NOTE: For improved reliability and longer life, it is recommended that a lter of

at least 10 microns be used on the water supply inlet. A strainer (100 mesh

minimum) must also be used in the water tank (if equipped with tank).

DANGER

!!

Failure to follow the following instructions will cause unsafe conditions, severe injury

can result.

• DO NOT operate the DrillJet above its specied pressure.

• Operator must wear ear protection due to the noise generated by the spinning

nozzle.

• NEVER stand in the plane of blasting.

• A Lance Safety Grip is recommended to minimize the risk of a live nozzle

unexpectedly exiting the tube back at the lance operator.

• At high-pressure, the water can be hot. Wear gloves and use caution to prevent

scalding.

• Place barricades with warning signs or barricade tape around work area. This

includes the waterblast unit and all high-pressure hoses.

• Operator must be outtted with proper safety apparel (refer to yellow JETSTREAM

SAFETY WARNING pamphlet). Body armor is strongly recommended.

FOR FURTHER INFORMATION SEE:

https://www.youtube.com/user/JetstreamWaterblast

and the

Jetstream Safety Manual

Jetstream of Houston LLP • 5905 Thomas Road Houston, TX 77041 www.waterblast.com • 1-832-590-1300

DRILLJET™ | QUICK START GUIDE QSG-180