Jetter JXM-HMI User manual

User Manual

JXM-HMI

We automate your success.

Jetter AG

Graeterstrasse 2

71642 Ludwigsburg

Germany

Phone

Switchboard +49 7141 2550-0

Sales +49 7141 2550-531

Technical Hotline +49 7141 2550-444

E-mail

Technical Hotline [email protected]

Sales [email protected]

Translation of the original User Manual

Revision 1.11.1

Date of issue 10/23/2019

This document has been compiled by Jetter AG with due diligence, and based on the known

state of the art. Revisions and further development of our products are not automatically

mentioned in a reviewed document. Jetter AG shall not be liable for errors in form or content,

or for missing updates, as well as for damages or disadvantages resulting from such failure.

Jetter AG Table of contents

JXM-HMI User Manual iii

Table of contents

1 Introduction .....................................................................................................................................5

1.1 Information on this document .................................................................................................. 5

1.2 Typographical conventions......................................................................................................5

2 Safety ...............................................................................................................................................6

2.1 General information.................................................................................................................6

2.2 Warnings used in this document ............................................................................................. 6

2.3 Usage other than intended ...................................................................................................... 6

3 Product description ........................................................................................................................7

3.1 Features ..................................................................................................................................7

3.2 Nameplate ...............................................................................................................................7

4 Mechanical installation...................................................................................................................8

4.1 Mounting in combination with a JVM-104................................................................................8

4.1.1 Requirements for the installation location ...................................................................9

5 Technical specifications...............................................................................................................10

5.1 Dimensions............................................................................................................................10

5.2 Environmental conditions ...................................................................................................... 10

5.3 Mechanical specifications......................................................................................................10

5.4 Electrical properties...............................................................................................................11

5.5 EMC values ...........................................................................................................................11

5.6 Ports and interfaces ..............................................................................................................12

6 Electrical connection ....................................................................................................................13

6.1 Pin assignment - Power supply/CAN/ignition ........................................................................ 13

7 Programming.................................................................................................................................14

7.1 Device status.........................................................................................................................14

7.2 Setting the node ID................................................................................................................14

7.3 CAN identifier ........................................................................................................................ 14

7.4 CAN communication..............................................................................................................14

7.4.1 NMT commands ........................................................................................................14

7.4.2 Heartbeat...................................................................................................................14

7.4.3 TXPDO1 ....................................................................................................................15

7.4.4 RXPDO1....................................................................................................................15

7.4.5 SDO communication .................................................................................................15

7.5 Encoder configuration ...........................................................................................................16

7.6 System parameters ............................................................................................................... 17

7.7 Troubleshooting.....................................................................................................................17

8 Maintenance and repairs ..............................................................................................................18

Table of contents Jetter AG

iv JXM-HMI User Manual

8.1 Maintenance, repairs and disposal........................................................................................18

8.2 Storage and shipment ........................................................................................................... 18

9 Service ...........................................................................................................................................19

9.1 Customer service ..................................................................................................................19

Jetter AG Introduction | 1

JXM-HMI User Manual 5 / 22

1 Introduction

1.1 Information on this document

This document forms an integral part of the product and must be read and under-

stood prior to using it. It contains important and safety-related information for the

proper use of the product as intended.

Target groups This document is intended for specialists with appropriate qualifications.

Only competent and trained personnel are allowed to commission and operate

this device.

During the whole product life cycle, safe handling and operation of the device

must be ensured. In the case of missing or inadequate technical knowledge or

knowledge of this document any liability is excluded.

Availability of infor-

mation

Make sure this document is kept at the ready in the vicinity of the product

throughout its service life.

For information on new revisions of this document, visit the download area on our

website. This document is not subject to any updating service.

Start | Jetter - We automate your success.

For further information refer to the following information products:

■Version updates

Information about new versions of software products or of the operating sys-

tem of your controller.

■Online help of the JetSym software

Detailed description of software functions with application examples

■Application-oriented manuals

Information on file systems and communication interfaces

1.2 Typographical conventions

This manual uses different typographical effects to support you in finding and

classifying information. Below, there is an example of a step-by-step instruction:

üThis symbol indicates requirements which have to be met before executing

the following action.

►This sign or a numbering at the beginning of a paragraph marks an action in-

struction that must be executed by the user. Execute the instructions one after

the other.

ðThe target after a list of instructions indicates reactions to, or results of these

actions.

More information on this subject is available on our website.

Start | Jetter - We automate your success.

INFO “Info" provides you with useful information and practical tips about the product.

Jetter AG Safety | 2

JXM-HMI User Manual 6 / 22

2 Safety

2.1 General information

At the time of placing on the market, this product corresponds to the current state

of the art and meets the recognized safety rules.

Besides this user manual, laws and regulations in the operator's country are rele-

vant to the operation of the product. The operator is responsible for complying

with the directives mentioned below:

■Applicable legislation, rules, and regulations

■Relevant accident prevention regulations

■Accepted safety rules

■EU directives and other country-specific regulations

RoHS 2 The device conforms to the EU directive 2011/65/EU (RoHS 2).

2.2 Warnings used in this document

DANGER High risk

Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING Medium risk

Indicates a potential hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION Low risk

Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

NOTICE Material damage

Indicates a situation which, if not avoided, could result in malfunctions or material

damage.

2.3 Usage other than intended

This device must not be used in technical systems which to a high degree have

to be fail-safe.

Machinery Directive This device is no safety-related part as per Machinery Directive 2006/42/EC, and

must, therefore, not be used for safety-relevant applications. This device is NOT

intended for the purpose of personal safety, and must, therefore, not be used to

protect persons.

Jetter AG Product description | 3

JXM-HMI User Manual 7 / 22

3 Product description

The JXM-HMI is a universal human-machine interface with three rugged push en-

coders. It is therefore ideally suited for a wide range of dosing and control appli-

cations in self-propelled machines. Thanks to its compact design, the JXM-HMI

can be flexibly mounted individually or in combination with a JetViewMobile 104,

for example, in the driver's cabin. Integrated LEDs ensure that the push encoders

are always perfectly visible.

The CANopen® communication interface lets you connect the module to common

CAN networks of self-propelled machines.

3.1 Features

■1 CAN port with terminating resistor

■Communication via CANopen® protocol

■Adjustable key illumination

■3 push encoders

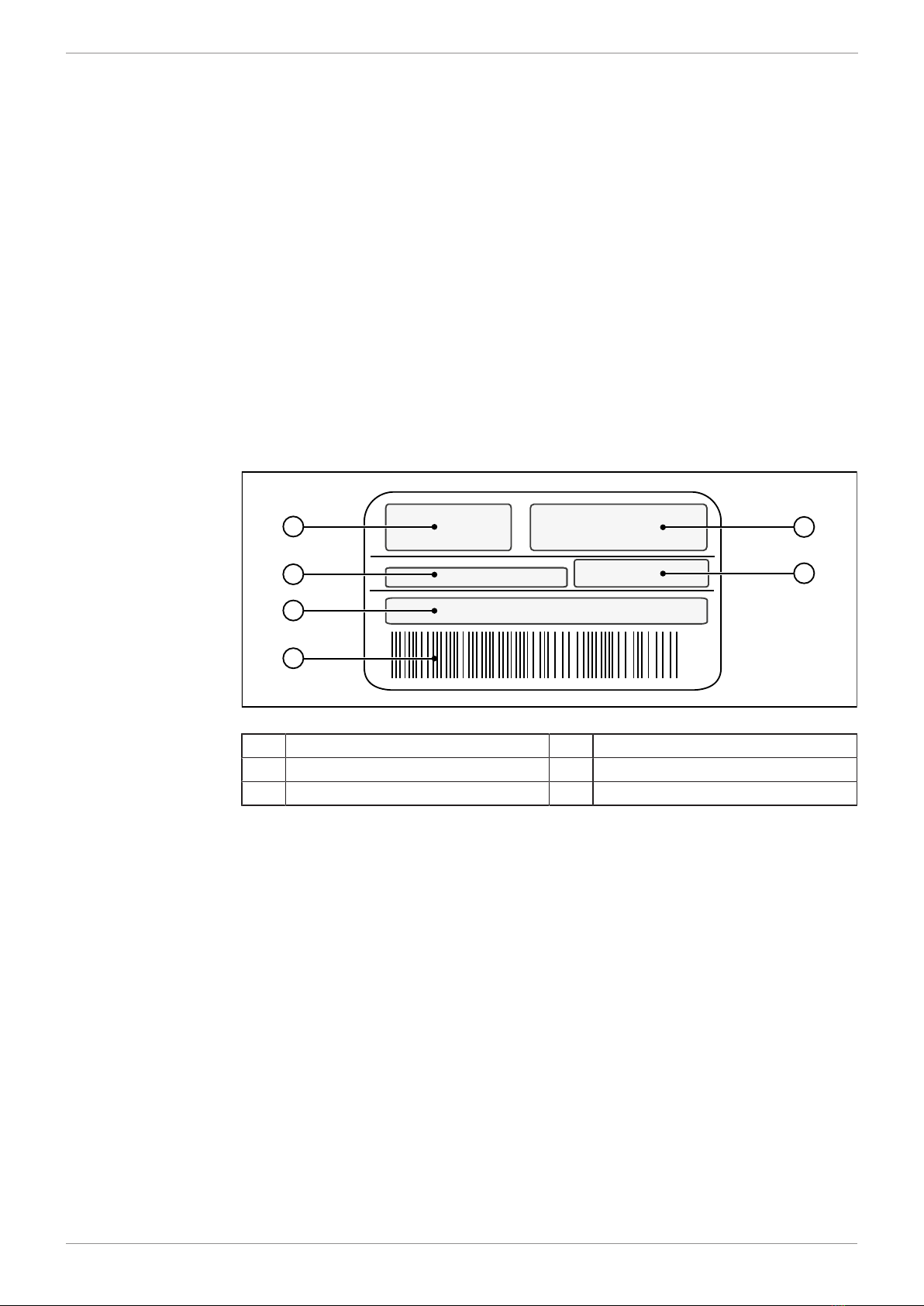

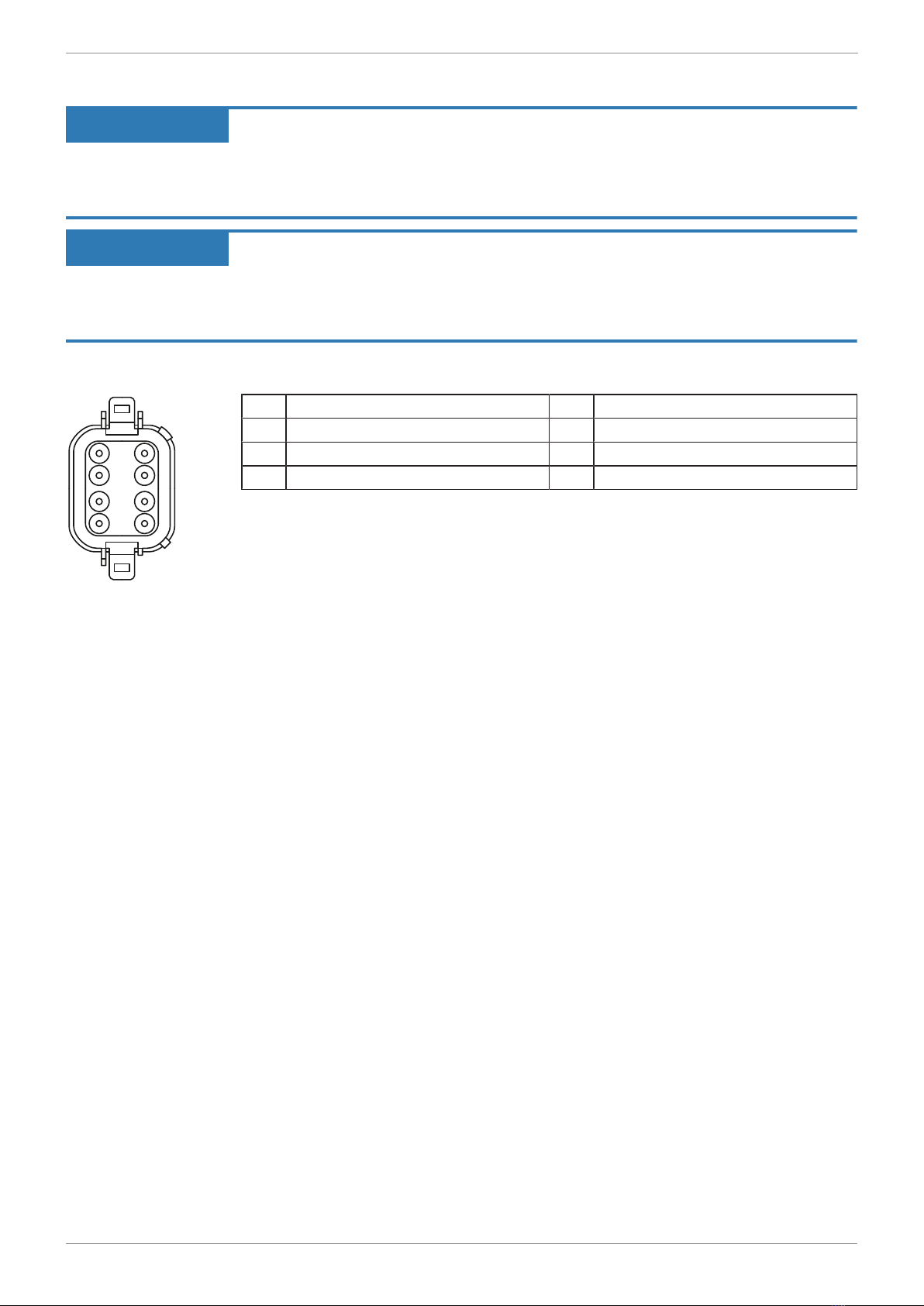

3.2 Nameplate

1

6

5

4

3

2

Fig.1: Sample nameplate

➀Logo ➁Certification mark

➂Item number ➃Barcode

➄Serial number ➅Model code number

Jetter AG Mechanical installation | 4

JXM-HMI User Manual 8 / 22

4 Mechanical installation

Mount the JXM-HMI only in a suitable place in the vehicle interior.

NOTICE Damages to material or functional impairment

Welding on the chassis may cause damages to material of the device, or impair

its functions.

● Before you start welding, disconnect all connections between the device and

the electric system of the vehicle.

● Protect the device from flying sparks and welding beads (splatter).

● Do not touch the device with the welding electrode or earth clamp.

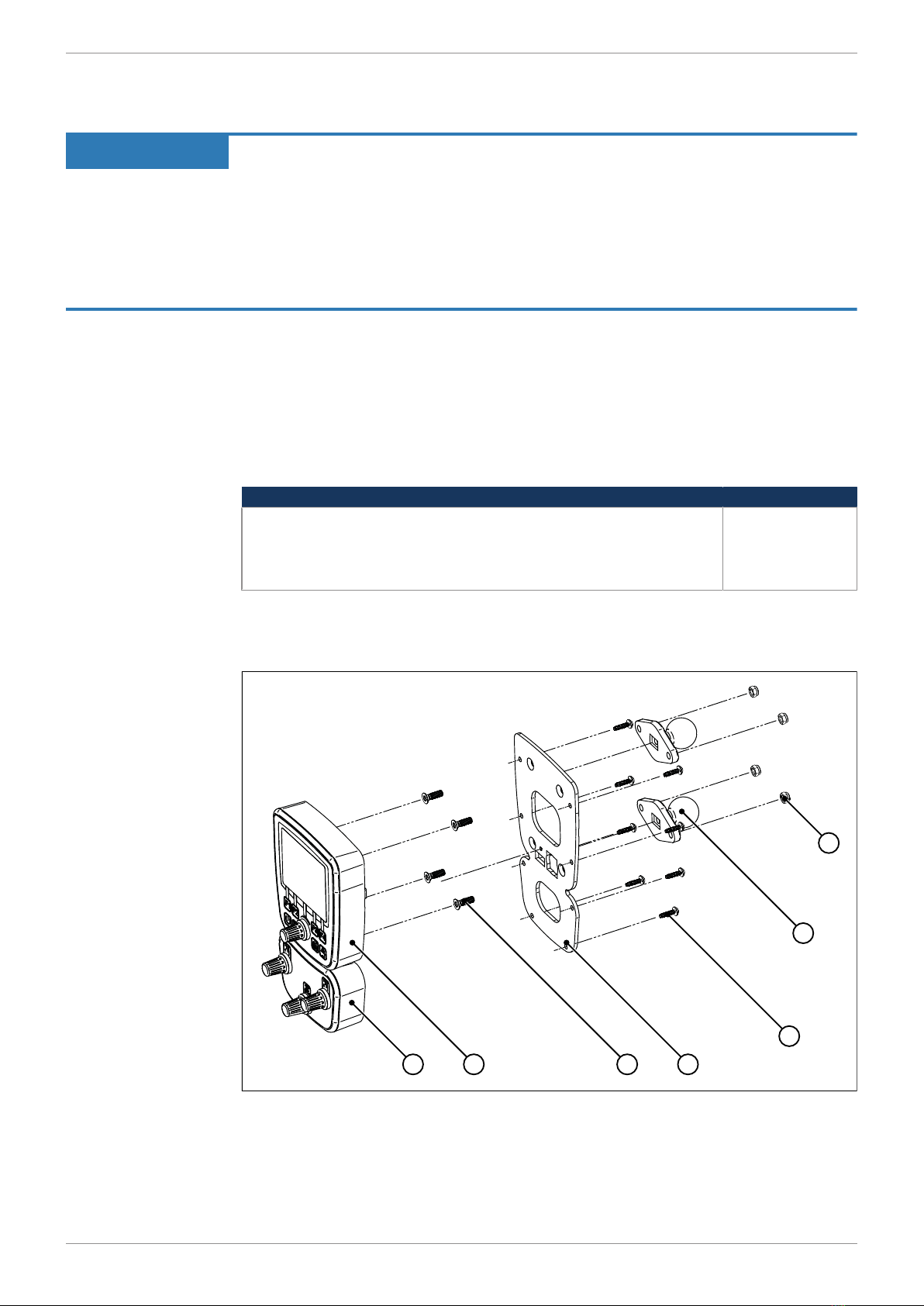

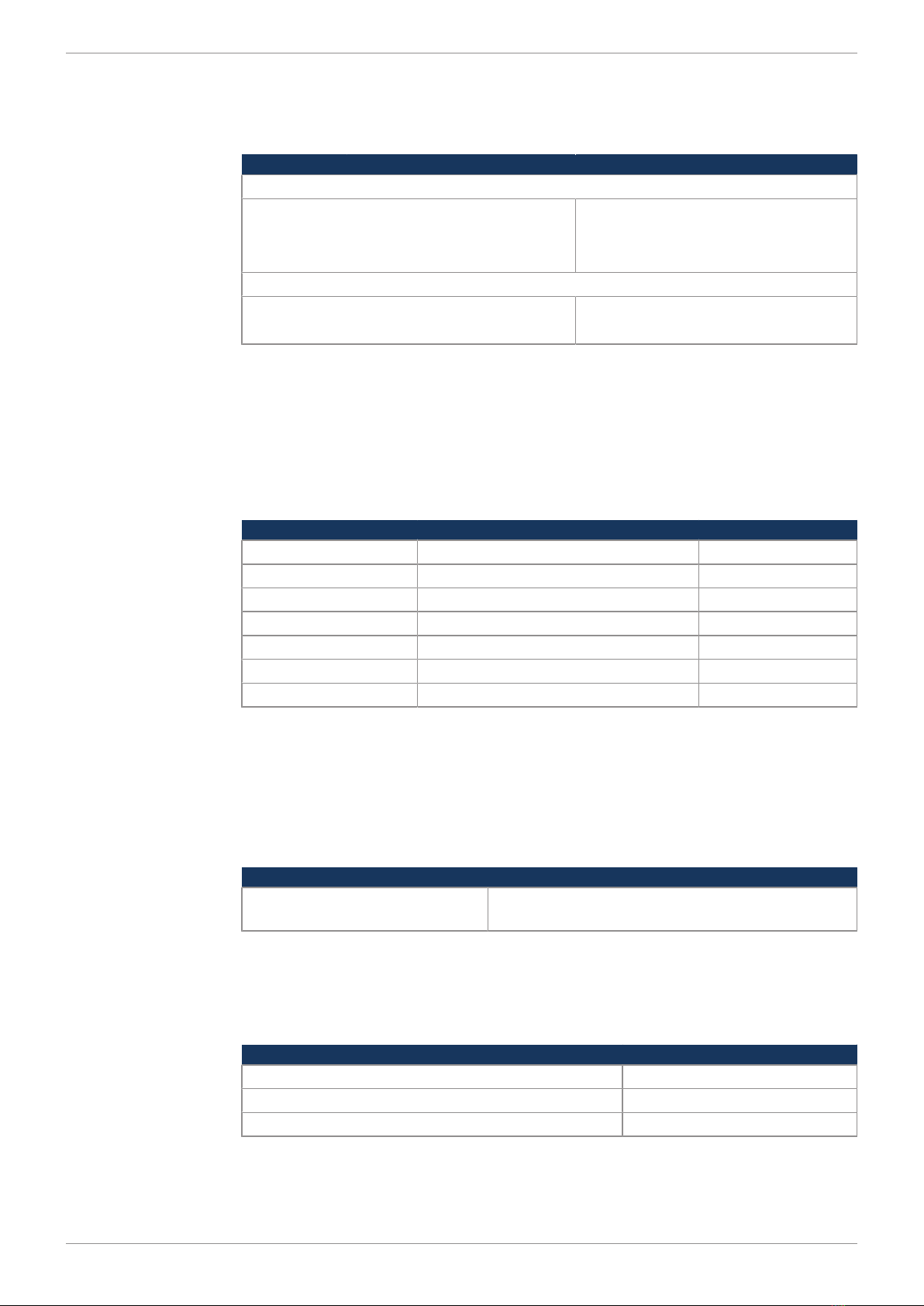

4.1 Mounting in combination with a JVM-104

The JXM-HMI is particularly well suited for use in conjunction with the JVM-104

HMI. A special mounting plate is available for this purpose which enables both

devices to be mounted together.

Mounting Acces-

sories

Use the following accessories for installation:

Accessories Item number

Holding plate for combination of JXM-HMI and JVM-104 for

RAM Mount ball

consisting of mounting plate and screws for housing with

Deutsch or M12 connector, without RAM mount attachments

10001832

Tab.1: Mounting Accessories

The illustration below shows how to install the device:

1 2 43

7

6

5

Fig.2: Installation drawing

Jetter AG Mechanical installation | 4

JXM-HMI User Manual 9 / 22

➀JXM-HMI ➁JVM-104

➂2 x countersunk screws for

mounting a RAM Mount ball ➃Mounting plate with opening for

connector

➄

8 x screws for fixing the mount-

ing plate to the JXM-HMI and

JVM-104

➅RAM Mount ball

➆2 x self-locking nuts

1. Screw the desired RAM Mount attachments onto the mounting plate.

2. Hold the JXM-HMI and the JVM-104 against the mounting plate from behind.

The connectors must be accessible through the openings in the mounting

plate.

3. Screw the mounting plate onto the JVM-104 and the JXM-HMI.

Installing the strain

relief

Install strain reliefs for the connecting cables.

■Ensure that there is sufficient clearance between the strain reliefs and the con-

nectors.

■Connectors must not be obstructed, so that they can be removed in the event

of service.

4.1.1 Requirements for the installation location

■The installation surface must be level.

■The installation surface should be no more than 5 mm thick.

■The installation location must allow air to circulate.

■The installation compartment must allow adequate air circulation.

■The installation location must be of sufficient size.

■The device must be easily accessible to allow for service work.

Space required for

installation and ser-

vice

It must be possible to disconnect the connectors at any time.

Avoiding unsuit-

able installation lo-

cations

The following installation locations are unsuitable for installation:

Unsuitable installation location Reason

Outdoor installation The device must not be exposed to rain

or a jet of water. Do not use a steam jet

or other such devices to clean the de-

vice.

This location is not ventilated. The JVM-104 could overheat as heat

builds up.

Installation location close to heat-sensi-

tive materials

The materials could become warped or

misshapen as a result of heat produced

by the device.

Installation surfaces are uneven. The installation surface could become

misshapen when fitting the device. Fas-

tening is unstable and precarious.

Jetter AG Technical specifications | 5

JXM-HMI User Manual 10 / 22

5 Technical specifications

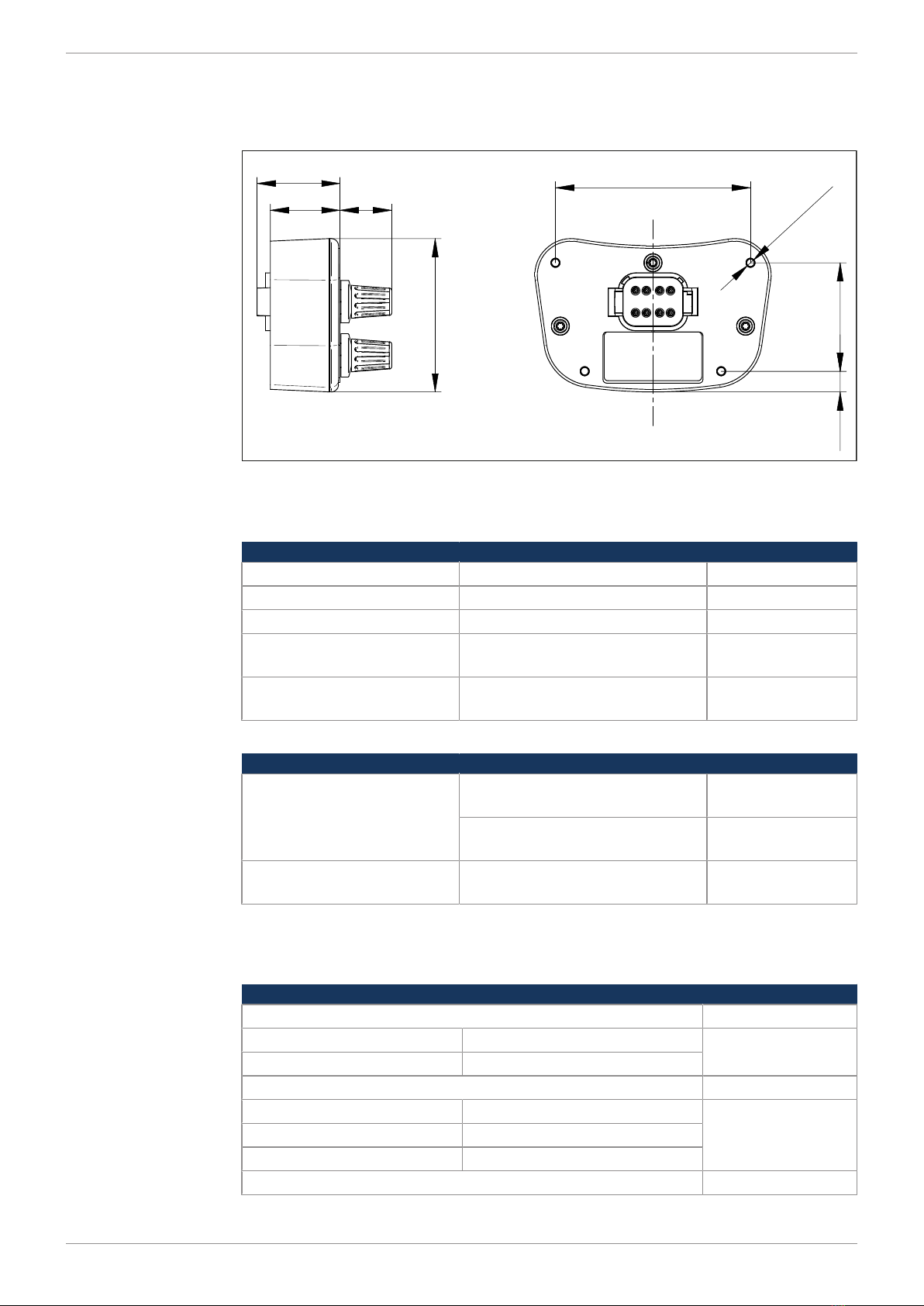

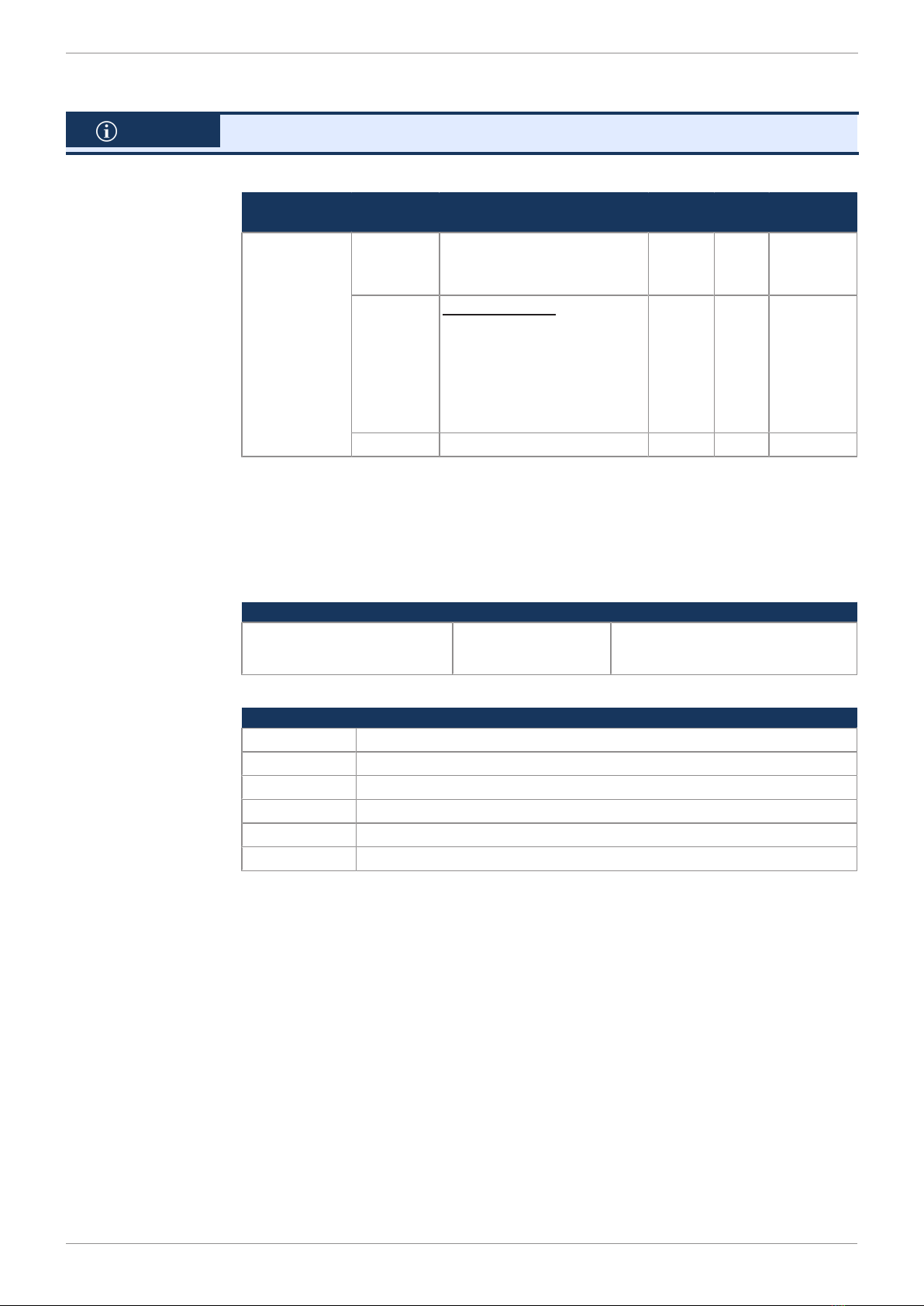

5.1 Dimensions

62.9

28.5

33.9

21.3

80

44.5

8.5

3.2

Ø

Fig.3: Dimensions (in mm)

5.2 Environmental conditions

Category Description Standards

Operating temperature -30 … +85 °C

Storage temperature -30 … +85 °C

Relative humidity 5 ... 95 %

Installation location The device must be installed in

the driver's cab.

Degree of protection IP42 with mating connector

plugged in

ISO 20653:2013

Tab.2: Environmental conditions

Climatic tests Category Standards Functional class

Temperature, cyclically DIN EN 60068-2-14

(2 cycles for function test)

A

DIN EN 60068-2-14

(5 cycles for material test)

C

Humidity/temperature,

cyclically

DIN EN 60068-2-38

(-10 °C ... 55 °C)

A

Tab.3: Climatic tests

5.3 Mechanical specifications

Category Description Standards

Vibration ISO 16750-3

Floating frequency 10 … 150 Hz

Period 6 h

Shock resistance ISO 16750-3

Type of shock Half-sine wave

Intensity and duration 50 g (500 m/s²) for 18 ms

Number and direction 10 shocks in all 6 directions

Height of fall ISO 16750-3

Jetter AG Technical specifications | 5

JXM-HMI User Manual 11 / 22

Category Description Standards

Free fall 1 m onto solid ground or steel

plate

Tab.4: Mechanical specifications

5.4 Electrical properties

Category Description

Abbreviation VBAT_ECU

Operating voltage 8 … 32 V DC

Tab.5: Power Supply

5.5 EMC values

The JXM-HMI has E1 approval according to ECE R10 Rev. 5 and CE conformity

according to ISO 14982.

Pulses to ISO

7637-2

Test pulse Values Functional class

1 -450V C

2a +37V B

2b +20V C

3a -150V A

3b +150V A

4 (24 V) Ua1: -12 V / 50 ms

Ua2: -5 V / 500 ms

A

4 (12 V) Ua1: -6V / 15 ms

Ua2: -2.5 V / 1000 ms

A

5b Load dump

70V / 2Ω / 350 ms

A (as of HW revision

02.00)

E (up to HW revision

01.00)

Tab.6: Pulses to ISO 7637-2

ESD EN 61000-4-2 Category Values Functional class

Contact discharge ±4 kV (to conductive sur-

faces)

A

Discharge through air ±8 kV (to insulating sur-

faces)

A

Tab.7: ESD EN 61000-4-2

Radiated electro-

magnetic energy

ISO 11452-2 2004

and ISO 11452-4

2004

Category Values Functional class

Protection against RF

noise

20 MHz ... 2 GHz 30 V/m A

Tab.8: Irradiation to ISO 11452

Jetter AG Technical specifications | 5

JXM-HMI User Manual 12 / 22

5.6 Ports and interfaces

CAN port Category Description

Baud rate 125 kBaud ... 1 MBaud

Protocol CANopen®

Default node ID on the CANopen®

bus

0x11

Terminating resistor Integrated

Connector specifications Twisted pair conductors, unshielded

CANopen® ports 1

Protection ■Short circuit

■Overvoltage protection (32 V max.)

Tab.9: CAN port

Jetter AG Electrical connection | 6

JXM-HMI User Manual 13 / 22

6 Electrical connection

NOTICE Damages to material or functional impairment

Improper implementation of the wiring harness may cause mechanical stress.

● Protect the cables from bending, twisting or chafing.

● Install strain reliefs for the connecting cables.

NOTICE Overvoltage due to missing external fuses

High voltages can impair the functions of the device or damage the device.

● Make sure that the voltage inputs are fused according to the requirements.

● Observe the ESD principles when handling the device.

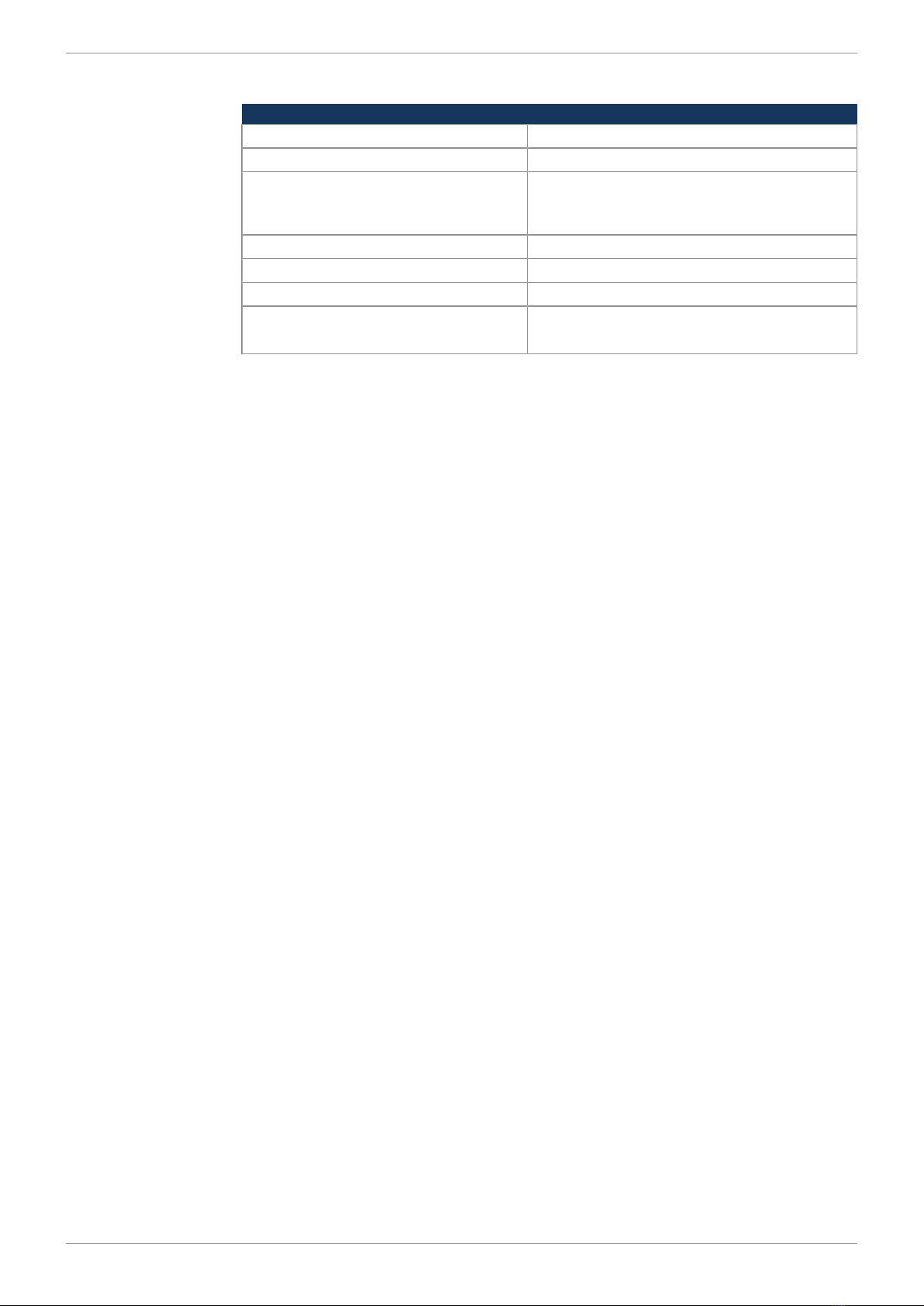

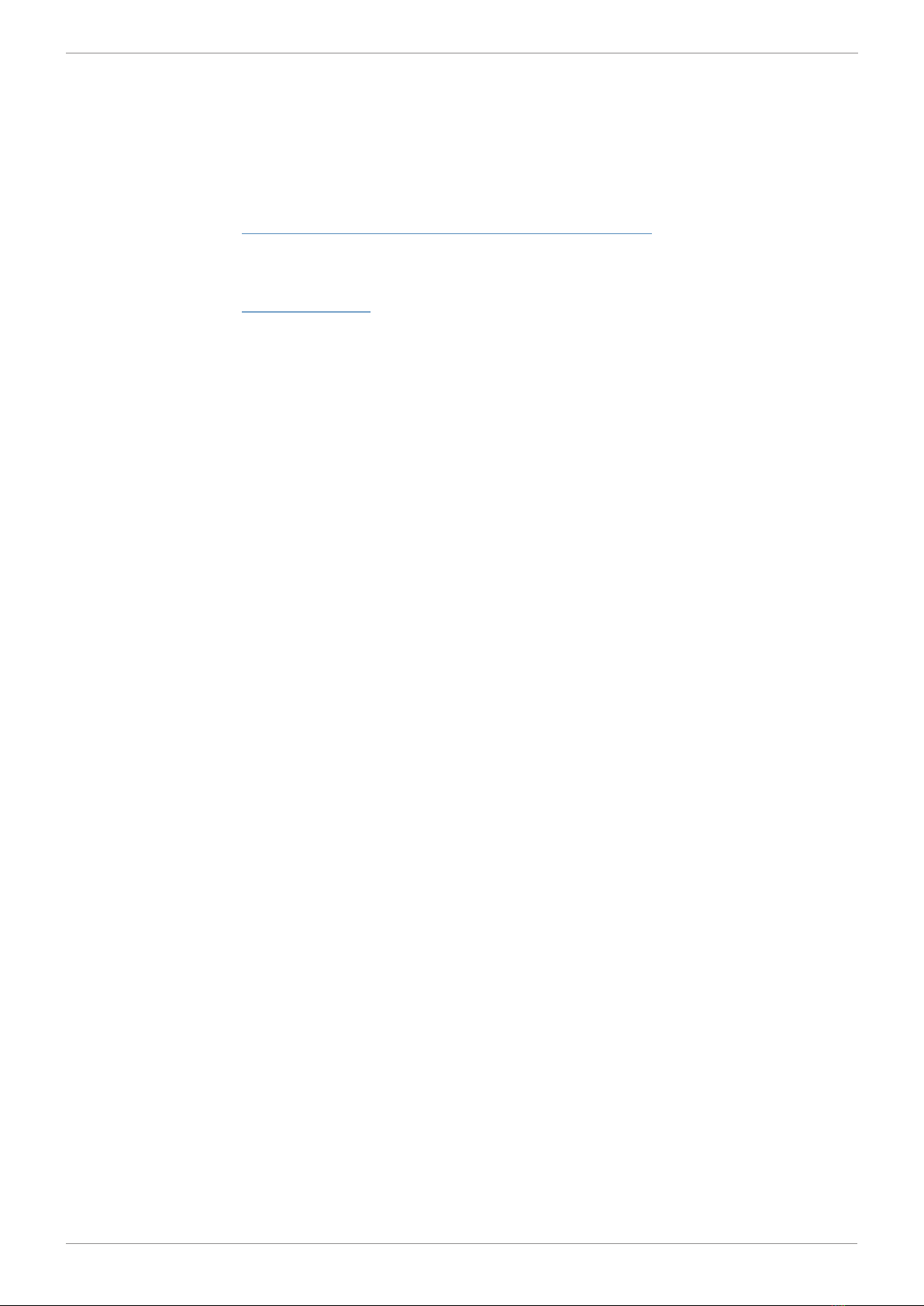

6.1 Pin assignment - Power supply/CAN/ignition

4

3

2

1

5

6

7

8

Fig.4: Deutsch connec-

tor, 8 pins

4 VBAT_ECU 5 VBAT_ECU

3 GND_IN 6 GND_OUT

2 CAN_H_IN 7 CAN_H_OUT

1 CAN_L_IN 8 CAN_L_OUT

Jetter AG Programming | 7

JXM-HMI User Manual 14 / 22

7 Programming

7.1 Device status

Status Condition Features

Bootloader PRE-OPERATIONAL

No firmware present ■Information SDOs are accessible

■Firmware update possible

■Heartbeat

OPERATIONAL

Firmware successfully started ■All SDOs are accessible

■Heartbeat

Tab.10: Device status

7.2 Setting the node ID

The default node ID of the JXM-HMI is 0x11 hexadecimal. The node ID can be

changed by SDO via the System parameters [}17].

7.3 CAN identifier

Message type Description CAN identifiers

NMT Network Management Telegram 0x000

SDO TX Service Data Object receive 0x580 + node ID

SDO RX Service Data Object send 0x600 + node ID

TXPDO1 Process Data Object send 0x180 + node ID

RXPDO1 Process Data Object receive 0x200 + node ID

EMCY Emergency message 0x80 + node ID

Error control Error Control Protocol (Heartbeat) 0x700 + node ID

Tab.11: CAN identifiers

7.4 CAN communication

7.4.1 NMT commands

The JXM-HMI changes into OPERATIONAL mode immediately after switching

on. The following NMT commands are supported:

NMT commands Description

Reset Node The node is reloaded and all settings are set to

their default values.

Tab.12: NMT commands

7.4.2 Heartbeat

The device sends a heartbeat message in a 1 s cycle. If the heartbeat is not

transmitted within 3 s, the HMI is not active.

Description Byte 0

BOOTUP CMD 0

OPERATIONAL CMD 5

PRE-OPERATIONAL CMD 127

Tab.13: Index of the heartbeat message

Jetter AG Programming | 7

JXM-HMI User Manual 15 / 22

7.4.3 TXPDO1

TXPDO1 is sent each time the encoder values change, but not more than once

per 100 ms. Encoder values are values of a free-running counter. With a positive

overflow the value changes to 0x0, with a negative overflow to 0xffff. Dynamiza-

tion can take place in the controller.

Byte 0/1 Byte 2/3 Byte 4/5 Byte 6

Uint16_t

Encoder 1 value

Uint16_t

Encoder 2 value

Uint16_t

Encoder 3 value

Encoder return:

Bit 0 = Encoder 1

Bit 1 = Encoder 2

Bit 2 = Encoder 3

Tab.14: TXPDO1

7.4.4 RXPDO1

Telegrams sent to the JXM-HMI in OPERATIONAL mode:

Description Byte 0 Byte 1 Byte 2 Byte 3/4 Byte 5 Byte 6/7

Key illumination/

LED control

(cyclic transmis-

sion)

1 Key illumi-

nation

0 … 100

%

Tab.15: RXPDO1

7.4.5 SDO communication

According to CANopen® the following indices can be queried:

Index Subindex Description Typ

eDir Default value

0x1000 0 Device type U32 R

0x1001 0 Error register:

Bit 0: Generic error

Bit 3: Temperature

Bit 4: Communication error

U32 R

0x1008 0 Device Name STR R

0x1009 0 Hardware revision of device STR R

0x100A 0 Software version of device STR R

0x1018 0 Number of supported en-

tries

U8 R

1 Distributor ID U32 R 0x000000B3

(Jetter's distributor

ID)

2 Product code U32 R

3 Revision number U32 R

4 Serial number U32 R

Tab.16: SDO communication

Jetter AG Programming | 7

JXM-HMI User Manual 16 / 22

7.5 Encoder configuration

Index Subindex Description Type Dir Default

value

0x2002…

0x2004

Encoder 1 ...

encoder 3

0 Number of supported en-

tries

U8 R 7

1 Bit 0 = 0

Increment direction right

Bit 0 = 1

Increment direction left

U8 R/W 0

Bit 1 = 0

Dynamization OFF

Bit 1 = 1

Dynamization ON

U8 R/W 0

Bit 2 = 0

Limit values OFF

Bit 2 = 1

Limit values ON

U8 R/W 0

2 Rotary pulse/second up to

level 1

U16 R/W 4

3 Level 1 step size U16 R/W 10

4 Rotary pulse/second up to

level 2

U16 R/W 7

5 Level 2 step size U16 R/W 100

6 Rotary pulse/second up to

level 3

U16 R/W 10

7 Level 3 step size U16 R/W 1000

8 Minimum value U16 R/W 0

9 Max. value U16 R/W 0

10 Value/encoder output

(analog to TXPDO1 [}15])

U16 R/W 0

Tab.17: Encoder configuration

Jetter AG Programming | 7

JXM-HMI User Manual 17 / 22

7.6 System parameters

INFO You can only use the set system parameters after restarting the system.

Index Subindex Description Type Dir Default

value

0x4556 0 Number of supported en-

tries

U8 R 4

3 CAN baud rate:

3 = 1 MBaud

2 = 500 kBaud

1 = 250 kBaud

0 = 125 kBaud

U8 R/W 1

4 CANopen® node ID U8 R/W 0x11

Tab.18: System parameters

7.7 Troubleshooting

EMCY telegrams are sent at startup or after any changes at an inhibit time of 50

ms (minimum pause between 2 telegrams). An EMCY telegram is sent when an

event is started or changed.

Emergency object

telegrams (EMCY

telegrams)

Byte 0/1 Byte 2 Byte 3-7

Emergency Error Code Error register

Object 0x1001

Manufacturer specific error field

Always 0 is sent.

Tab.19: Bit values of emergency objects

Error memory (er-

ror history)

Code Description

0x0000 No error or error reset

0x1000 Generic error

0x3100 Voltage VBAT_ECU exceeds the permitted limits

0x4200 Device temperature is too high

0x8110 CAN data overrun (lost objects)

0x8140 Recovered from bus-off

Tab.20: Emergency Error Codes

Jetter AG Maintenance and repairs | 8

JXM-HMI User Manual 18 / 22

8 Maintenance and repairs

8.1 Maintenance, repairs and disposal

Maintenance This device is maintenance-free.

Therefore, for the operation of the device no inspection or maintenance are re-

quired.

Repairs Defective components could cause dangerous malfunctions and could compro-

mise safety.

Only the manufacturer is allowed to repair the device.

Do not open the device!

Disposal of obso-

lete equipment

The device must be disposed of in accordance with the Environmental Product

Declaration EPD. Applicable local environmental directives and regulations must

be complied with. This product must be disposed of as waste electronic equip-

ment. Waste packaging material must be recycled or reused.

Modifications and

alterations to the

device

Modifications and alterations to the device and its functions are not allowed. In

the case of modifications to the device, any liability is excluded.

The original parts are specifically designed for the device. Parts and equipment

from other manufacturers must, therefore, not be used.

Any liability for any damages resulting from the use of non-original parts and

equipment is excluded.

8.2 Storage and shipment

Storage When storing the device observe the environmental conditions given in chapter

“Technical specifications”.

Shipment and pack-

aging

The device contains electrostatically sensitive components which can be dam-

aged if not handled properly. Damages to the device may impair its reliability.

To protect the device from impact or shock, it must be shipped in its original

packaging, or in an appropriate protective ESD packaging.

In case of damaged packaging inspect the device for any visible damage, and in-

form your freight forwarder and the Jetter AG of the damage caused during ship-

ment. If the device is damaged or has been dropped, it is strictly forbidden to use

it.

Jetter AG Service | 9

JXM-HMI User Manual 19 / 22

9 Service

9.1 Customer service

Should you have any questions, suggestions, or problems, please don’t hesitate

to contact our service representatives. To contact them, please call our technical

hotline or use the contact form on our homepage:

Technical hotline | Jetter - We automate your success.

You are also welcome to send an e-mail to our technical hotline:

Please supply the following information when contacting our technical hotline:

■Hardware revision and serial number

For the hardware revision number, please refer to the nameplate.

Jetter AG List of figures

JXM-HMI User Manual 20 / 22

List of figures

Fig. 1 Sample nameplate .................................................................................................................. 7

Fig. 2 Installation drawing.................................................................................................................. 8

Fig. 3 Dimensions (in mm) ................................................................................................................ 10

Fig. 4 Deutsch connector, 8 pins....................................................................................................... 13

This manual suits for next models

1

Table of contents

Other Jetter Recording Equipment manuals