6 JLA Limited 113372-16

MAXIMUM CAPACITY(DRYWEIGHT) 75 lb 34.0 kg

TUMBLER DIAMETER 37” 94 cm

TUMBLER DEPTH 36” 91.5 cm

TUMBLER VOLUME 22.4 cu ft 634.30 L

TUMBLER / DRIVE MOTOR 1 hp*0.75 kW

BLOWER / FAN MOTOR N / A

DOOR OPENING (DIAMETER) 31-3/8” 79.69 cm

DOOR SILL HEIGHT N / A

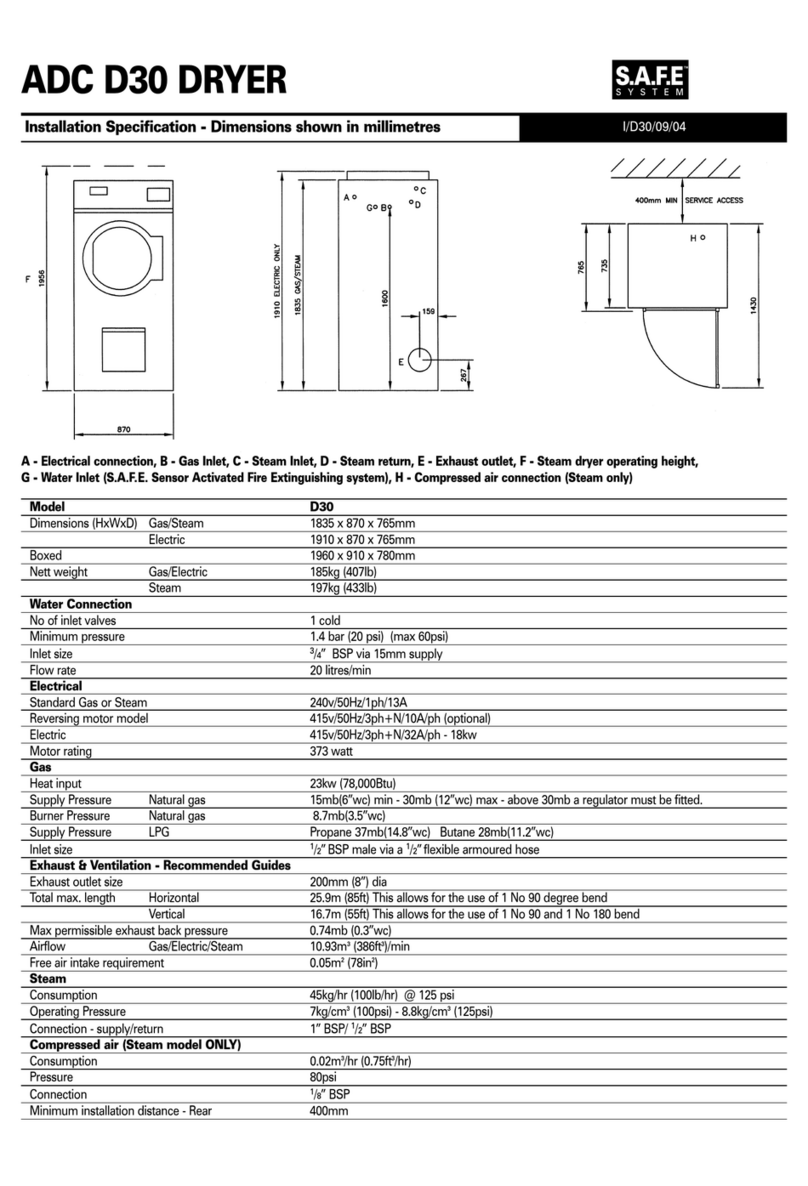

WATER CONNECTION 3/4” B.S.P.T.

DRYERS PER 20’/40’ CONTAINER 9 / 20

DRYERS PER 48’/53’ TRUCK 24 / 26

VOLTAGE AVAILABLE 120-480V 1,3ø 2,3,4w 50/60 Hz

APPROXIMATE NET WEIGHT 741 lb 336.1 kg

APPROXIMATE SHIPPING WEIGHT 793 lb 359.7 kg

AIRFLOW 60 Hz 1,000 cfm 28.32 cmm

50 Hz 840 cfm 23.78 cmm

HEATINPUT 175,000 Btu/hr 44,100 kcal/hr

EXHAUST CONNECTION (DIAMETER) 8” 20.32 cm

COMPRESSED AIR CONNECTION N / A

COMPRESSED AIR VOLUME N / A

INLET PIPE CONNECTION 3/4” B.S.P.T.

VOLTAGE AVAILABLE

N / A

APPROXIMATE NET WEIGHT

APPROXIMATE SHIPPING WEIGHT

AIRFLOW 60 Hz

50 Hz

EXHAUST CONNECTION (DIAMETER)

COMPRESSED AIR CONNECTION

COMPRESSED AIR VOLUME

OVEN SIZE

kW Btu/hr kcal/hr

30 102,387 25,802

VOLTAGE AVAILABLE 120-575V 1,3ø 2,3,4w 50/60 Hz

APPROXIMATE NET WEIGHT 816 lb 370.13 kg

APPROXIMATE SHIPPING WEIGHT 868 lb 393.72 kg

AIRFLOW 60 Hz 1,200 cfm 33.98 cmm

50 Hz 1,000 cfm 28.32 cmm

STEAM CONSUMPTION 275 lb/hr 124.7 kg/hr

OPERATING STEAM PRESSURE 125 psi max 8.62 bar

EXHAUST CONNECTION (DIAMETER) 8” 20.32 cm

COMPRESSED AIR CONNECTION 1/8” F.N.P.T.

COMPRESSED AIR VOLUME 0.75 cfh 0.02 cmh

BOILER HORSEPOWER (NORMAL LOAD) 7.2 Bhp

SUPPLYCONNECTION (1) 1” N.P.T.

(Female)

RETURN CONNECTION (1) 1” N.P.T.

(Female)

SECTIONII

SPECIFICATIONS/COMPONENTIDENTIFICATION

A. SPECIFICATIONS

NOTE: Themanufacturerreservestherighttomakechangesin specifications atanytimewithout

noticeor obligation.

Shaded areas are stated in metric equivalents 11/12/15

* All reversing dryers are supplied with two (2) 3-phase (3ø) motors standard: a 1 hp (0.75 kW) blower

motor and a 1/2 hp (0.37 kW) drive motor.

** Air-operated steam damper system requires a clean, dry, and regulated 80 psi +/- 10 psi (5.51 bar

+/- 0.69 bar) air supply.

GAS

ELECTRICSTEAM**