SECTION I

SAFETY PRECAUTIONS ..............................................................................................................................2

SECTION II

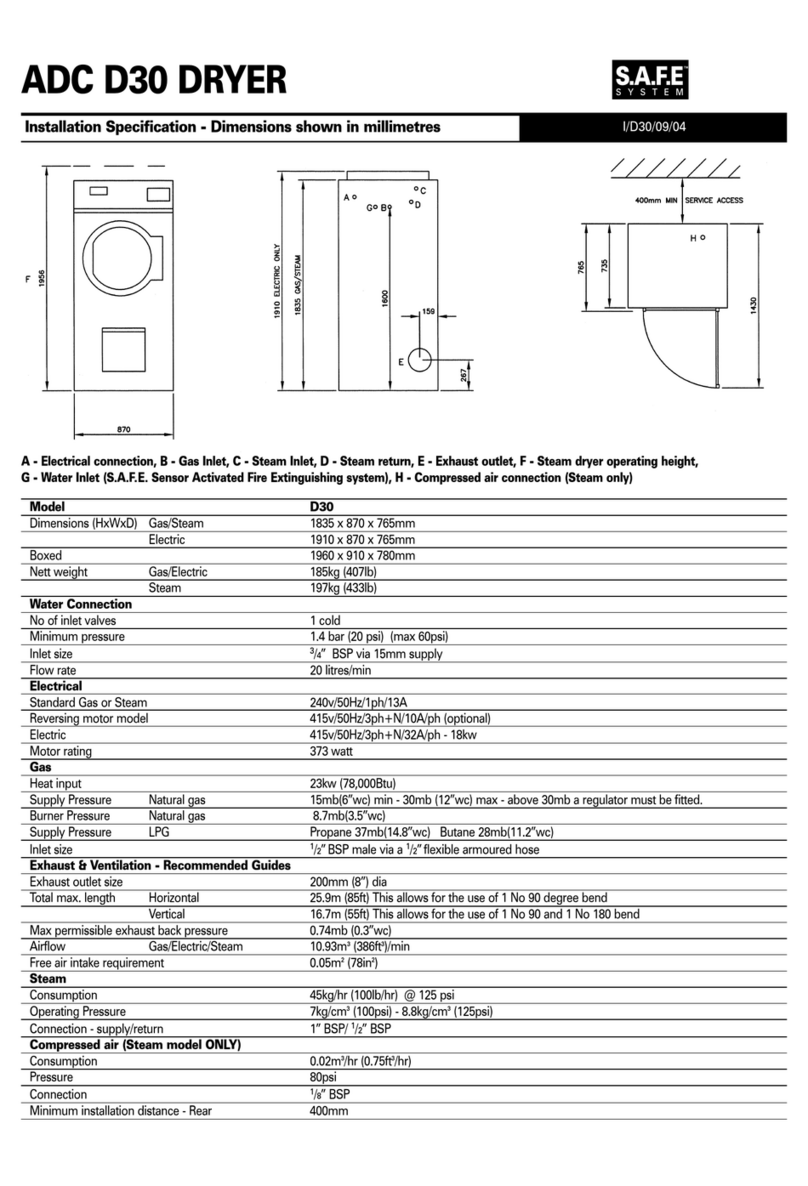

SPECIFICATIONS/COMPONENT IDENTIFICATION .........................................................................4

A. Specifications.......................................................................................................................................... 4

B. ComponentIdentification........................................................................................................................ 6

SECTION III

INSTALLATION PROCEDURES ................................................................................................................8

A. Location Requirements........................................................................................................................... 8

B. Unpacking/Setting Up............................................................................................................................. 9

C. Dryer Enclosure Requirements ............................................................................................................ 10

D. FreshAir Supply Requirements ............................................................................................................ 10

E. Exhaust Requirements.......................................................................................................................... 11

F. Electrical Information ........................................................................................................................... 15

G. Gas Information .................................................................................................................................... 17

H. Water Information ................................................................................................................................ 20

I. Preparation for Operation/Start-Up...................................................................................................... 23

J. Preoperational Tests ............................................................................................................................. 23

K. Compressed Air Requirements............................................................................................................. 25

L. Shutdown Instructions .......................................................................................................................... 26

SECTION IV

SERVICE/PARTS INFORMATION ...........................................................................................................27

A. Service .................................................................................................................................................. 27

B. Parts...................................................................................................................................................... 27

SECTION V

WARRANTY INFORMATION ...................................................................................................................28

A. Returning Warranty Cards ................................................................................................................... 28

B. Warranty ............................................................................................................................................... 28

SECTION VI

ROUTINE MAINTENANCE ......................................................................................................................29

A. Cleaning ................................................................................................................................................ 29

B. Adjustments .......................................................................................................................................... 30

C. Lubrication ............................................................................................................................................ 30

SECTION VII

DATA LABEL INFORMATION .................................................................................................................31

SECTION VIII

PROCEDURE FOR FUNCTIONAL CHECK OF REPLACEMENT COMPONENTS ...................32

SECTION IX

PHASE 7 NON-COIN SYSTEM DIAGNOSTICS....................................................................................33

A. Diagnostic (L.E.D. Display) Fault Messages ...................................................................................... 33

Table of Contents