2 JLA Limited 114134 - 2

Safety Precautions ______________

Only qualified personnel should install, service,

or adjust this equipment.

The information in this manual must be followed to minimize

the risk of fire or explosion and to prevent property damage,

personal injury, or loss of life.

Do not allow children to play on or in the dryer.

Children must be supervised when near an operating dryer.

The appliance can be used by children aged

from 8 years and above and persons with

reduced physical, sensory and mental

capabilities or lack of experience and

knowledge if they have been given supervision

or instruction concerning use of appliance in a

safe way and understand the hazards involved.

Do not modify this appliance.

Do not bypass or disable any door or drawer switch.

Do not bypass or disable any heat safety circuit.

Do not operate with any guards or service panels removed.

Do not operate if the lint filter is not in place.

Do not use dryer in the presence of dry cleaning fumes.

Do not spray aerosols near the dryer while it is operating.

Dry only water washed fabrics. Do not dry articles spotted or

washed in dry cleaning solvents, combustible detergents,

industrial chemicals, or “all-purpose” cleaner.

Do not dry rags or articles coated or contaminated with gasoline,

kerosene, oil, paint, or wax.

Items that have been spotted or soaked with vegetable or

cooking oil constitute a fire hazard and should not be dried.

The presence of residual quantities of aggressive or

decomposed chemicals in the load may damage the machine

or produce harmful fumes.

Do not dry mop heads. Contamination from wax or flammable

solvents are a fire hazard.

Do not store or use gasoline or other flammable liquids or vapors

in the vicinity of this appliance.

A qualified technician must be called if any high-limit thermostat

trips to investigate, and resolve, the issue.

Disconnect power before resetting any safety device.

Do not use heat for drying articles that contain plastic, foam,

sponge rubber, or similarly textured rubber materials.

Lint buildup in the burner area, exhaust duct, and around the

machine is a fire hazard and must be cleaned frequently.

You must disconnect and lockout the electric supply and the

gas supply, before removing any guards.

Label all wires prior to disconnection when servicing the dryer.

Every drying cycle finishes with a cool-down period to remove

heat from the dry load. Never stop the dryer before the end of

the drying cycle unless the load is quickly removed and spread

out to allow the heat to dissipate quickly.

Fabric softeners or similar products should only be used as

recommended by the fabric softener manufacturer.

Exhaust duct outlet should be checked periodically for

blockages, and if any found, removed.

Use this dryer only for its intended purpose, drying fabrics.

Purchaser and user should consult the local gas supplier for

proper instructions to be followed in the event the user smells

gas. The instructions should be posted in a prominent location.

What To Do If You Smell Gas:

• Do not try to operate any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Clear the room, building, and area of all occupants.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

Table of Contents ________________________________________________________________________

SAFETY PRECAUTIONS ...................................................................................................... 2

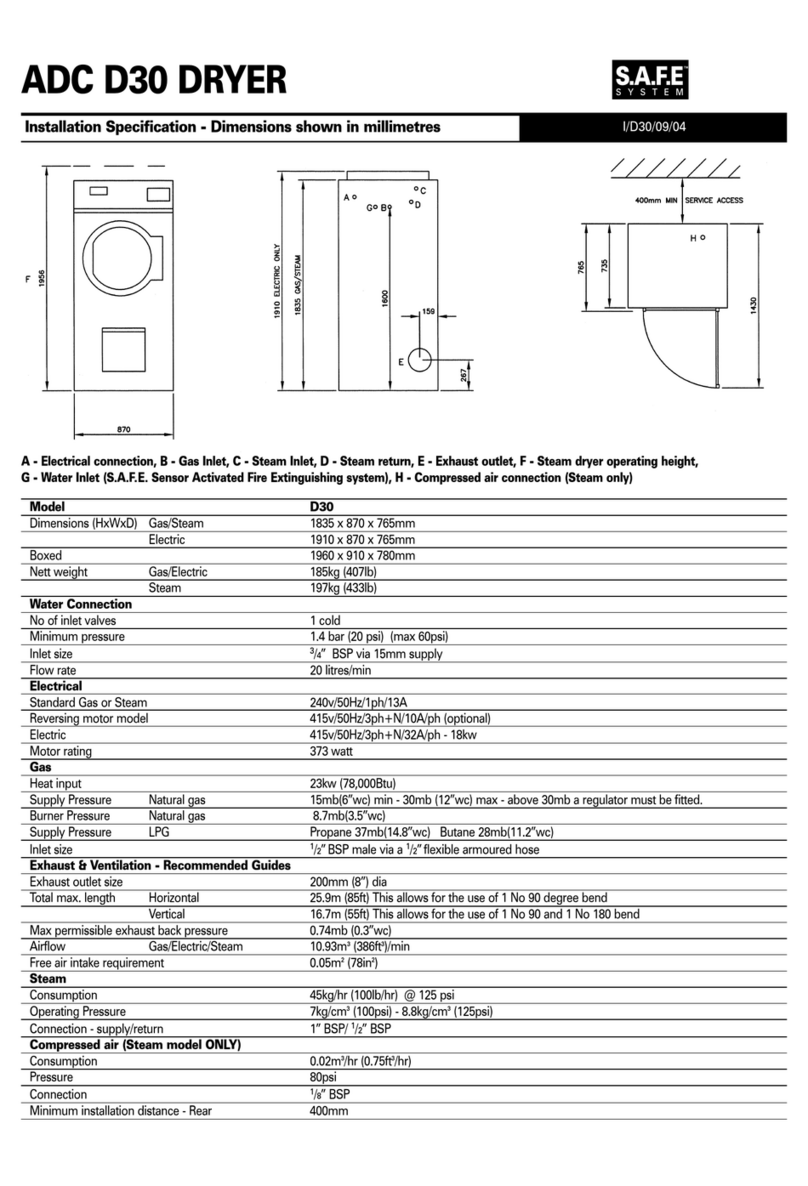

TECHNICAL SPECIFICATIONS ............................................................................................ 3

INSTALLATION PROCEDURES ........................................................................................... 4

LOCATION REQUIREMENTS ............................................................................................... 4

UNPACKING / SETTING UP ................................................................................................. 4

DRYER ENCLOSURE REQUIREMENTS ............................................................................. 4

FRESH (MAKE-UP) AIR SUPPLY REQUIREMENTS ........................................................... 4

EXHAUST REQUIREMENTS ................................................................................................ 4

ELECTRICAL INFORMATION (50HZ) .................................................................................. 6

GAS INFORMATION ............................................................................................................. 8

GAS TYPE CONVERSION .................................................................................................... 9

BURNER PRESSURE MEASURE AND ADJUST ................................................................ 9

WATER INFORMATION ......................................................................................................10

START-UP ............................................................................................................................ 10

PREOPERATIONAL TEST .................................................................................................. 10

OPERATING INSTRUCTIONS ............................................................................................ 10

ROUTINE MAINTENANCE..................................................................................................10

SERVICE / PARTS INFORMATION .................................................................................... 11

DATA LABEL INFORMATION .............................................................................................. 11

WARRANTY INFORMATION .............................................................................................. 11