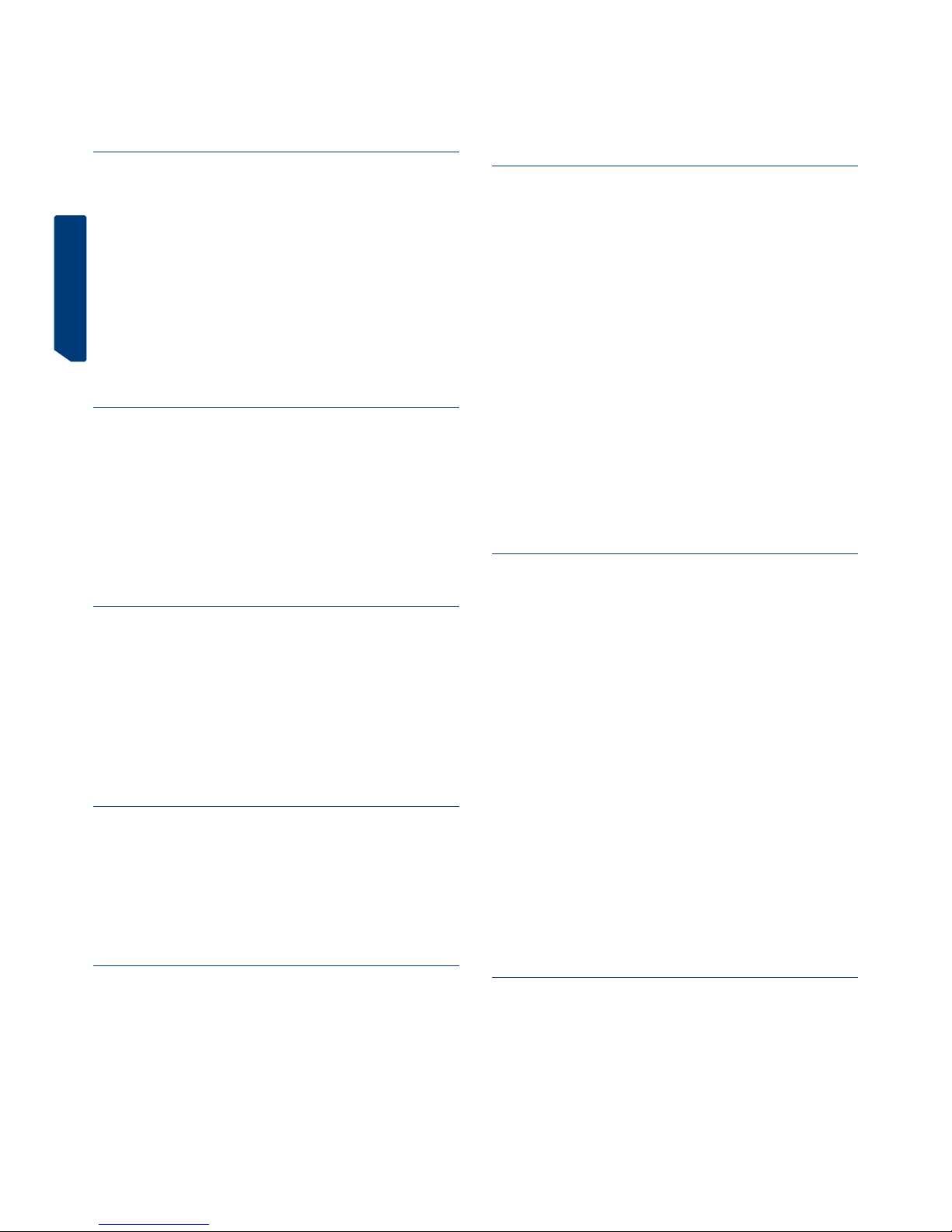

4.3 REPLACING THE TRACER

See figure 16

The procedure for replacing the tracer is as follows:

1) Switch off the machine and unplug the power cable.

2) Fully undo the screw (1) with the help of a 2.5 mm allen key, and remove the tracer

(P).

3) Fit and secure the new tracer, making sure that it rests properly on its rear support

face.

4) It is a good idea to readjust the machine (depth adjustment and side adjustment).

Chapters 3.3 and 3.4 of this manual explain how to carry out these adjustments.

4.4 ADJUSTING THE MAXIMUM DEPTH OF THE SLIDE

See figure 17

In order not to damage the clamps and the cutter, it is necessary to establish a maxi-

mum cutting depth.

The distance between cutter-tracer and clamp has to be 0.1 mm. If this distance is

bigger or smaller, proceed as follows:

1) Switch off the machine and unplug the power cable.

2) Release the slide and move it closer to the cutter-tracer, until it butts up against it.

3) Remove the swarf tray.

4) Loosen the locking nut (2), with a 10 mm spanner.

5) Using a 3 mm allen key, adjust the setscrew (3) until you achieve a separation of

0.1 mm.

6) Tighten up the setscrew (3) with the nut (2), and replace the swarf tray.

4.5 REPLACING THE FUSES

If the machine does not start when you turn on the start switches, you need to check

the state of the fuses.

This operation is done in the following way:

1) Switch off the machine from the master switch and unplug the power cable.

2) Remove the fuse-holder which is to be found next to the master switch.

3) Check (using a tester) if any of the fuses have blown and, if necessary, replace the

blown fuse with one of the same type and value.

4.6 REPLACING THE START SWITCH AND THE BRUSH

BUTTON

See figure 18

This operation is carried out in the following way:

1) Switch off the machine and unplug the power cable.

2) Undo the 6 screws (4) securing the “left side guard”, with the help of a 4 mm allen

key.

3) Carefully turn the “left side guard”, in order to gain access to the switch or button

connectors.

4) Remove the connectors, noting down the position of each of them before hand.

5) Press down on the tabs (5), in order to be able to remove the switch or button.

6) Insert the new switch or button right into its housing.

7) Reconnect each of the connectors in their correct position.

8) Fit the “left side guard” and screw it in place with the 6 screws (4).

4.7 REPLACING AND/OR TIGHTENING THE BELT

See figure 19

To carry out these operations, the sequence is as follows:

1) Switch off the machine and unplug the power cable.

2) Insert the blocking rod into the hole in the cutter shaft.

3) With the help of a 4 mm allen key, undo the screw securing the brush, and remove

the brush.

4) Remove the blocking rod from the cutter shaft.

5) Undo the 6 screws (6) holding the “right side guard” in place, with the help of a 4 mm

allen key, and remove it.

• TIGHTENING:

- Release the tightening screw (7), by loosening the setscrew (8).

- To tighten the belt: Turn the tightening screw (7) clockwise.

- To loosen the belt: Turn the tightening screw (7) anti-clockwise.

- Once you have the tightness required, lock the tightening screw (7) by tightening up

the setscrew (8).

• REPLACEMENT:

- Release the tightening screw (7), by loosening the setscrew (8).

- Loosen the belt, by turning the tightening screw (7) anti-clockwise.

- Remove the old belt. To do this, manually turn the large pulley, and at the same time

apply a little pressure on the side of the belt in the area of the small pulley, until it

comes out of its housing.

- Fit the new belt. To do this, first of all, insert it into the small pulley. Then, to insert it

into the large pulley: manually turn the large pulley whilst applying pressure laterally

on the belt in that area.

- Visually check that the belt has been fitted correctly.

- Tighten the belt, turning the tightening screw (7) clockwise.

- Once you have the tightness required, lock the tightening screw (7) by tightening up

the setscrew (8).

6) Put the “right side guard” into place, and secure it with the 6 screws (6).

7) Insert the blocking rod into the hole in the cutter shaft.

8) Fit the brush, and secure it place with its screw.

9) Remove the blocking rod from the cutter shaft.

4.8 REPLACING THE MOTOR

See figure 20

This operation is carried out as follows:

1) Switch off the machine and unplug the power cable.

2) Remove the swarf tray.

3) Turn the machine, to gain access to the “lower protection plate”.

4) Undo the machine’s 4 feet, and remove them.

5) Unscrew the 5 screws (10) securing the “lower protection plate”, and remove it.

6) Disconnect the motor’s power cable.

7) Screw on the machine’s 4 feet, to be able to support the machine on its feet again.

8) Insert the blocking rod into the hole in the cutter shaft.

9) Undo the screw securing the brush, and remove the brush.

10) Remove the blocking rod from the cutter shaft.

11) Undo the 6 screws (6) securing the “right side guide”, and remove it.

12) Undo the 6 screws (4) securing the “left side guide”, and move it slightly to the left

to gain access to two of the seven screws holding the “motor guard” in place.

13) Undo the 7 screws (9) holding the “motor guard” in place, and remove it.

14) Release the tightening screw (7), by loosening the setscrew (8).

15) Loosen the belt, turning the tightening screw (7) anti-clockwise.

16) Remove the belt. To do this, manually turn the large pulley, and at the same time

exert a little pressure on the side of the belt in the area of the small pulley, until it

comes out of its housing.

17) Undo the 4 screws (11) securing the “motor support”, and remove the motor toge-

ther with the “motor support”.

18) Undo the 4 screws (12) securing the motor to the “motor support”, and remove the

old motor.

19) Undo the setscrew (13) securing the small pulley to the motor, and remove the

small pulley.

20) Insert the small pulley into the new motor, as far as it will go. In this position, screw

in the small pulley with the setscrew (13), making sure that the setscrew is inserted into

the groove in the motor shaft.

21) Fit the new motor onto the “motor support”, so that the sides of the base of the

motor butt up against the heads of the screws sticking out of the “motor support”. In

this position, secure the motor with the 4 screws (12).

22) Secure the “motor support” to the bed, with the 4 screws (11).

23) Fit the belt. To do this, first of all, insert it into the small pulley. Then, to insert it

into the large pulley: manually turn the large pulley whilst applying pressure laterally

on the belt in that area.

24) Visually check that the belt has been correctly fitted.

25) Tighten the belt by turning the tightening screw (7) clockwise.

26) Once the belt is as tight as required, lock the tightening screw (7) by tightening the

setscrew (8).

27) Fit the “motor guard”, securing it in place with the 7 screws (9).

28) Fit the “left side guard”, fixing it in place with the 6 screws (4).

29) Fit the “right side guard”, securing it in place with the 6 screws (6).

30) Insert the blocking rod in the hole in the cutter shaft.

31) Fit the brush, and secure it in place with its screw.

32) Remove the blocking rod from the cutter shaft.

33) Turn the machine to gain access to the bottom area.

34) Connect the motor’s power cable.

35) Undo the machine’s 4 feet and remove them.

36) Fit the “lower protection plate”, securing it in place with the 5 screws (10).

37) Screw on the machine’s 4 feet.

38) Turn the machine so that it is in position ready for use.

39) Fit the swarf tray into the machine.

4.9 REPLACING THE MOTOR CAPACITOR

See figure 21

This operation is carried out in the following way:

1) Switch off the machine and unplug the power cable.

2) Insert the blocking rod into the hole in the cutter shaft.

3) Undo the screw securing the brush, and remove the brush.

4) Undo the 6 screws (6) securing the “right side guard” in place, and remove the

guard.

5) Undo the 6 screws (4) securing the “left side guard” in place, and move it slightly to

the left to gain access to two of the seven screws holding the “motor guard” in place.

6) Undo the 7 screws (9) holding the “motor guard” in place, and remove the guard.

7) Undo the 4 screws (14) holding the “terminal box” cover in place, and remove the

lid.

8) Disconnect the two cables on the old capacitor ( C ) and remove it.