Before using equipment:

1. Only Huck Installation Equipment

should be used to install Huck fasteners.

2. Only persons that have received

training approved by Huck International

Ltd should use Huck Installation

Equipment.

3. The Manuals and/or Data sheets and

warning stickers/labels supplied with the

Installation equipment should be studied

before connecting the equipment to any

primary power supply, in particular the

following sections:

Warnings and Cautions.

Specifications

Electrical and/or Air supply.

Principals of Operation.

Preparation for use.

Regular use.

Regular maintenance.

4. W ith hydraulic tooling, ensure that it is

suitable for use with the Huck Powerig or

Huck approved hand pump being used.

5. Check that the Powerig or approved

hand pump "Pull" and "Return" pressures

have been adjusted to suit the tool being

used. Reference must be made to the

instruction manual supplied with the

equipment.

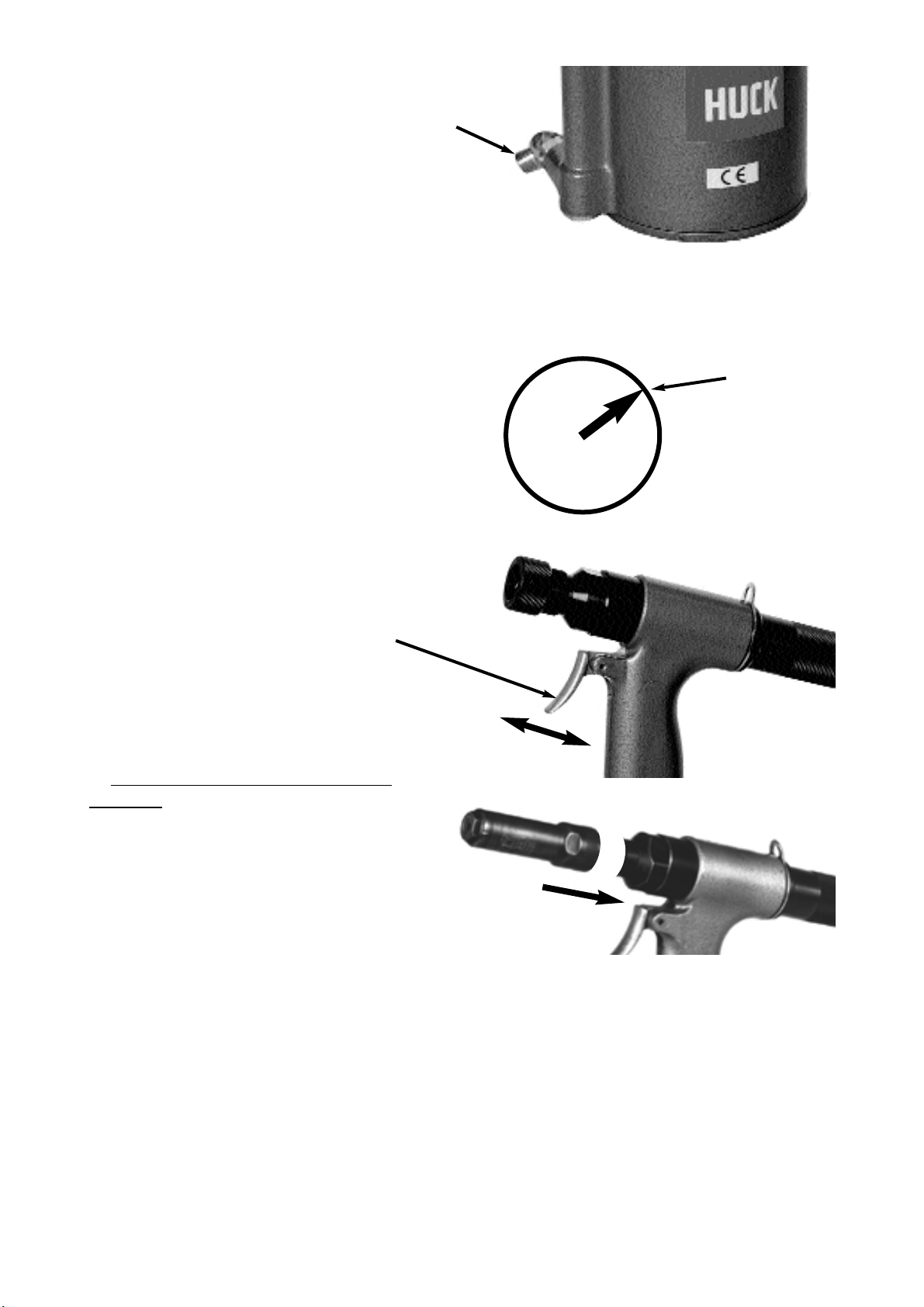

6. Check that the Nose Assembly is of the

correct type suitable for installing the

fastener being used.

7. V isually check all pneumatic and/or

hydraulic hoses, electrical cables,

Powerigs, hand pumps and hand tools, for

any visible signs of damage and leakage.

ALL HYDRAULIC HOSES SHOULD BE

RENEWED EVERY FIVE YEARS.

Huck Fastening Systems

Safety Guidelines when using Huck Installation Equipment to install Huck Fasteners.

8. Do not connect any equipment to

primary power supplies or attempt to use

any equipment, that shows signs of

damage or leakage.

9. Ensure that all air and/or hydraulic hose

and/or electrical plugs/connectors are

correctly connected before switching on

supply to equipment.

When operating the equipment:

10. When using fasteners in some types

of structure, the fracturing of the pintail

during installation may generate noise

levels above the first action level of the

Noise at Work

Regulations and therefore hearing

protection must be worn.

11. It is recommended that eye protection,

(eg. safety glasses), should be worn by

the operator.

12. Never look directly at the front or rear

of the installation tool.

13. Never hold the Installation Tool around

the Nose Assembly.

14. Keep hands/fingers clear of any

moving parts and also apertures in Nose

Assemblies.

15. W arning

Fasteners should only ever be installed in

the actual workpiece to prevent possible

high velocity ejection from the Nose

Assembly due to tensile forces induced

during pintail fracture.

16. When using two piece fasteners, (ie.

Pin and Collar type), the

conical/chamfered end of the collar MUST

always be towards the Nose assembly,

NOT against the work piece.

1