provided with this heater, can result in death, serious bodily injury and

property loss or damage from hazards of fire, explosion, burn,

asphyxiation, carbon monoxide poisoning, and/or electrical shock.

- Only persons who can understand and follow the instructions should

use or service this heater.

- Check the heater thoroughly for damage. DO NOT operate a damaged

heater.

- DO NOT modify the heater or operate a heater which has been modified

from its original condition.

Warning: We recommend the use of a carbon monoxide detector in the

vicinity of the space heater.

Important: Not for domestic use!. Use in open buildings please abide by

the relevant national and local guidelines and regulations.

- For indoor use only. Not for use where exposed to weather.

- Use ONLY in well ventilated areas.

Warning: Fire, burn, inhalation and explosion hazard. Keep solid

combustibles, such as building materials, paper or cardboard, a safe

distance away from the heater. Never use the heater in spaces which do

or may contain volatile or airborne combustibles, or products such as

gasoline, solvents, paint thinner, dust particles or unknown chemicals.

Warning: DO NOT use ducting of any sort with this heater.

Caution: Due to the high surface and exhaust temperatures, adults and

children must observe clearances to avoid burns or clothing ignition. Do

not touch. Keep children, clothing, and combustibles away.

- Never point the heater directly at persons nearby. Install the heater such

that it is not directly exposed to water spray, rain and / or water.

- Never use in areas normally for habitation and /or where children may

be present. Not for domestic use.

- Operate only on a stable, level, flame proof non combustable surface.

- Do not use in a dusty atmosphere. Never restrict or duct inlet or outlet.

- Do not move, handle, or service while the heater is hot or in use.

Gas use safety

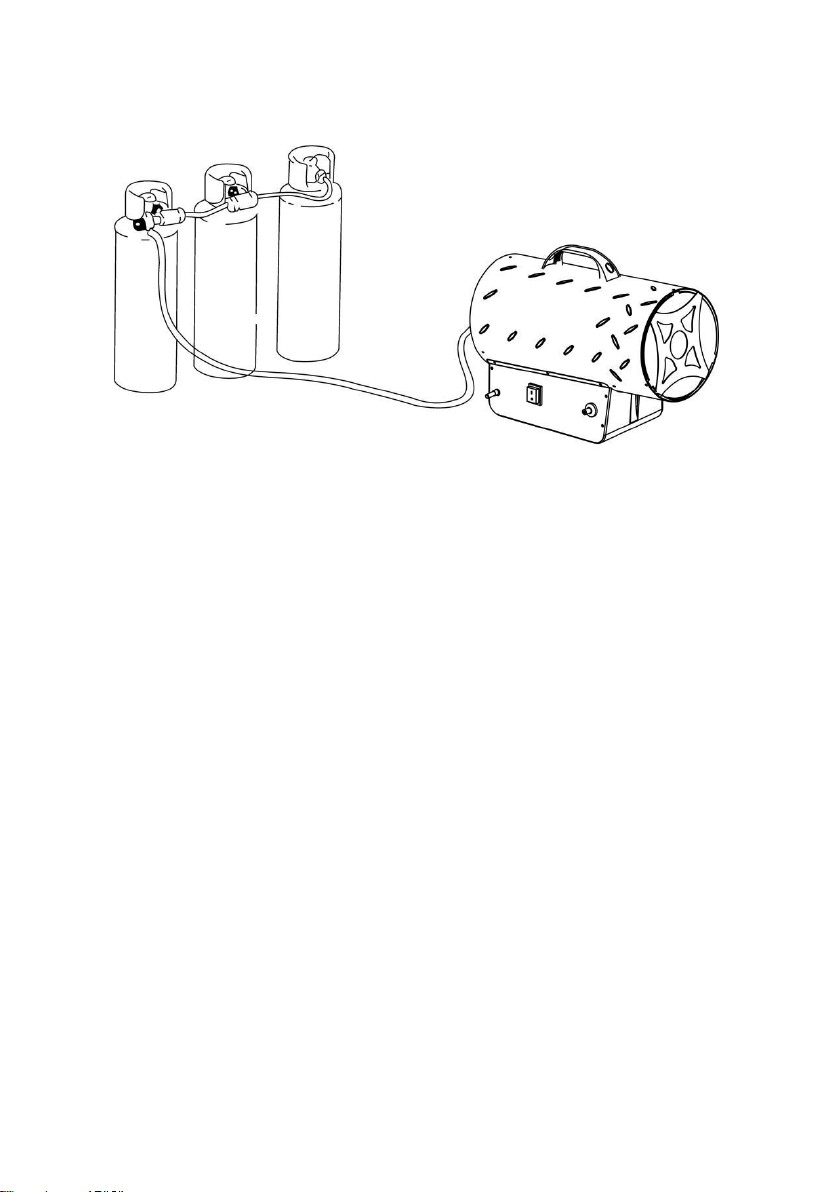

- Gas cylinders must be used and kept in accordance with current

regulations.

- Never direct the hot air flow towards the cylinder.

- Use only the supplied pressure regulator.

- Never use the heater without its cover.

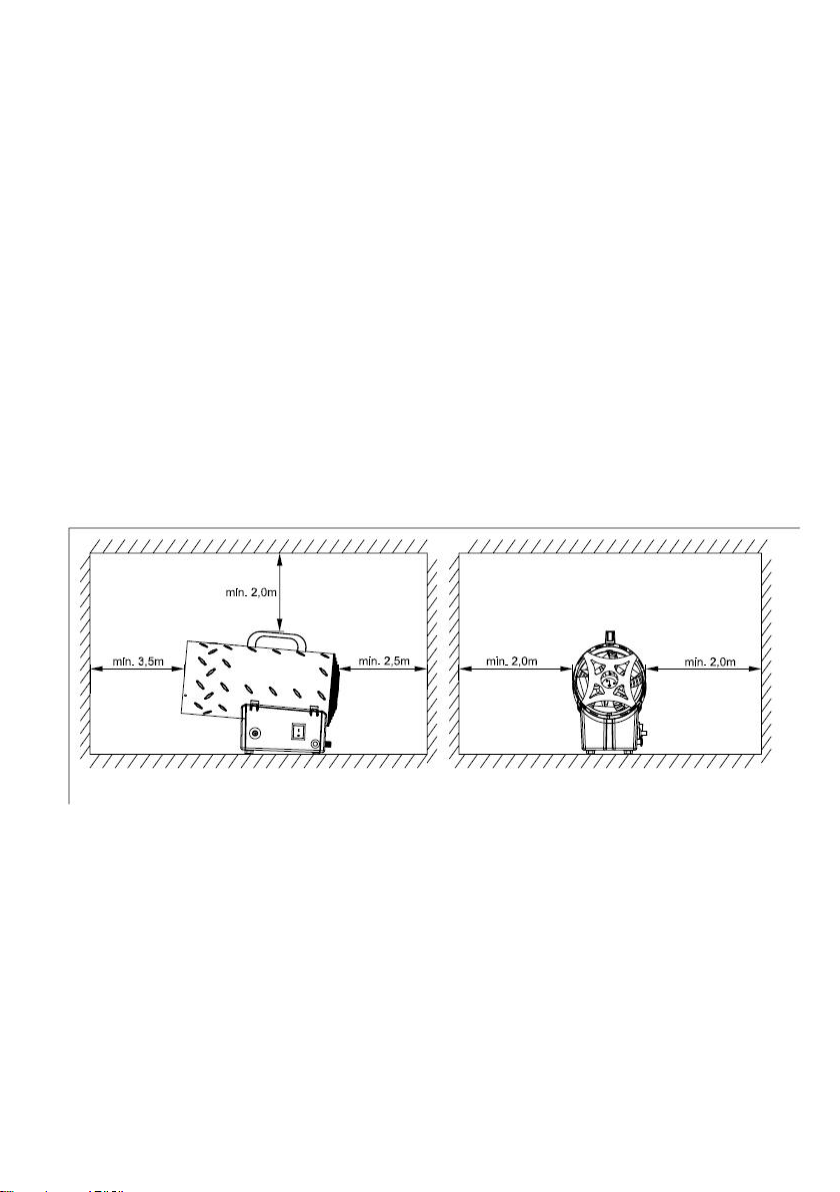

- Do not exceed 100W/m³ of free room. The minimum volume of the room

must be larger than 100m³.

- Do not obstruct the inlet or outlet sections of the heater.

- If the heater has to work for a long period at its maximum capacity, it’s

possible that ice will form on the cylinder. This is due to excessive vapour

withdrawal. Not for this reason, or for any other, should the cylinder be