-7-

and removing the water filters from

the recovery tank (fig. 22), lift up the

lint filter (fig 23), and rinse off both

the lint and primary filter.

4. Cleaning the air filter. To clean

the air filter use your hands to wipe

off any debris. Once or twice a month

the air filter should be removed and

cleaned (fig. 24). To do this remove

the wing nut, nylon washer and middle

brace. Then clean thoroughly and re-

place. Do not operate this machine

without a clean air filter. To do so will

dramatically reduce the life and per-

formance of the vacuum motor.

5. Clean the float switch. First, un-

screw the brass knurl nut (fig.22) and

lift the float switch up. Then spray

out any debris that has built up inside

the float switch with your Dial-a-Mix

sprayer (fig. 25).

6. If it is needed, remove the drain plug

(fig. 26) from the bottom of the recovery

tank and spray out the bottom of the re-

covery tank with the Dial-a-Mix sprayer.

7. If needed remove and clean the

water channel. To do this remove the

two thumb nuts from the underside of

the machine (fig. 29). Lift out the

water channel (fig. 25) and clean.

8. Clean the vacuum shoe and the side

vacuum slots with the lip hook provided

with each machine (fig. 26 and 27).

9. Replace the air filter, float switch,

drain plug, water channel and water

filter. Make sure the water filter sits

flat on the bottom of the recovery tank

and that its garden hose swivel nut is

tightened securely.

10. Clean the exterior of the machine

with a damp cloth and windex.

11. Unscrew the pressure hose (the

red hose) from the sink fitting. Open

then close the pressure valve to release

the water pressure.

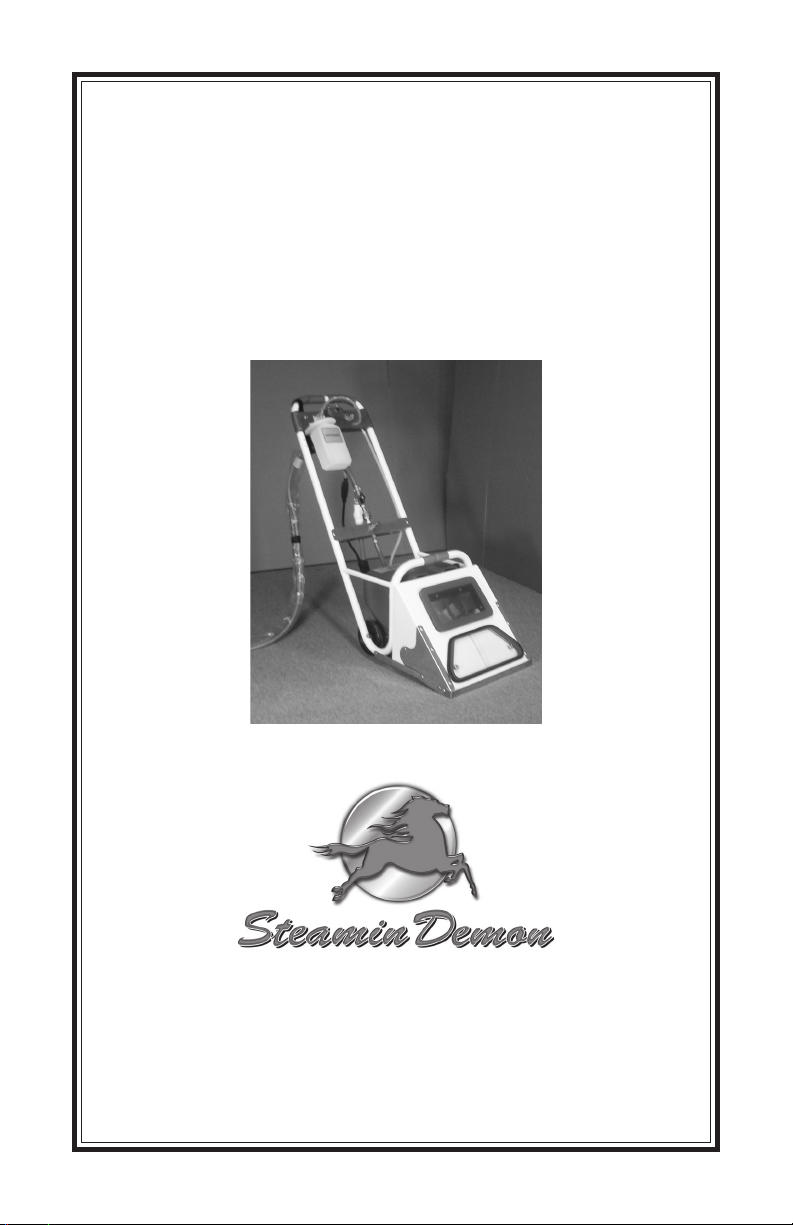

Figure 21: Tilt machine to right to

manually activate discharge pump

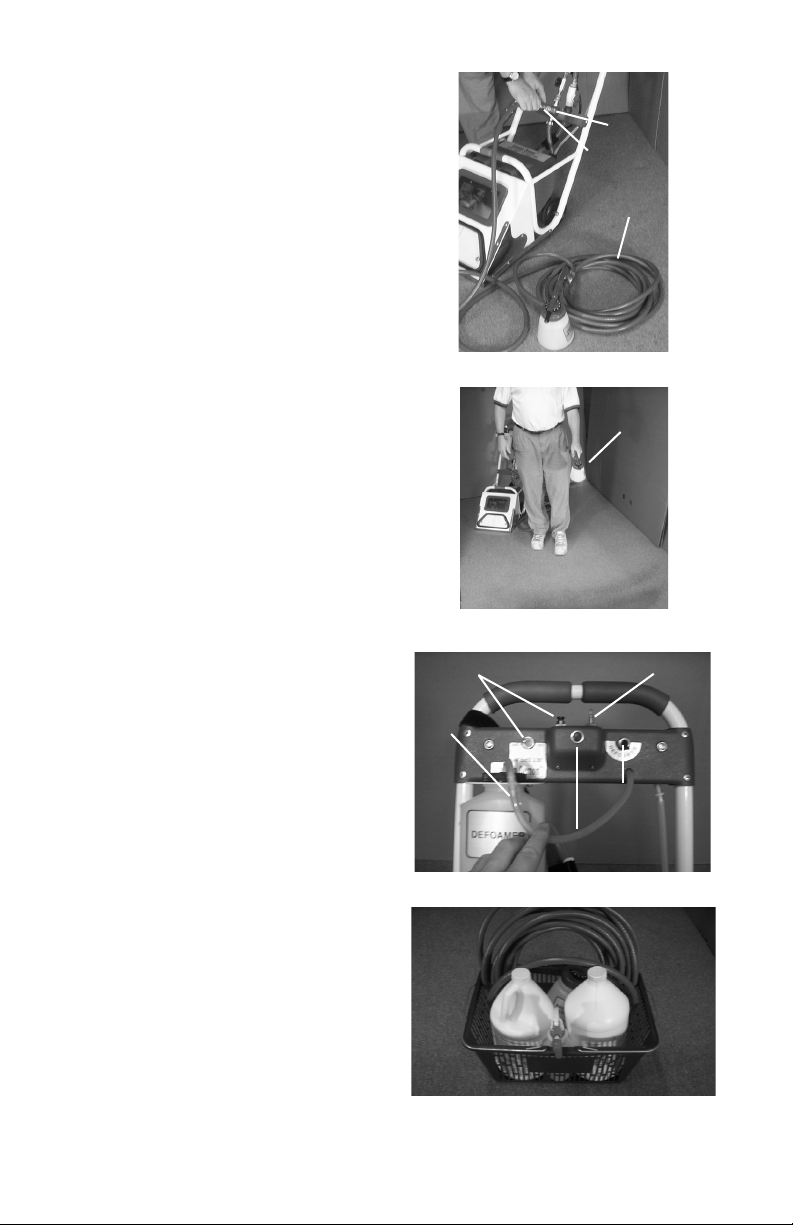

Figure 22: Recovery tank components

that must be cleaned

Water filter swivel nut Air filter

Water filters

Float

switch

Thumb nut

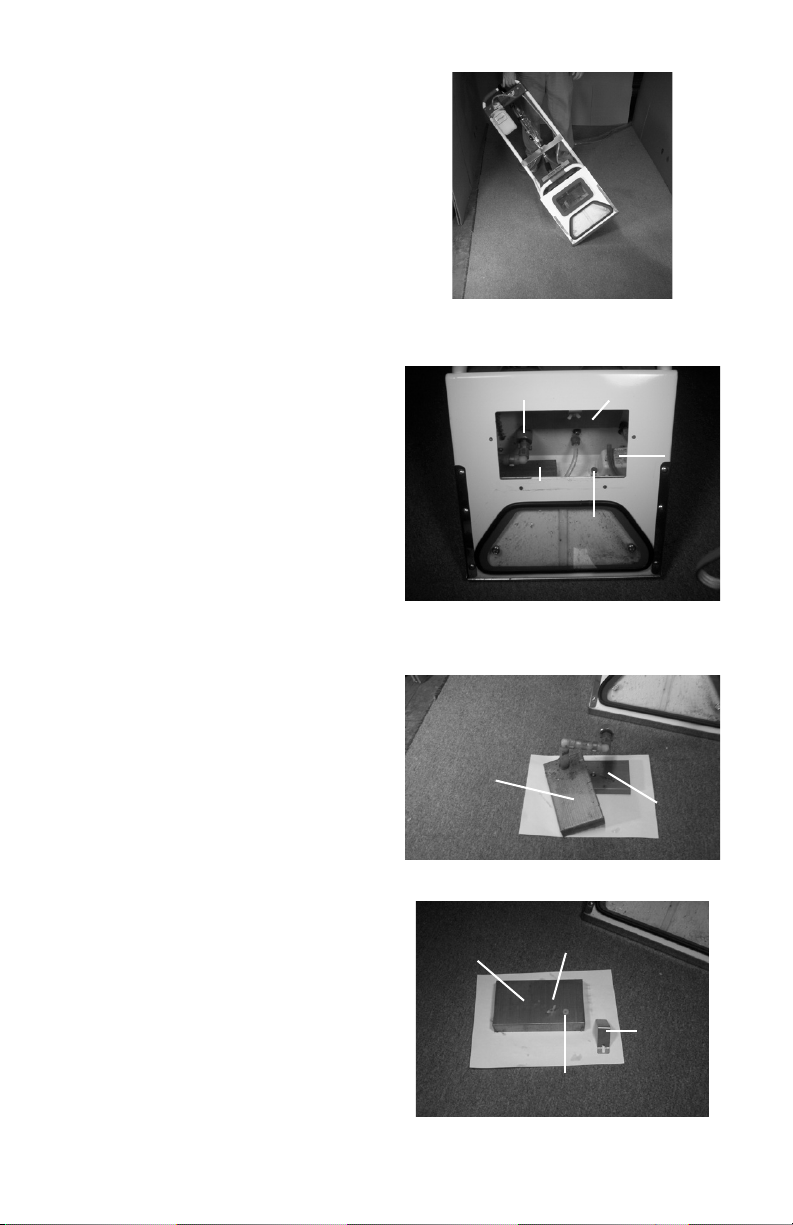

Figure 23: Water filter assembly

Lint filter

Primary

Filter

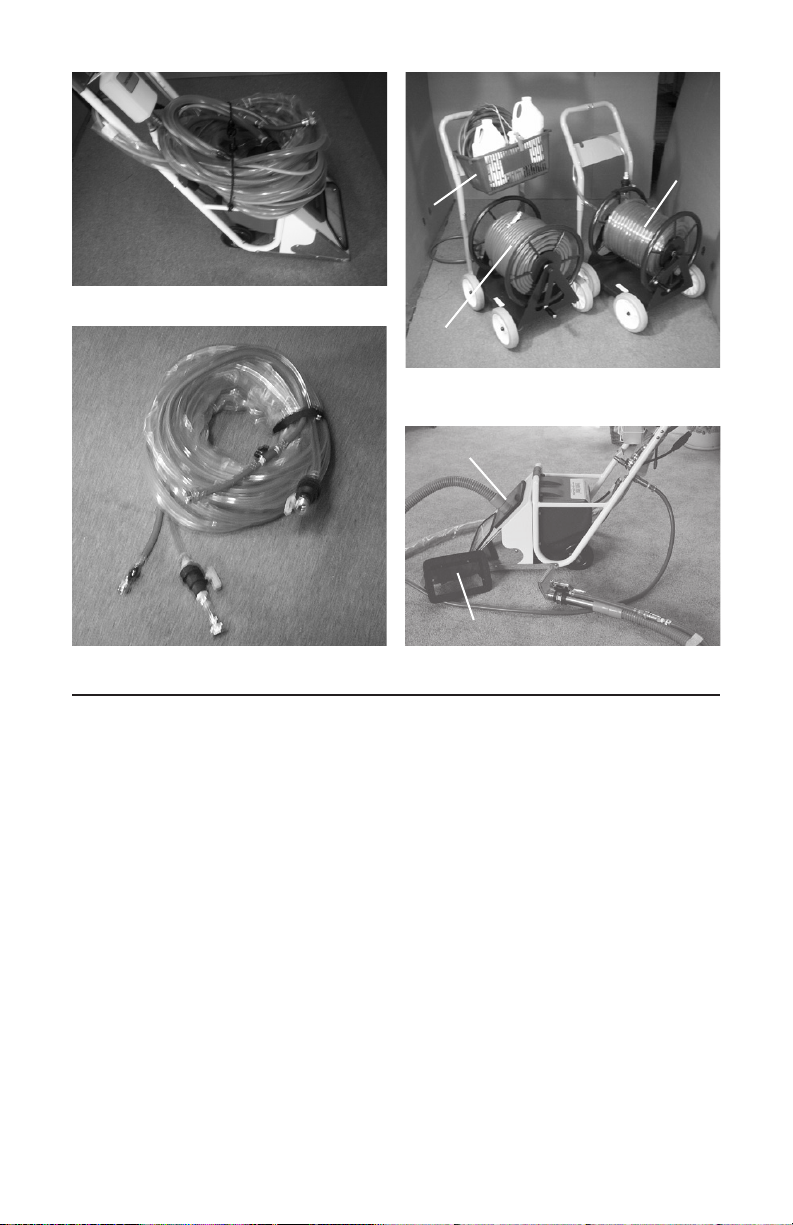

Figure 24: Air filter assembly

Air Filter Nylon wing nut

Nylon washer

Middle

brace