FORM 150.66-NM1 (708)

5

JOHNSON CONTROLS

TABLE OF CONTENTS (CONT’D)

SECTION 4 - INSTALLATION ...........................................................................................................32

INSTALLATION CHECKLIST......................................................................................................................32

HANDLING ..................................................................................................................................................32

INSPECTION ...............................................................................................................................................32

LOCATION AND CLEARANCES................................................................................................................32

Foundation ...........................................................................................................................................33

Ground Level Locations .....................................................................................................................33

Rooftop Locations...............................................................................................................................33

Noise Sensitive Locations ..................................................................................................................33

SPRING ISOLATORS (OPTIONAL)............................................................................................................33

COMPRESSOR MOUNTING ......................................................................................................................33

REMOTE COOLER OPTION ......................................................................................................................33

CHILLED LIQUID PIPING ...........................................................................................................................33

DUCT WORK CONNECTION ....................................................................................................................34

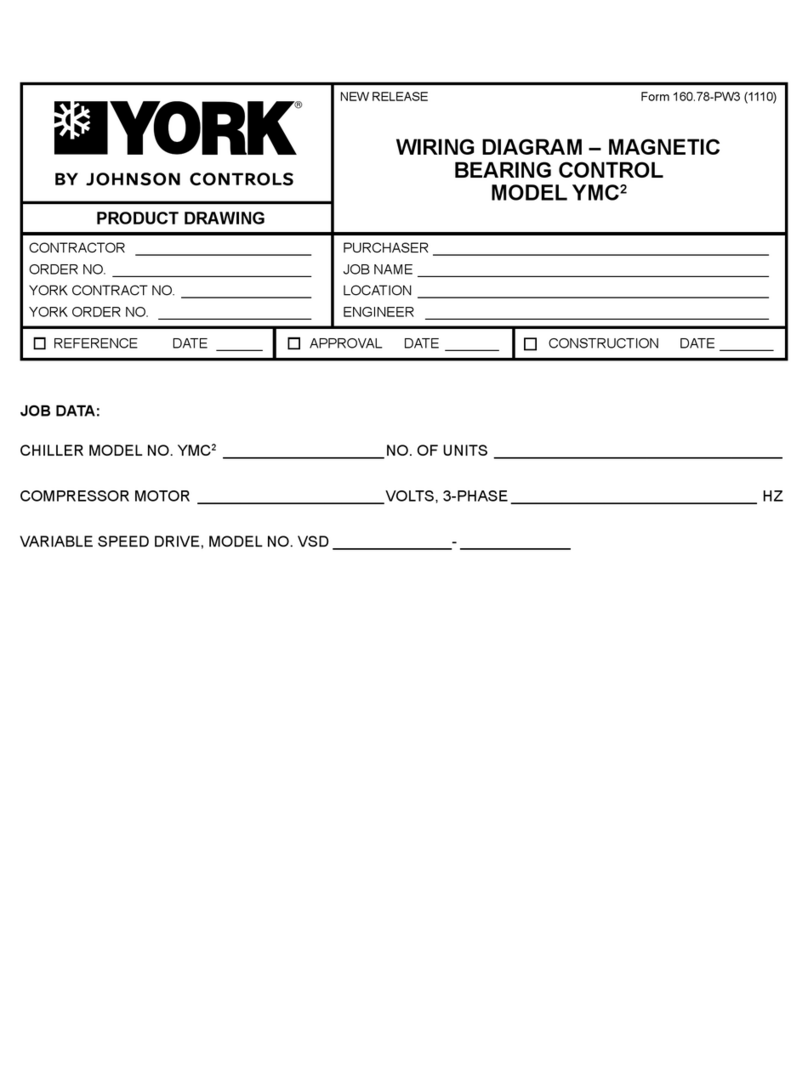

WIRING........................................................................................................................................................34

Evaporator Pump Start Contacts .......................................................................................................35

System Run Contacts .........................................................................................................................35

Alarm Status Contacts ........................................................................................................................35

Remote Start/Stop Contacts...............................................................................................................35

Remote Emergency Cutoff .................................................................................................................35

PWM Input ............................................................................................................................................35

Load Limit Input...................................................................................................................................35

Flow Switch Input ................................................................................................................................35

COMPRESSOR HEATERS .........................................................................................................................35

SINGLE-POINT SUPPLY CONNECTION – TERMINAL BLOCK, NON-FUSED DISCONNECT

SWITCH OR CIRCUIT BREAKER (0041 - 0071) .......................................................................................36

SINGLE-POINT SUPPLY CONNECTION ...................................................................................................36

CONTROL WIRING.....................................................................................................................................37

SECTION 5 - COMMISSIONING .......................................................................................................38

PREPARATION – POWER OFF..................................................................................................................38

Inspection ...........................................................................................................................................38

Refrigerant Charge ..............................................................................................................................38

Service and Oil Line Valves ................................................................................................................38

Compressor Oil....................................................................................................................................38

Fans .....................................................................................................................................................38

Isolation / Protection ...........................................................................................................................38

Control Panel .......................................................................................................................................38

Power Connections .............................................................................................................................38

Grounding ............................................................................................................................................39

Supply Voltage.....................................................................................................................................39

PREPARATION – POWER ON ...................................................................................................................39

Switch Settings....................................................................................................................................39

Compressor Heaters ...........................................................................................................................39

Water System .......................................................................................................................................39

Flow Switch..........................................................................................................................................39

Temperature Sensor(s) .......................................................................................................................39

EQUIPMENT STARTUP CHECKLIST ........................................................................................................40

Checking the System Prior To Initial Start (No Power) ....................................................................40

Compressor Heaters (Power ON – 24 Hours Prior To Start) ...........................................................40

Panel Checks (Power ON – Both Unit Switches OFF)....................................................................40