FORM 160.54-O1

5

JOHNSON CONTROLS

LIST OF FIGURES

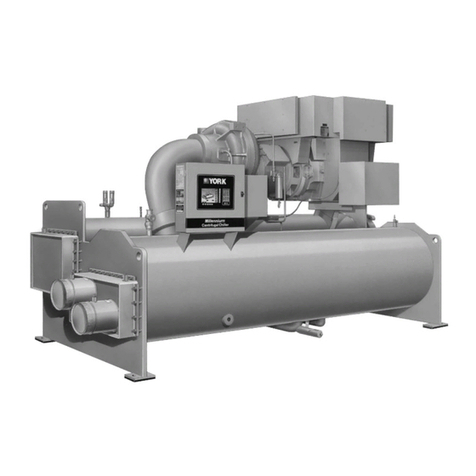

FIG. 1 – MODEL YK MAXE™ CHILLER ............................. 6

DETAIL A – COMPRESSOR PREROTATION

VANES.................................................................. 7

FIG. 2 – REFRIGERANT FLOW-THROUGH CHILLER..... 8

FIG. 3 – OPTIVIEW CONTROL CENTER.........................11

FIG. 4 – HOME SCREEN................................................. 16

FIG. 5 – SYSTEM SCREEN............................................. 19

FIG. 6 – EVAPORATOR SCREEN ................................... 21

FIG. 7 – CONDENSER SCREEN..................................... 24

FIG. 7A – HEAT RECOVERY SCREEN ............................. 26

FIG. 7B – HEAD PRESSURE SCREEN............................. 30

FIG. 8 – REFRIGERANT LEVEL CONTROL SCREEN

(Flash Memory Card version C.MLM.01.06.XXX

and earlier) ......................................................... 32

FIG. 8A – REFRIGERANT LEVEL CONTROL SCREEN

(Software Version C.MLM.01.07.xxx to

C.MLM.01.10D.xxx or C.OPT.01.10D and earlier) .. 34

FIG 8B – REFRIGERANT LEVEL CONTROL SETPOINTS

SCREEN (Software Version C.MLM.01.07.xxx to

C.MLM.01.10D.xxx or C.OPT.01.10D

(and earlier)) ....................................................... 36

FIG 8C – REFRIGERANT LEVEL CONTROL SCREEN

(Software version C.MLM.01.14.xxx (and later) or

C.OPT.01.14.306 (and later)) ............................. 38

FIG. 9 – COMPRESSOR SCREEN

(All “P” Compressors and Style F chillers with

G, Q or H5-8 compressors) ................................ 40

FIG. 9A – COMPRESSOR SCREEN (Style E and earlier

chillers with G, H or J compressors and Style F

and later chillers with J or H3 compressors)....... 42

FIG. 10 – PROXIMITY PROBE CALIBRATION SCREEN

(Style E and earlier chillers with G, H and J

compressors and Style F and later chillers with

J or H3 compressors) ......................................... 44

FIG. 11 – HOT GAS BYPASS SCREEN ............................ 46

FIG. 12 – SURGE PROTECTION SCREEN ...................... 48

FIG. 12A – VARIABLE GEOMETRY DIFFUSER SCREEN.. 52

FIG. 12B – VARIABLE GEOMETRY DIFFUSER SETPOINTS

SCREEN............................................................. 54

FIG. 13 – PRE-ROTATION VANES CALIBRATION

SCREEN............................................................. 56

FIG. 14 – VSD TUNING SCREEN ..................................... 58

FIG. 15 – OIL SUMP SCREEN........................................... 60

FIG. 16 – ELECTRO-MECHANICAL STARTER SCREEN.... 64

FIG. 17 – MOD “A” SOLID STATE STARTER SCREEN .... 66

FIG. 18 – MOD “B” SOLID STATE STARTER SCREEN .... 68

FIG. 18A – MEDIUM VOLTAGE SOLID STATE STARTER

SCREEN............................................................. 70

FIG. 19 – VARIABLE SPEED DRIVE SCREEN ................. 72

FIG. 19A – MEDIUM VOLTAGE VARIABLE SPEED DRIVE

SCREEN (Software Version C.OPT.01.16.xxx

and Later) ........................................................... 74

FIG. 20 – VARIABLE SPEED DRIVE DETAILS SCREEN

(Style D VSD and VSD with part number

371-03789-xxx (503 HP 60 Hz; 419 HP 50 Hz).. 78

FIG. 21 – VARIABLE SPEED DRIVE DETAILS SCREEN

(VSD with Part Number 371-02767-XXX

(60 Hz) or 371-03700-XXX (50 HZ))................... 80

FIG. 22 – ADAPTIVE CAPACITY CONTROL SCREEN

(software version C.OPT.01.18.307 and earlier) 82

FIG. 22A – ADAPTIVE CAPACITY CONTROL SCREEN

(YORK protocol conguration)

(software version C.OPT.01.19.307 and later) ... 84

FIG. 22B – ADAPTIVE CAPACITY CONTROL SCREEN

(Modbus protocol conguration)

(software version C.OPT.01.19.307 and later) ... 86

FIG. 22C – SURGE MAP SCREEN - TABLE VIEW

(software version C.OPT.01.19.307 and later) ... 90

FIG. 22D – SURGE MAP SCREEN - LIST VIEW

(software version C.OPT.01.19.307 and Later) .. 92

FIG. 23 – HARMONIC FILTER DETAILS SCREEN

(Style D VSD and VSD with part number

371-03789-xxx (503 HP 60 Hz; 419 HP 50 Hz).. 94

FIG. 24 – HARMONIC FILTER DETAILS SCREEN

(VSD with Part Number 371-02767-XXX (60 Hz)

or 371-03700-XXX (50 Hz)) ............................... 96

FIG. 25 – MOTOR LUBRICATION SCREEN (Software version

C.MLM.01.14.xxx (and later) or C.OPT.01.14.306

(and later)) .......................................................... 98

FIG. 26 – SETPOINTS SCREEN ..................................... 100

FIG. 27 – SETUP SCREEN.............................................. 104

FIG. 27A – QUICK START SCREEN.................................. 108

FIG. 28 – SCHEDULE SCREEN .......................................112

FIG. 29 – USER SCREEN.................................................114

FIG. 30 – COMMS SCREEN.............................................116

FIG. 31 – PRINTER SCREEN...........................................118

FIG. 32 – SALES ORDER SCREEN ................................ 120

FIG. 33 – OPERATIONS SCREEN .................................. 122

FIG. 34 – HISTORY SCREEN.......................................... 124

FIG. 35 – HISTORY DETAILS SCREEN .......................... 126

FIG. 36 – SECURITY LOG SCREEN............................... 127

FIG. 37 – SECURITY LOG DETAILS SCREEN ............... 128

FIG. 38 – CUSTOM VIEW SCREEN................................ 129

FIG. 39 – CUSTOM VIEW SETUP SCREEN

................... 130

FIG. 40 – TREND SCREEN ............................................. 132

FIG. 41 – TREND SETUP SCREEN ................................ 134

FIG. 42 – ADVANCED TREND SETUP SCREEN............ 136

FIG. 43 – COMMON SLOTS SCREEN ............................ 138

FIG. 44 – PRINTERS ....................................................... 164

FIG. 45 – SAMPLE PRINTOUT (STATUS)....................... 170

FIG. 46 – SAMPLE PRINTOUT (SETPOINTS)................ 172

FIG. 47 – SAMPLE PRINTOUT (SCHEDULE)................. 174

FIG. 48 – SAMPLE PRINTOUT (SALES ORDER)........... 175

FIG. 49 – SAMPLE PRINTOUT (HISTORY) .................... 176

FIG. 50 – SAMPLE PRINTOUT (SECURITY LOG).......... 178

FIG. 51 – SAMPLE PRINTOUT (TREND)........................ 178

FIG. 52 – SAMPLE PRINTOUT – (CUSTOM SCREEN).. 179

FIG. 53 – SAMPLE PRINTOUT – (ADAPTIVE CAPACITY

CONTROL NEW MAP POINT)......................... 179

FIG. 54 – SAMPLE PRINTOUT (ADAPTIVE CAPACITY

CONTROL EXISTING MAP POINTS) .............. 179