Johnson Controls EDA-8102 User manual

Other Johnson Controls Controllers manuals

Johnson Controls

Johnson Controls VMA1615 User manual

Johnson Controls

Johnson Controls VA9208-AG Series User manual

Johnson Controls

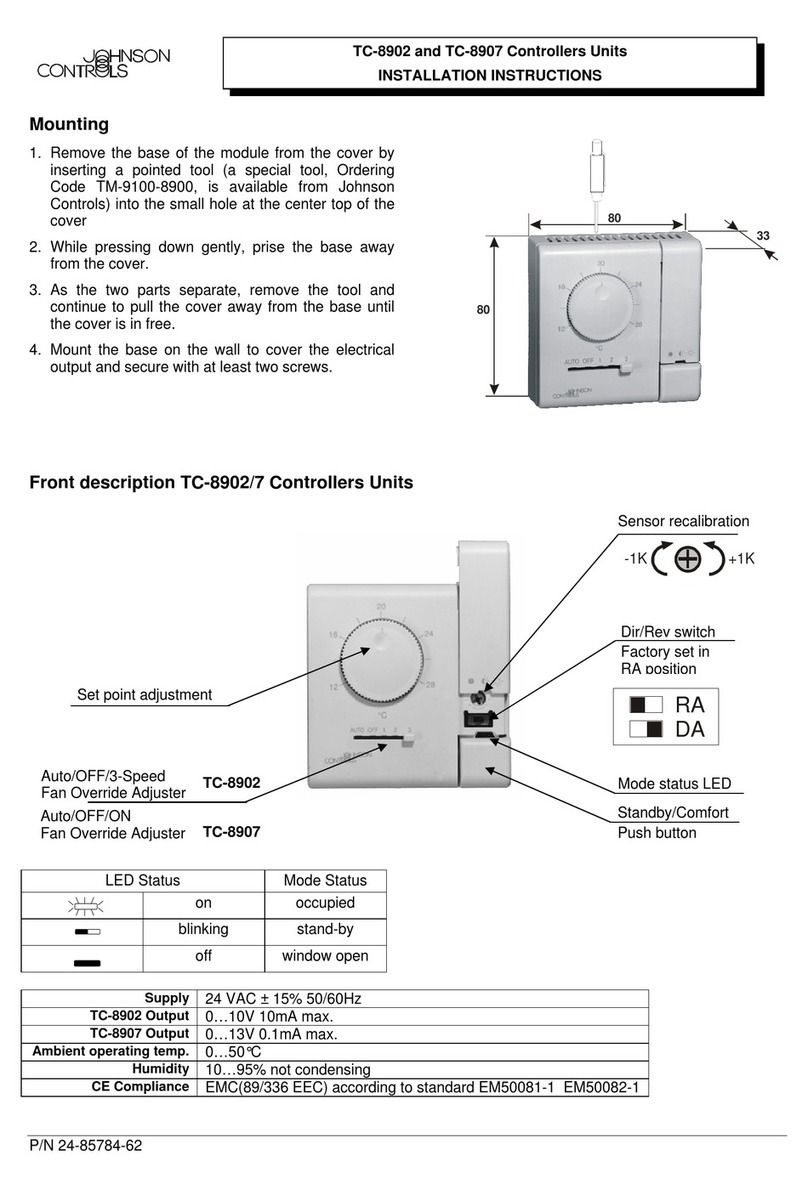

Johnson Controls TC-8902 User manual

Johnson Controls

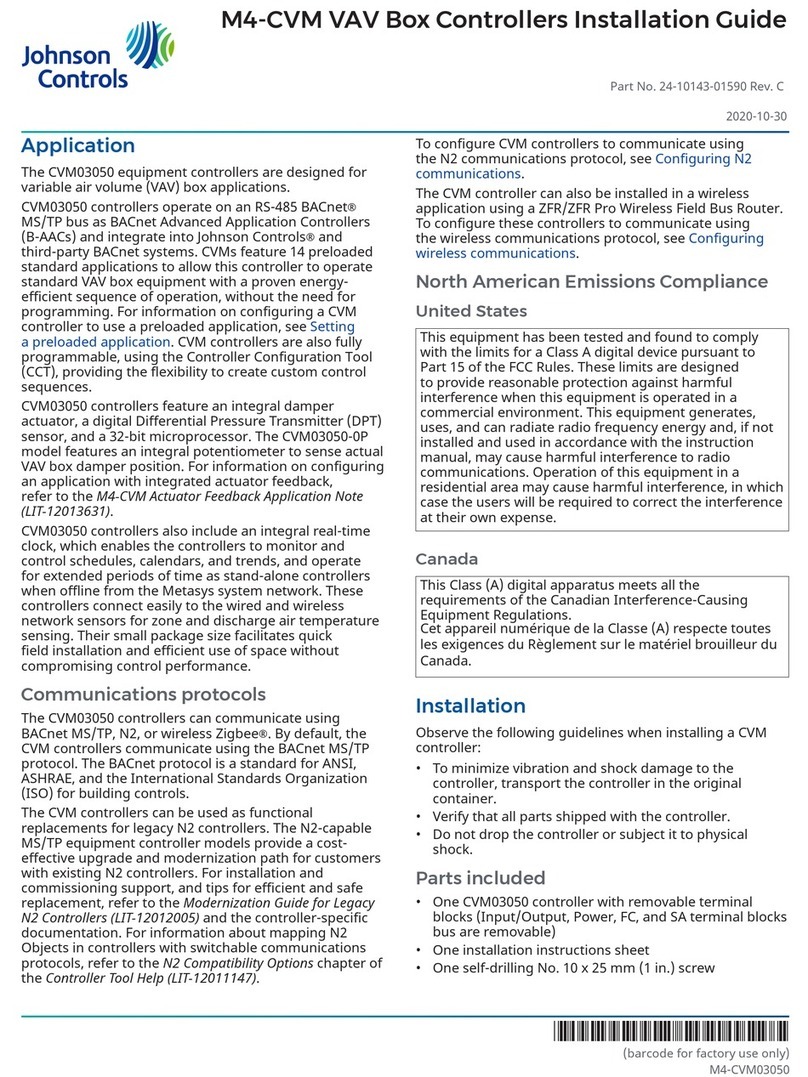

Johnson Controls CVM03050 User manual

Johnson Controls

Johnson Controls S1-33103010000 User manual

Johnson Controls

Johnson Controls FEC26 Series User manual

Johnson Controls

Johnson Controls VAP Series User manual

Johnson Controls

Johnson Controls PENN P70 Series User manual

Johnson Controls

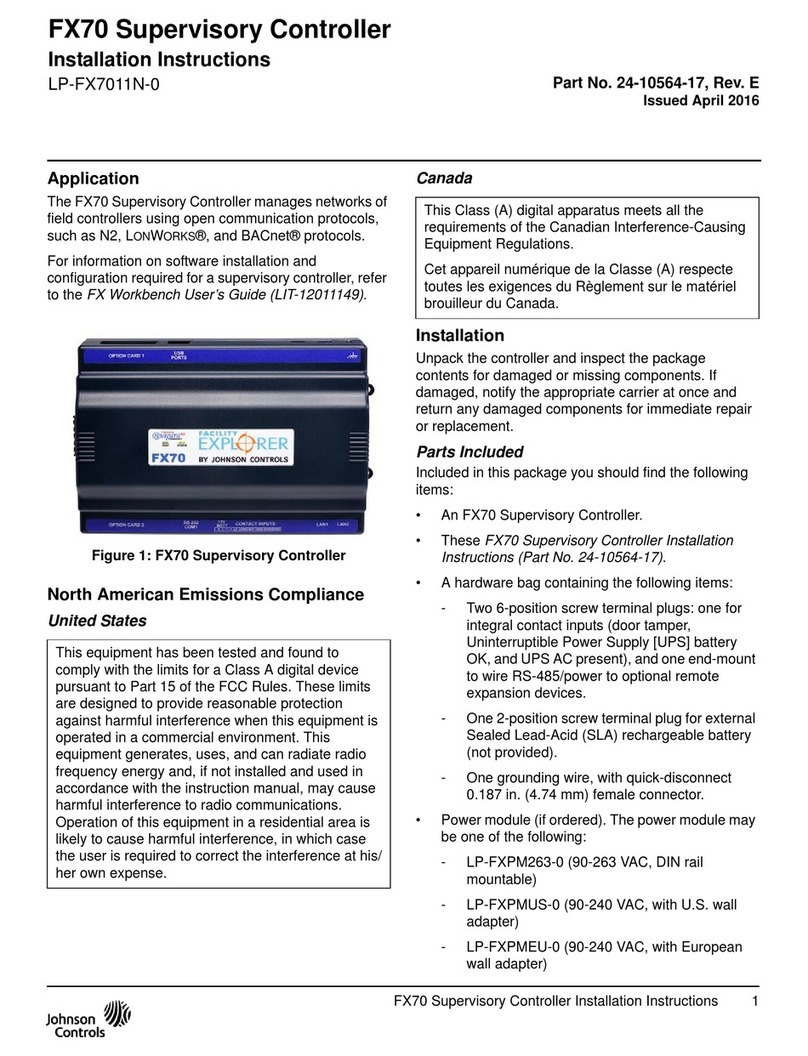

Johnson Controls FX70 User manual

Johnson Controls

Johnson Controls PENN ACT2 Service manual

Johnson Controls

Johnson Controls DS-3153 User manual

Johnson Controls

Johnson Controls VMA1615 User manual

Johnson Controls

Johnson Controls F4-CG Series User manual

Johnson Controls

Johnson Controls VA9104-AGA-1S User manual

Johnson Controls

Johnson Controls CK721-A User manual

Johnson Controls

Johnson Controls TEC3000 Series User manual

Johnson Controls

Johnson Controls FX-PCA3611 User manual

Johnson Controls

Johnson Controls VA7820-GG-1 Series User manual

Johnson Controls

Johnson Controls VA-77 Series User manual

Johnson Controls

Johnson Controls M4-CGM Series User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions