Johnson Controls EDA-2040 User manual

Other Johnson Controls Controllers manuals

Johnson Controls

Johnson Controls VA-7700 Series User manual

Johnson Controls

Johnson Controls VMA1200 Series User manual

Johnson Controls

Johnson Controls Metasys VMA1610 User manual

Johnson Controls

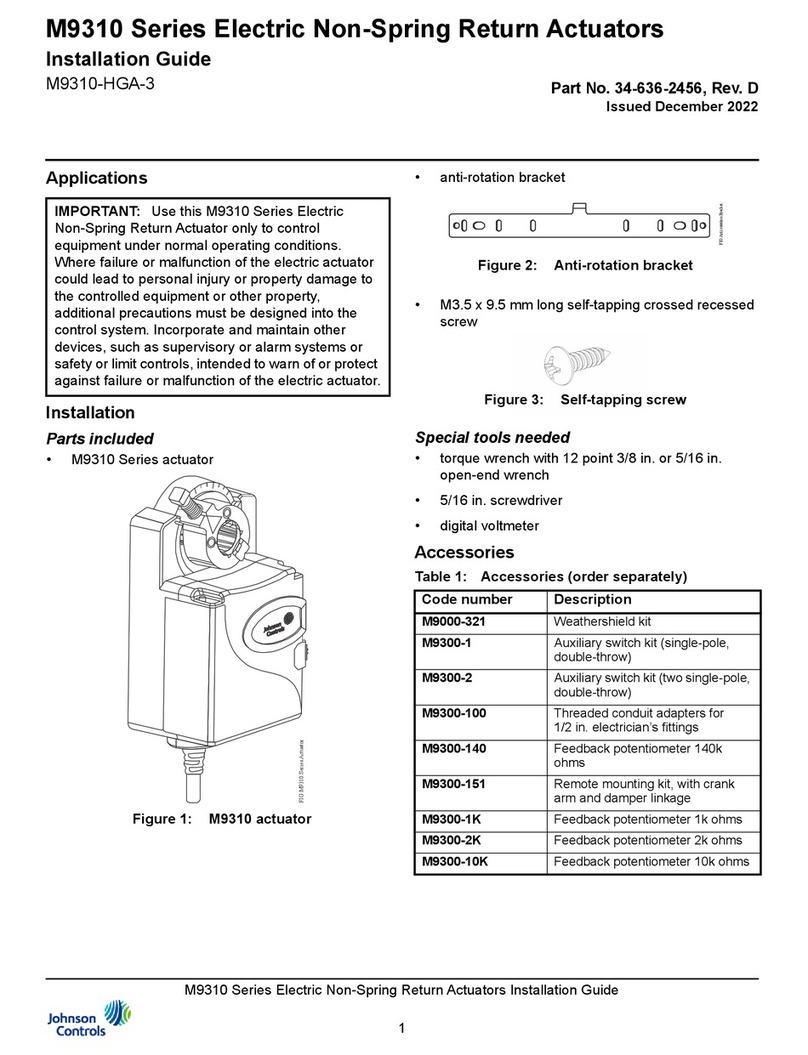

Johnson Controls M9310-HGA-3 User manual

Johnson Controls

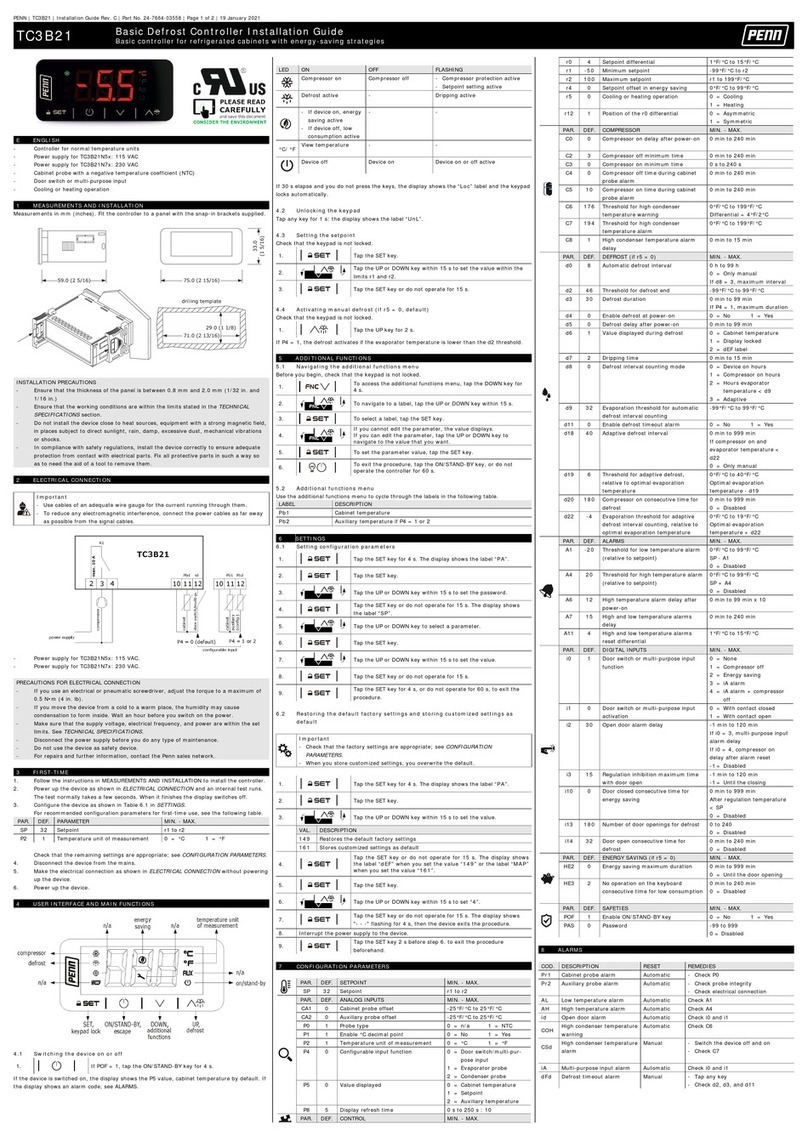

Johnson Controls penn TC3B21 User manual

Johnson Controls

Johnson Controls VA-7481-0011 User manual

Johnson Controls

Johnson Controls VFD66 Series Manual

Johnson Controls

Johnson Controls tyco Power Neo HS2016 User manual

Johnson Controls

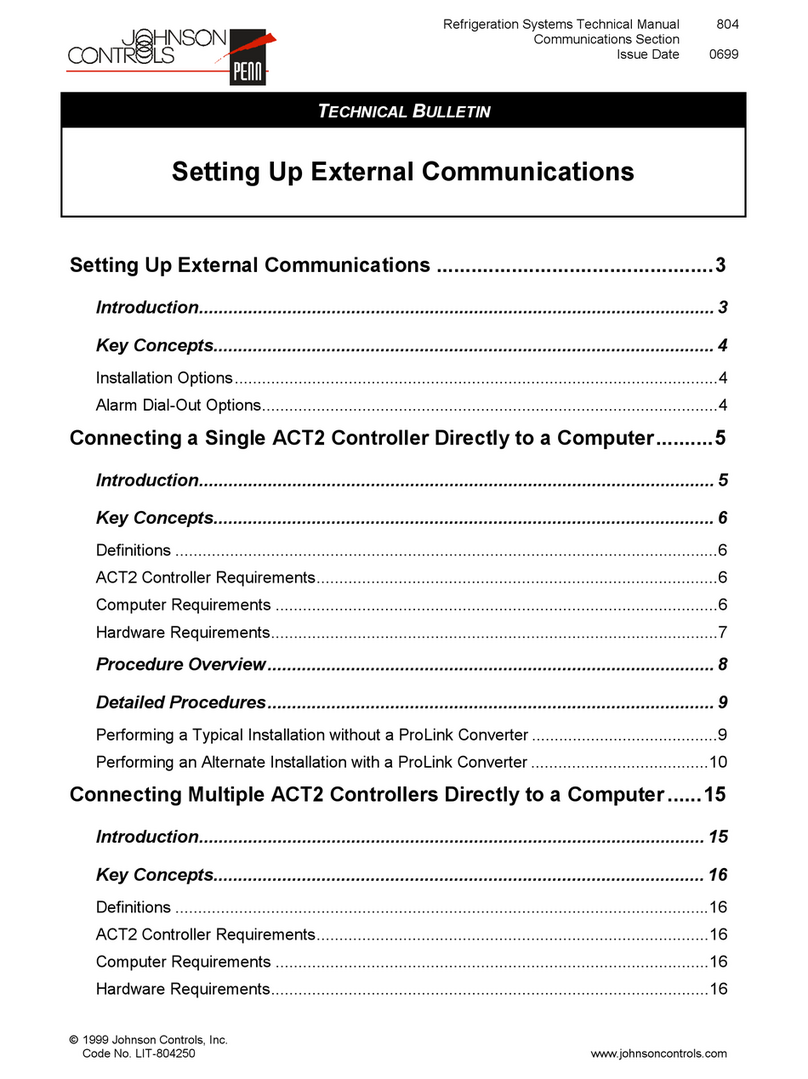

Johnson Controls PENN ACT2 Service manual

Johnson Controls

Johnson Controls Penn P216 User manual

Johnson Controls

Johnson Controls P266 Series User manual

Johnson Controls

Johnson Controls VA9300 User manual

Johnson Controls

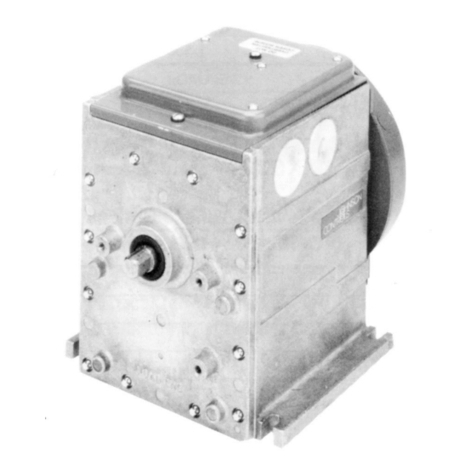

Johnson Controls VA-9070 Series Service manual

Johnson Controls

Johnson Controls M100C Series User manual

Johnson Controls

Johnson Controls CK721-A Quick start guide

Johnson Controls

Johnson Controls FX-PCV Series User manual

Johnson Controls

Johnson Controls DWCR2 User manual

Johnson Controls

Johnson Controls tyco Kantech IP LINK User manual

Johnson Controls

Johnson Controls FX-PCV1656 User manual

Johnson Controls

Johnson Controls VA9208-AG Series User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions