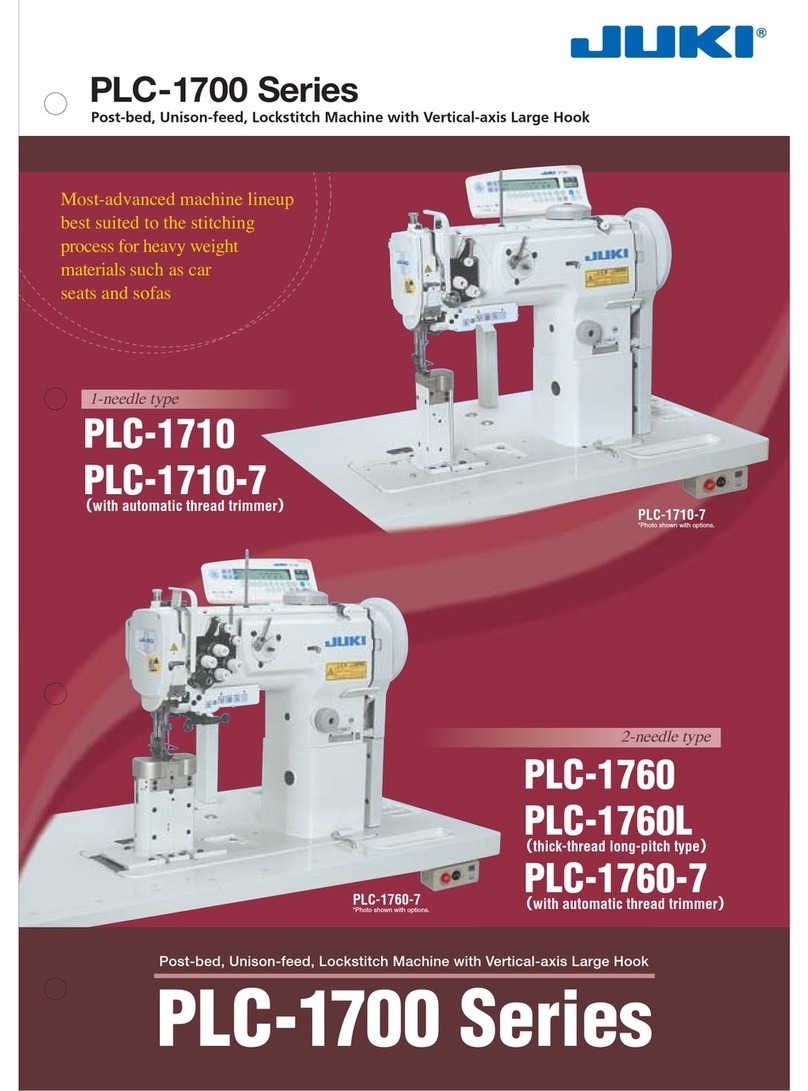

This newest and most advanced machine has been developed in the pursuit of upgraded seam

quality and improved workability in bottom hemming processes.

The machine offers excellent seam quality

and sewing capabilities.

Efficient workability.

●The needle bar stroke is as high as 35mm. This offers

increased penetration of the needle into the material to

improve adaptability to heavy-weight materials.

●The machine demonstrates excellent sewing capabilities,

when sewing heavy-weight denim or multi-layered

portions, that free it of sewing troubles such as stitch

gathering, stitch skipping and needle breakage.

●The machine is able to sew material with a low presser

foot pressure while preventing the material from flapping.

As a result, the material can be sewn free of puckering.

●The top- and bottom-roller style feed mechanism forms

seams with increased consistency to achieve improved

hemming quality while reducing uneven hems.

Highly consistent and reliable thread

trimmer mechanism.

●The machine employs a highly reliable horizontal

thread trimming mechanism which cuts thick

thread without fail.

●The entire knife unit can be installed/removed.

●The moving knife position can be easily adjusted.

●The knife unit is of a bed device type. This means

that adjustment of the knife unit is not required

after removing the throat plate.

●Every time that operation of the thread trimmer

occurs, the air blower keeps the knife clean by

blowing off thread chips from the blade, ensuring

the reliable operation of the thread trimmer.

●The machine has adopted a forced circulation mechanism in

consideration of reliable oiling and oil leakage prevention.

●The frame and cylinder-bed sections are provided with a circulation

feature to prevent oil leakage. In addition, to ensure reliable operation,

a gasket is fitted inside the frame, preventing any leakage of oil from

the needle bar.

●The machine comes with a newly designed needle bar sliding

mechanism that is highly durable and free of play.

●Coupled to the automatic presser lifter, the hemming binder

automatically opens/closes. This enables efficient operation.

●The binder can be adjusted both longitudinally and laterally.

●The binder can also be independently opened/closed by

operating the knee switch (knee lifter for machines without

a thread trimmer).

The lubrication mechanism effectively reduces oil stains

on the material.

Feed rollers, pressers, feed adjusting gears and binders from the UNION SPECIAL 63900 model machine can be

attached to the DLN-6390/-6390-7 with no additional machining or adjustments.

Parts from your current machine are also compatible with the DLN-6390/-6390-7.

●The machine is provided with a 1.7-fold hook,

which demonstrates remarkable productivity.

●The needle feed amount can be easily adjusted

with the scale dial, so as to get the best suited

seam quality when the material or thread is

changed.

✽ For machines DLN-6390 that are not provided with a thread trimmer,

the binder can be opened/closed simultaneously with the presser lifting

action by means of the knee lifter supplied with the machine.

Knee lifter (Part No.: 400-04417)

Presser foot

1/2" Part No.: 300-31108

Binder

1/2" Part No.: 300-15309

Feed roller

1/2" Part No.: 276-38006 (Top roller)

1/2" Part No.: 276-35705 (Bottom roller)

The shaded portion indicates the factory-attached gear present at the time of

delivery. It can be interchanged with other gears supplied with the machine to

support four different feed amounts.

Top g e ar Bottom gear

Feed pitch

JUKI part No. Engraved marker JUKI part No. Engraved marker

Remarks

4.2mm (6 stitch/inch) 300-37600 63949-47 300-37501 63949-33 Option

3.6mm (7 stitch/inch) 300-37303 63949-44 300-37402 63949-36 Supported by the gear supplied

with the machine.

3.2mm (8 stitch/inch) 300-33302 63949-41 300-33203 63949-39 Standard factory-attached gear

present at the time of delivery

2.8mm (9 stitch/inch) 300-33203 63949-39 300-33302 63949-41 Supported by changing over the

factory-attached top and bottom gears.

2.5mm (10 stitch/inch) 300-33104 63949-37 300-33401 63949-43 Option

2.3mm (11 stitch/inch) 300-37402 63949-36 300-37303 63949-44 Supported by the gear supplied

with the machine.

2.1mm (12 stitch/inch) 300-37501 63949-33 300-37600 63949-47 Option

■Parts provided as standard

■Options

■Table of feed amount adjustment/conversion gears

Hem width 3/8"

Part No.: 300-31009

Hem width 1"

Part No.: 277-94601

Hem width 1" (asm.)

Part No.: 400-10327

1/2" roller (knurled type)

Part No.: 300-20705 (Top roller)

Part No.: 300-32106 (Bottom roller)

1" roller (knurled type)

Part No.: 277-94403 (Top roller)

Part No.: 277-94502 (Bottom roller)

DLN-6390-7