(1) To continue performing sewing from some point in sewing ......................................................... 37

(2) To perform re-sewing from the start.............................................................................................38

2-10. When setting of sewing product is difcult because of interruption of needle tip .................... 39

2-11. Winding bobbin thread ...............................................................................................................40

(1) When performing winding bobbin thread while performing sewing ............................................. 40

(2) When performing winding bobbin thread only ............................................................................. 40

2-12. Using counter..............................................................................................................................41

(1) Setting procedure of the counter .................................................................................................41

(2) Count-up releasing procedure .....................................................................................................43

(3) How to change the counter value during sewing .........................................................................43

2-13. Performing new register of users’ pattern................................................................................44

2-14. Naming users’ pattern ................................................................................................................45

2-15. Performing new register of pattern button............................................................................... 46

2-16. LCD display section at the time of pattern button selection ..................................................47

(1) Pattern button data input screen.................................................................................................. 47

(2) Sewing screen .............................................................................................................................49

2-17. Performing pattern button No. selection .................................................................................. 51

(1) Selection from the data input screen ...........................................................................................51

(2) Selection by means of the shortcut button................................................................................... 52

2-18. Changing contents of pattern button........................................................................................53

2-19. Copying pattern button ..............................................................................................................54

2-20. Changing sewing mode..............................................................................................................55

2-21. LCD display section at the time of combination sewing.........................................................56

(1) Pattern input screen..................................................................................................................... 56

(2) Sewing screen .............................................................................................................................58

2-22. Performing combination sewing ...............................................................................................60

(1) Selection of combination data...................................................................................................... 60

(2) Creating procedure of the combination data................................................................................ 61

(3) Deleting procedure of the combination data ................................................................................62

(4) Deleting procedure of the step of the combination data .............................................................. 62

2-23. Using the simple operation mode ............................................................................................. 63

2-24. LCD display when the simple operation is selected................................................................64

(1) Data input screen (individual sewing) ..........................................................................................64

(2) Sewing screen (individual sewing)...............................................................................................67

(3) Data input screen (combination sewing)...................................................................................... 70

(4) Sewing screen (combination sewing) ..........................................................................................72

2-25. Changing memory switch data..................................................................................................74

2-26. Using information .......................................................................................................................75

(1) Observing the maintenance and inspection information.............................................................. 75

(2) Releasing procedure of the warning ............................................................................................76

2-27. Using communication function .................................................................................................77

(1) Handling possible data ................................................................................................................77

(2) Performing communication by using the media........................................................................... 77

(3) Performing communication by using USB ...................................................................................77

(4) Take-in of the data ....................................................................................................................... 78

(5) Taking in plural data together....................................................................................................... 79

2-28. Performing formatting of the media.......................................................................................... 81

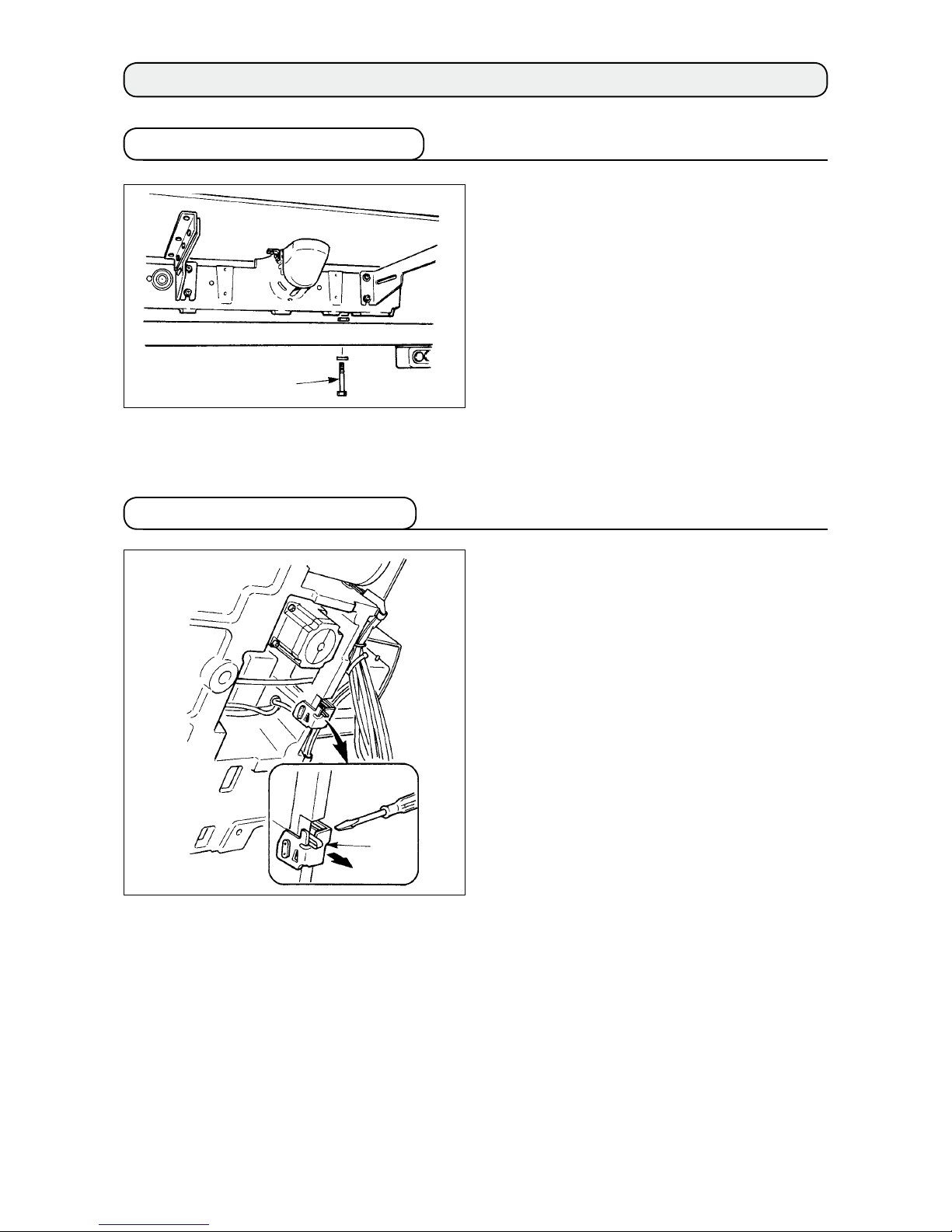

2-29. Operation at the time of X/Y motor position slip......................................................................82

(1) When the error is displayed during sewing.................................................................................. 82

(2) When the error is displayed after end of sewing.......................................................................... 83

(3) When the rest switch is not displayed.......................................................................................... 83