(1) Initial sewing data at the time of your purchase .....................................................@- 36

(2) Changing procedure of sewing data ........................................................................@- 37

(3) Sewing data list ..........................................................................................................@- 38

21. PERFORMING NEW REGISTRATION OF THE PATTERN ......................@- 42

22. COPYING SEWING PATTERN ..................................................................@- 43

23. PERFORMING CHUCK ADJUSTMENT....................................................@- 45

24. PERFORMING BUTTON CENTERING .....................................................@- 46

25.

PERFORMING INPUT AND CHECK OF DATA WITH STEP MOTION ......

@-

47

(1) Performing the step motion.......................................................................................@- 47

(2) Data list........................................................................................................................@- 50

26. PERFORMING COMPENSATION OF UNEVENNESS OF BUTTON .......@- 52

27. CHANGING SEWING MODE.....................................................................@- 53

28. LCD DISPLAY SECTION AT THE TIME OF CYCLE STITCHING ............@- 54

(1) Data input screen .......................................................................................................@- 54

(2) Sewing screen ............................................................................................................@- 56

29. PERFORMING CYCLE STITCHING..........................................................@- 58

(1) Selection of the cycle data ........................................................................................@- 58

(2) Editing procedure of the cycle data..........................................................................@- 59

30. PERFORMING CHANGE OF DISPLAY OF SEWING PRODUCT............@- 61

31. USING COUNTER .....................................................................................@- 62

(1) Setting procedure of the counter..............................................................................@- 62

(2) Count-up releasing procedure ..................................................................................@- 64

32. CHANGING MEMORY SWITCH DATA .....................................................@- 64

(1) Changing procedure of memory switch data ..........................................................@- 64

(2) Memory switch data list .............................................................................................@- 66

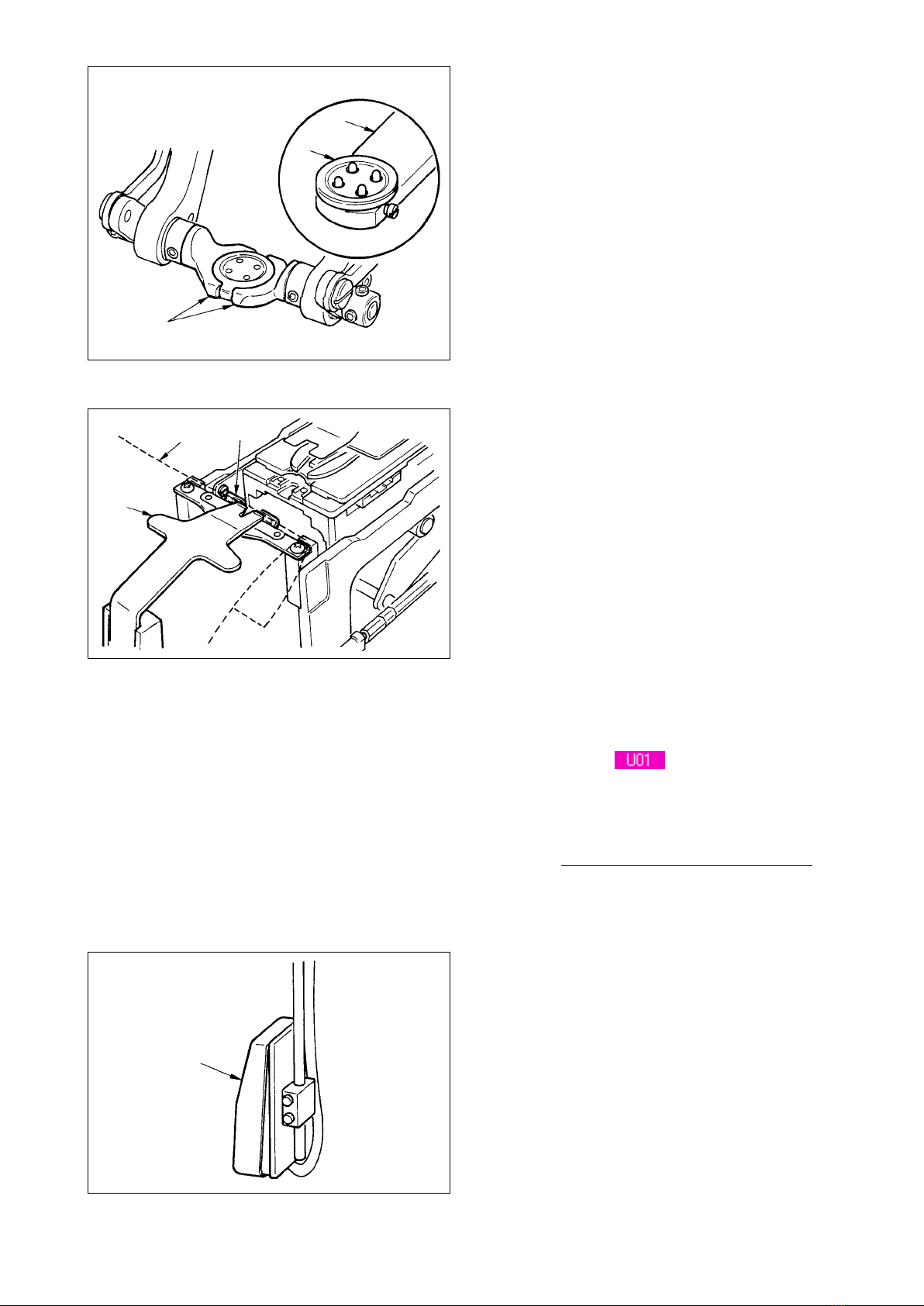

33. PERFORMING CHANGE OF NEEDLE.....................................................@- 71

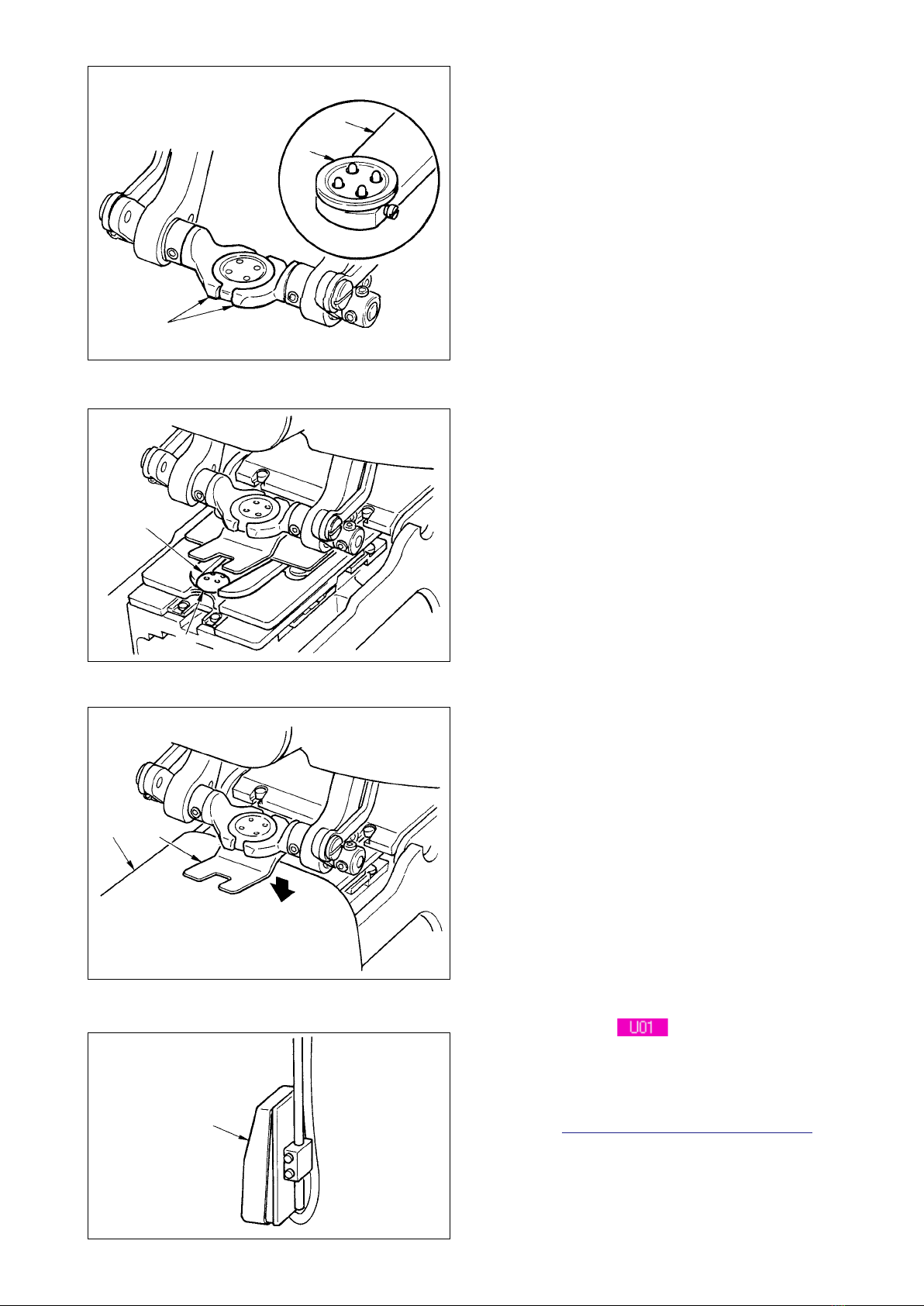

34. PERFORMING CHANGE OF CHUCK.......................................................@- 72

35. CUSTOMIZING DATA INPUT SCREEN ....................................................@- 74

(1) Registering procedure ...............................................................................................@- 74

(2) Register state at the time of your purchase.............................................................@- 75

36. CUSTOMIZING SEWING SCREEN...........................................................@- 76

(1) Registering procedure ...............................................................................................@- 76

(2) Register state at the time of your purchase.............................................................@- 77

37. PERFORMING KEY LOCK........................................................................@- 78

38. DISPLAYING VERSION INFORMATION...................................................@- 80

39. USING CHECK PROGRAM.......................................................................@- 81

(1) Displaying the check program screen......................................................................@- 81