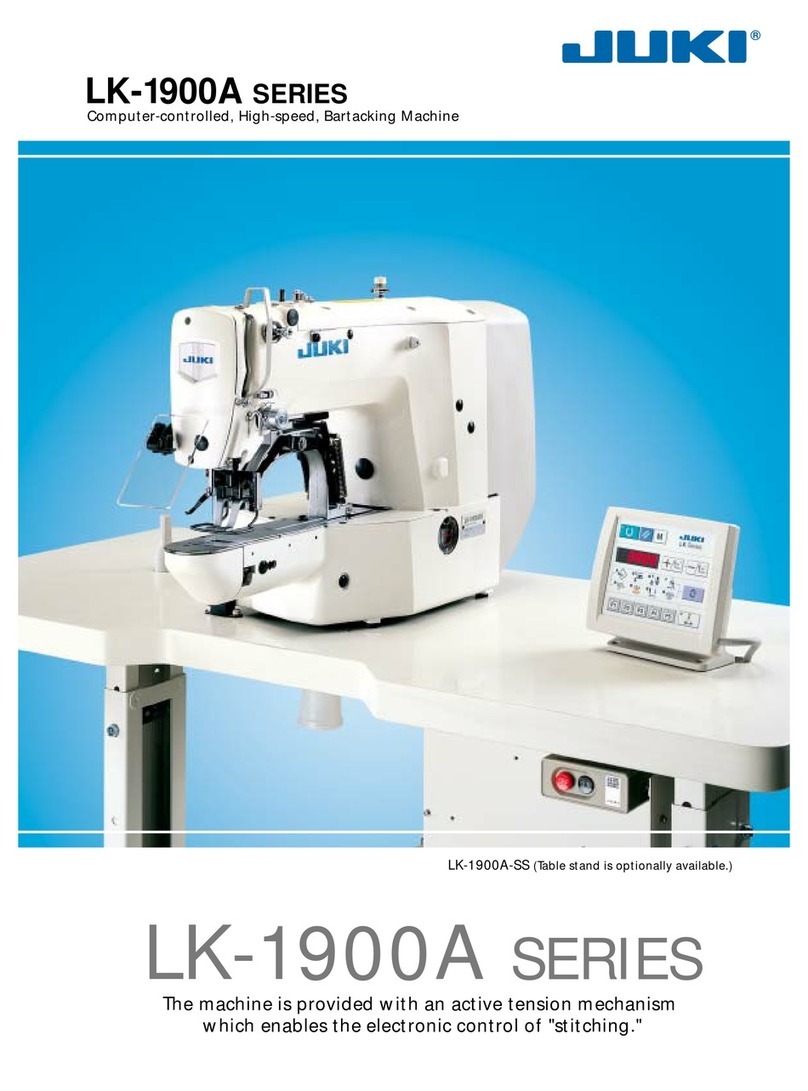

Output control function

Target No. of products display mode/Target-actual result difference

display mode

Thread trimming mechanism

Thread trimming speed has been doubled or more that of the conventional model!

Further evolved

Analysis of operator work has revealed that the working rhythm substantially affects the

productivity.Based on the aforementioned fact, JUKI focused on the thread trimming speed.

By maximizing the thread trimming speed, the operating rhythm can be improved.

The DDL-9000B trims thread at least two times faster than the conventional

thread trimmer, thanks to the improved thread-trimmer driving mechanism.

This improves the responsiveness of the sewing machine during changeovers

between sewing and thread trimming operations.

The length of time elapsing from thread trimming at the end of sewing to the start

of a subsequent operation can be shortened, thereby improving operator rhythm.

Production support function The operation panel is provided with a production support function.

Further evolved

Two different operation panels, the CP-18A and CP-180A are applicable to the DDL-9000B.

Both operation panels are provided with the production support function.

The production support function actually consists of three different functions (six different modes), which are the output control function,

operation measuring function and bobbin counter function. Each with its own production support effect. An appropriate function (mode)

can be selected as required. The parameter setting can be done on the panel located on the top of the sewing machine, thereby helping

reduce operator fatigue during setup changing.

Since operators are able to work while checking their actual number of products

on the panel at all times, they can strengthen their sense of purpose of achieving

the target, thereby increasing productivity. Operators can visually check the

progress of their work in real time, leading to the early detection of any problems

and the execution of early corrective measures.

The CP-180 is recommended for sewing difficult-to-sew

materials, hard-to-sew parts or for processes in which

lots of setup changes are required. With the CP-180A,

in addition to the functions of the CP-18A, the speed of

stitch adjustment, ON/OFF of the automatic thread

trimmer, automatic reverse stitching, double-reverse

stitching, constant-dimension sewing, rectangular

stitching and multi-layer stitching can be changed over

with a finger-tip control, thereby substantially reducing

the length of time required for setup changing.

CP-180A

Thread trimming speed has been doubled

or more that of the conventional mode

Production support function is provided

Under the target No. of products display mode, the target number of

products and the actual number of products produced according to the

work hours are displayed.

In the under target-actual result difference display mode, the difference

between the target number of products and the actual number of products

produced is displayed.

Bobbin counter function

Bobbin counter display mode

The operator is notified that the bobbin needs to be replaced before the bobbin

thread runs out.

Operation measuring function

Sewing machine availability display mode/Pitch time display mode

/Average speed of stitch display mode

Since the sewing machine operation status, pitch time (process machining time),

can be automatically measured, process analysis, line arrangement and

confirmation of facility efficiency can be obtained with ease.

As a result, the man-hours required for production control are reduced.

Under the sewing machine availability display mode, the average sewing

machine availability in the previous cycle and the current cycle is displayed.

Under the pitch time display mode, the average process machining time in

the previous cycle and the current cycle is displayed.

Under the average speed of stitch display mode, the accumulated speed

of stitch in the previous cycle and the current cycle is displayed.

The CP-180A is recommended if you use

the DDL-9000B for a difficult sewing process.

CP-18A