CONTENTS

pa??=

.............................

1.

HOWTOSETUFTHEMACHINE

1

1)

How to install the oil reservoir

.............................

1

...............................

2)

Motor pulley and the belt

1

2.

HOW TO OPERATE THE MACHINE

...........................

2

-

...................................

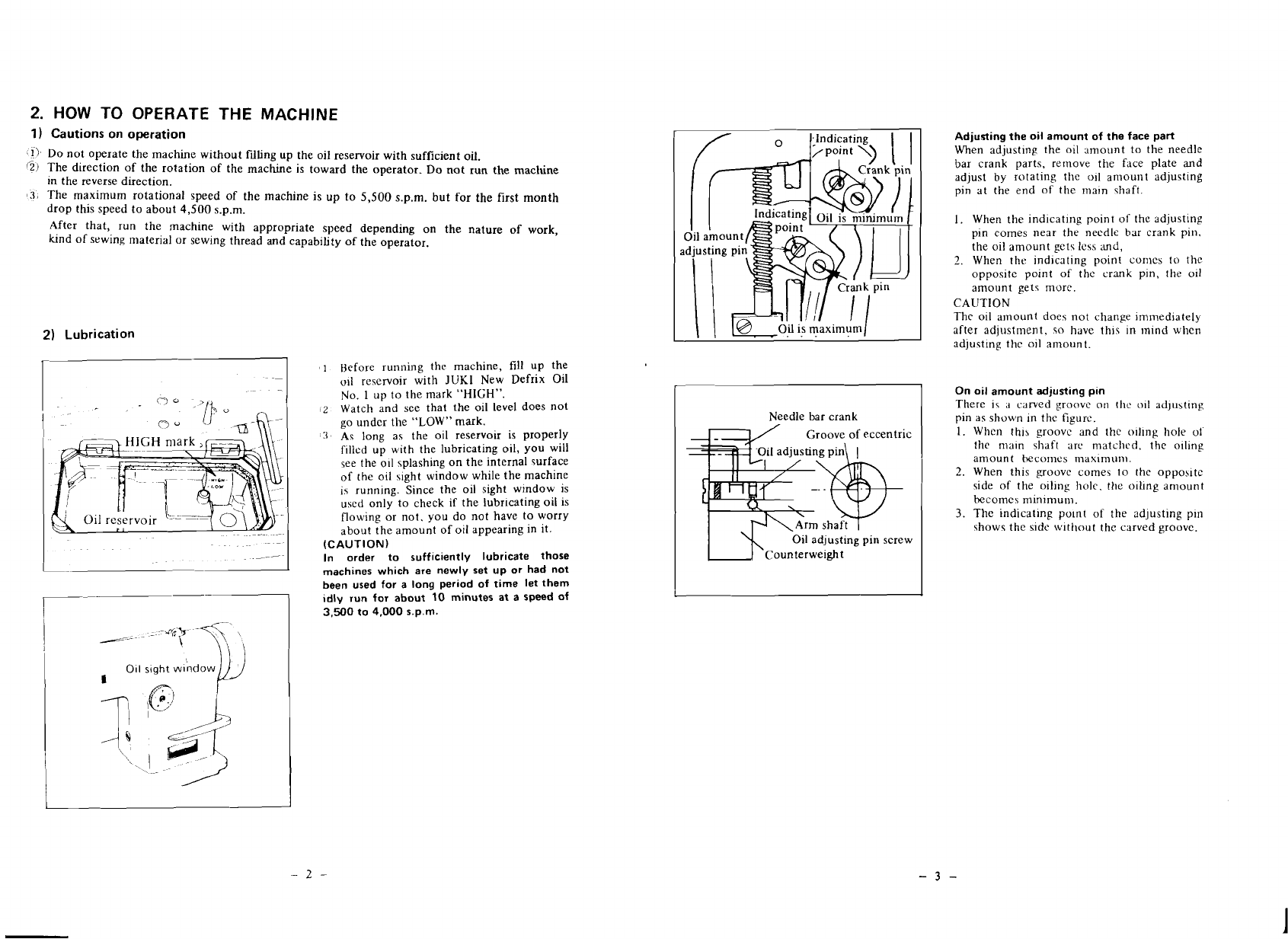

1) Cautions on operation 2

2)

Lubrication

.........................................

2

Adjusting the oil amount of the face part

.....................

3

On oil amount adjusting pin

...............................

3

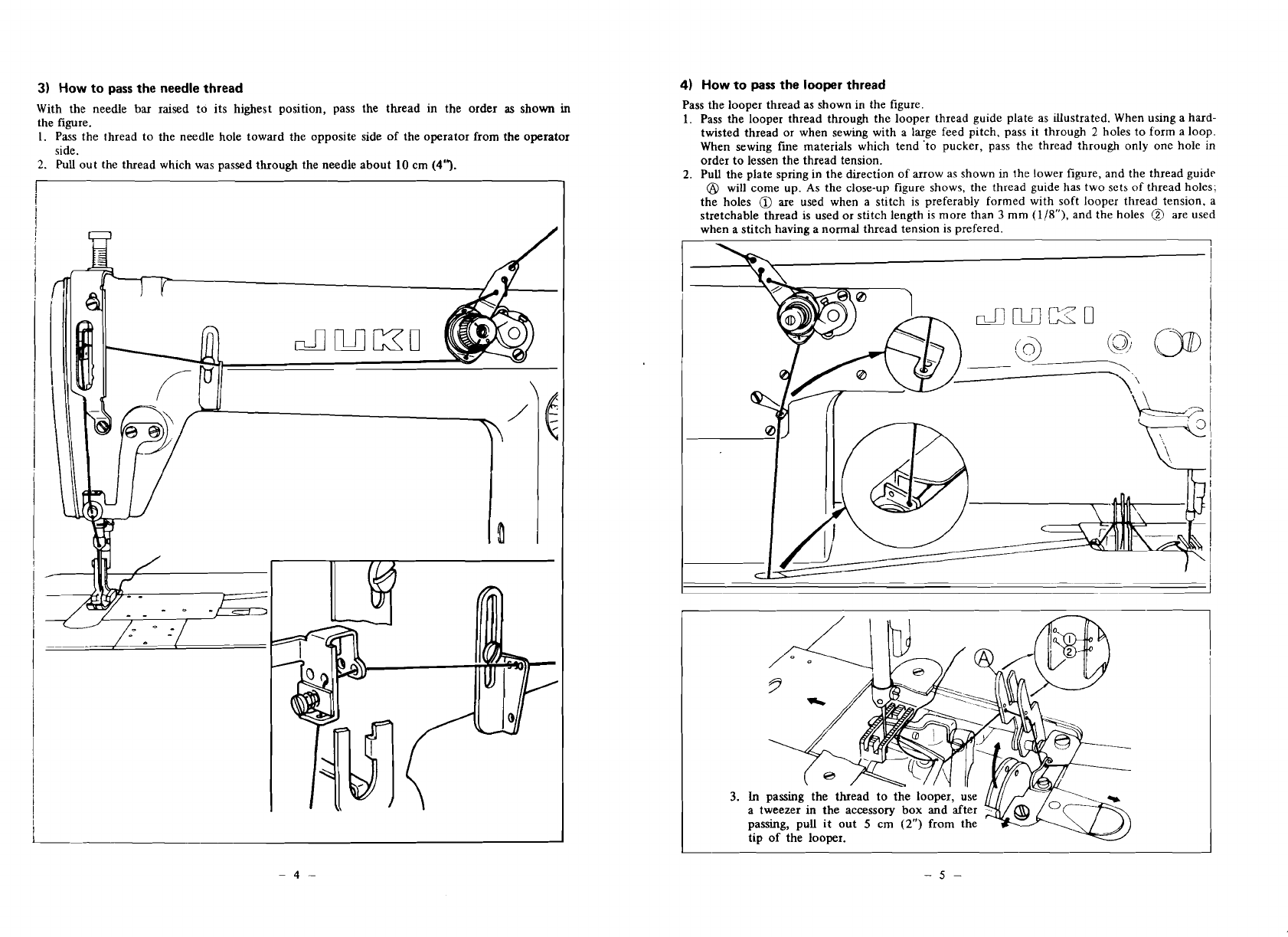

3) How to pass the needle thread

.............................

4

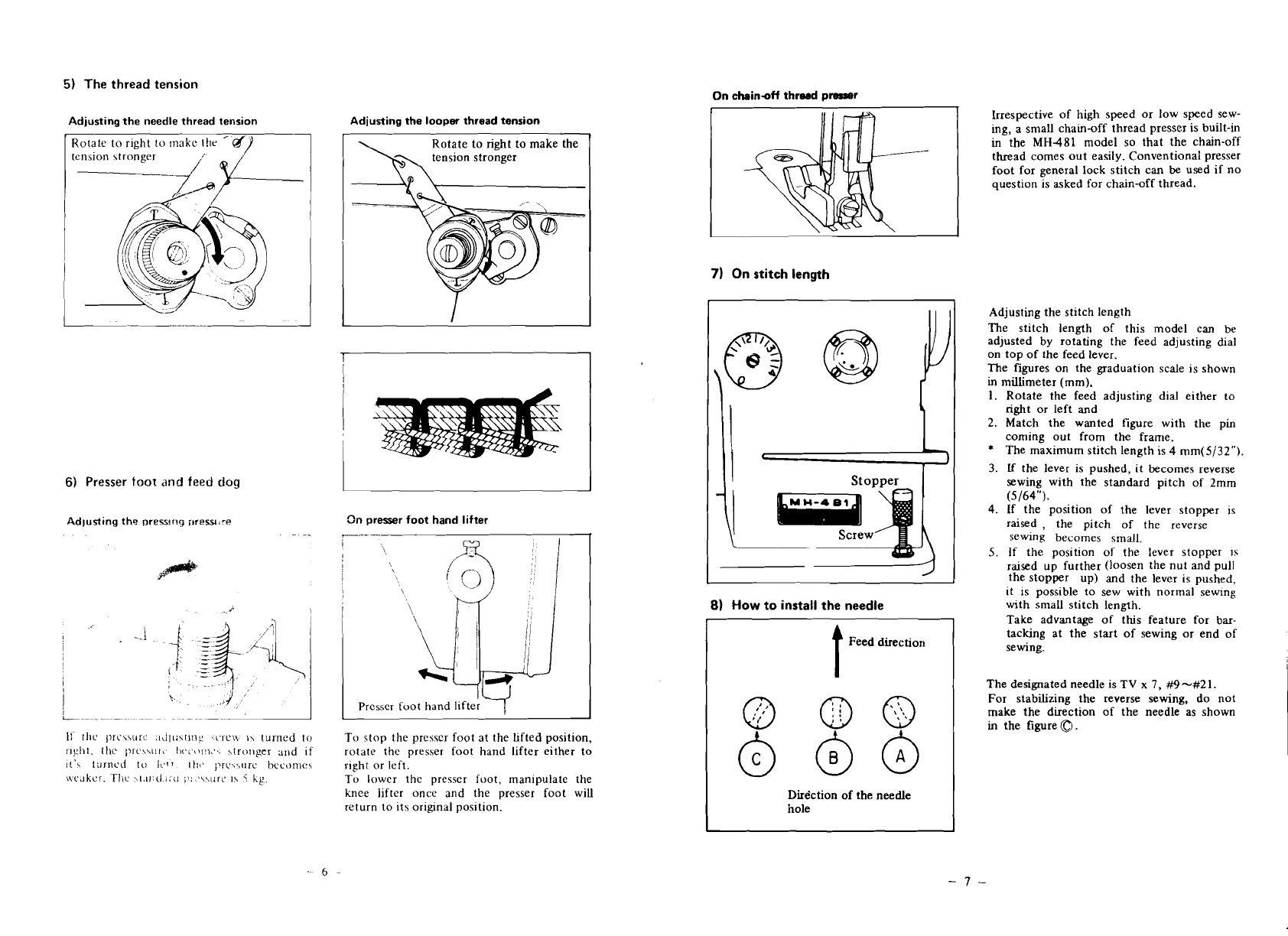

4) How to pass the looper thread

.............................

5

....................................

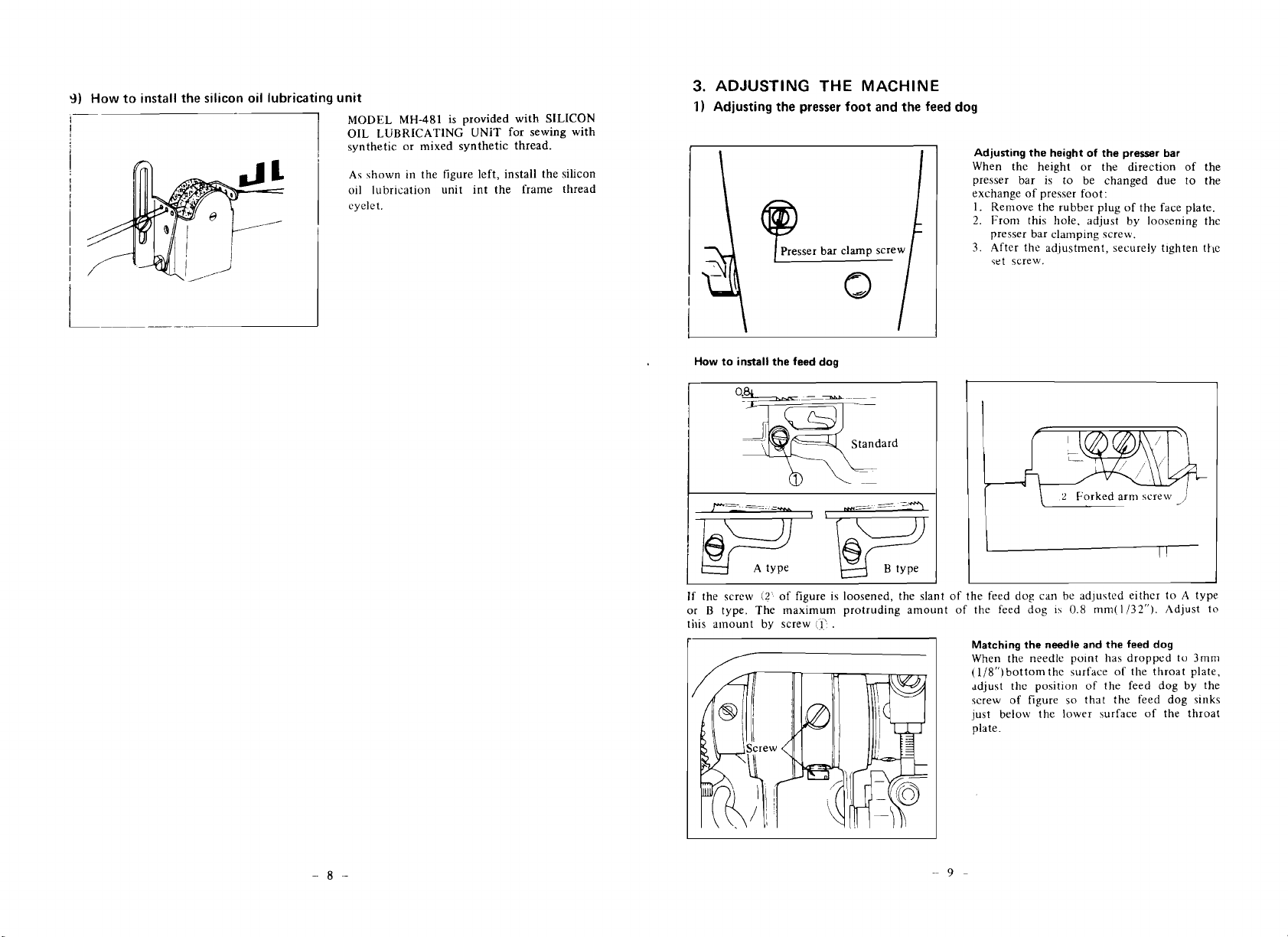

5) The thread tension.

6

.........................

Adjusting the needle thread tension

6

.........................

Adjusting the looper thread tension

6

...............................

6) Presser foot and feed dog

6

Adjusting the pressing pressure

.............................

6

................................

On presser foot hand lifter

6

On chain-off thread presser

...............................

7

7)

On stitch length

.....................................

7

...............................

Adjusting the stitch length

I

8)

How to install the needle.

................................

7

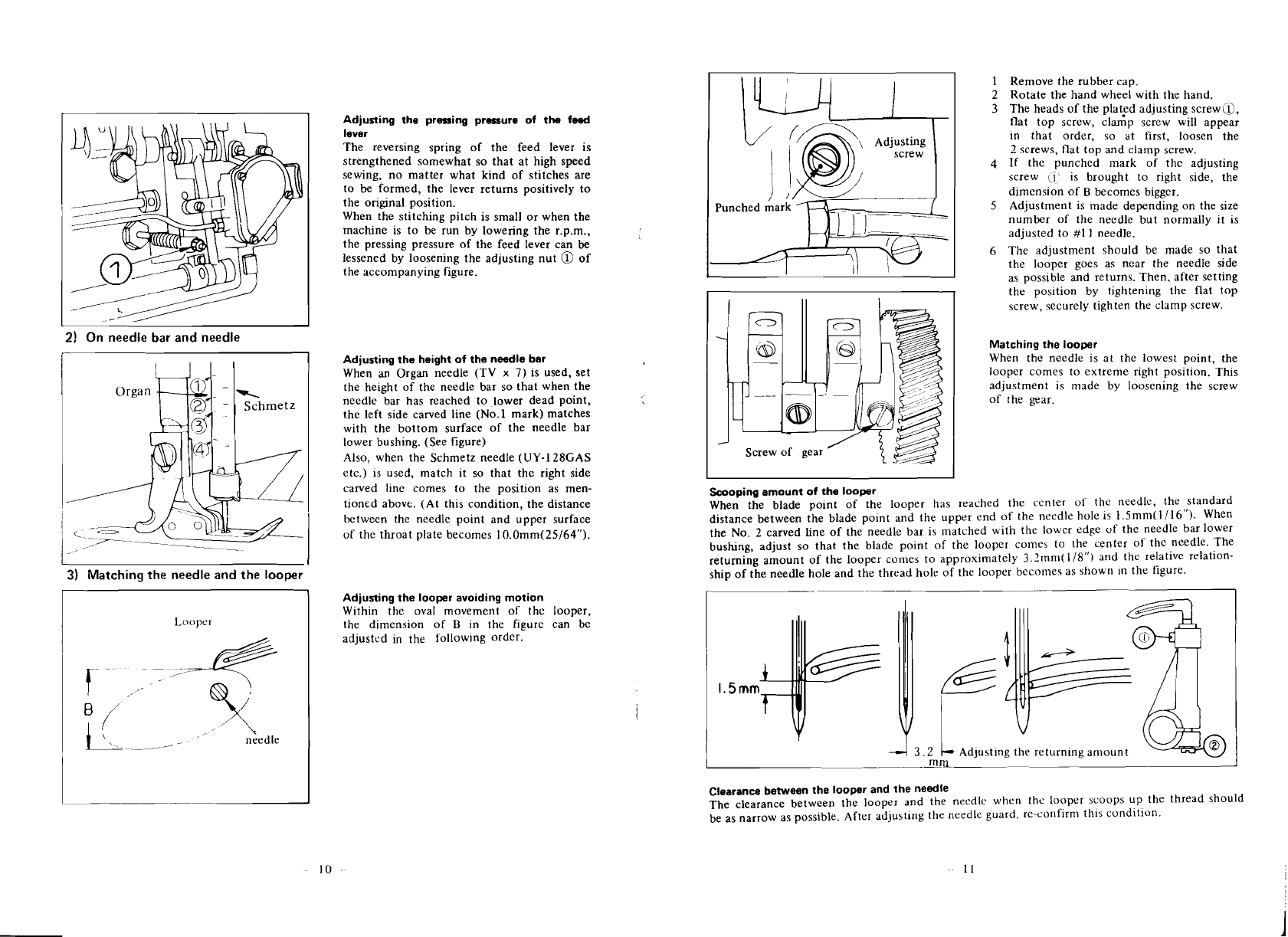

9)

How to install the silicon oil lubricant unit

.....................

8

3. ADJUSTING THE MACHINE

...............................

9

.....................

1) Adjusting the presser foot and the feed dog 9

Adjusting the height of the presser bar

.......................

9

How to install the feed dog (MH-481)

........................

9

Matching the needle and the feed dog

.........................

9

..................

Adjusting the pressing pressure of the feed lever. 10

................................

2)

On needle bar and needle. 10

Adjusting the height of the needle bar.

........................

10

-

-

3) Matching the needle and the looper

.........................

10

Adjusting the looper avoiding motion

.........................

10

Matching the looper

...................................

11

Scoopingamount of the looper

..............................

Clearance between the looper and the needle. 11

....................

11

4)

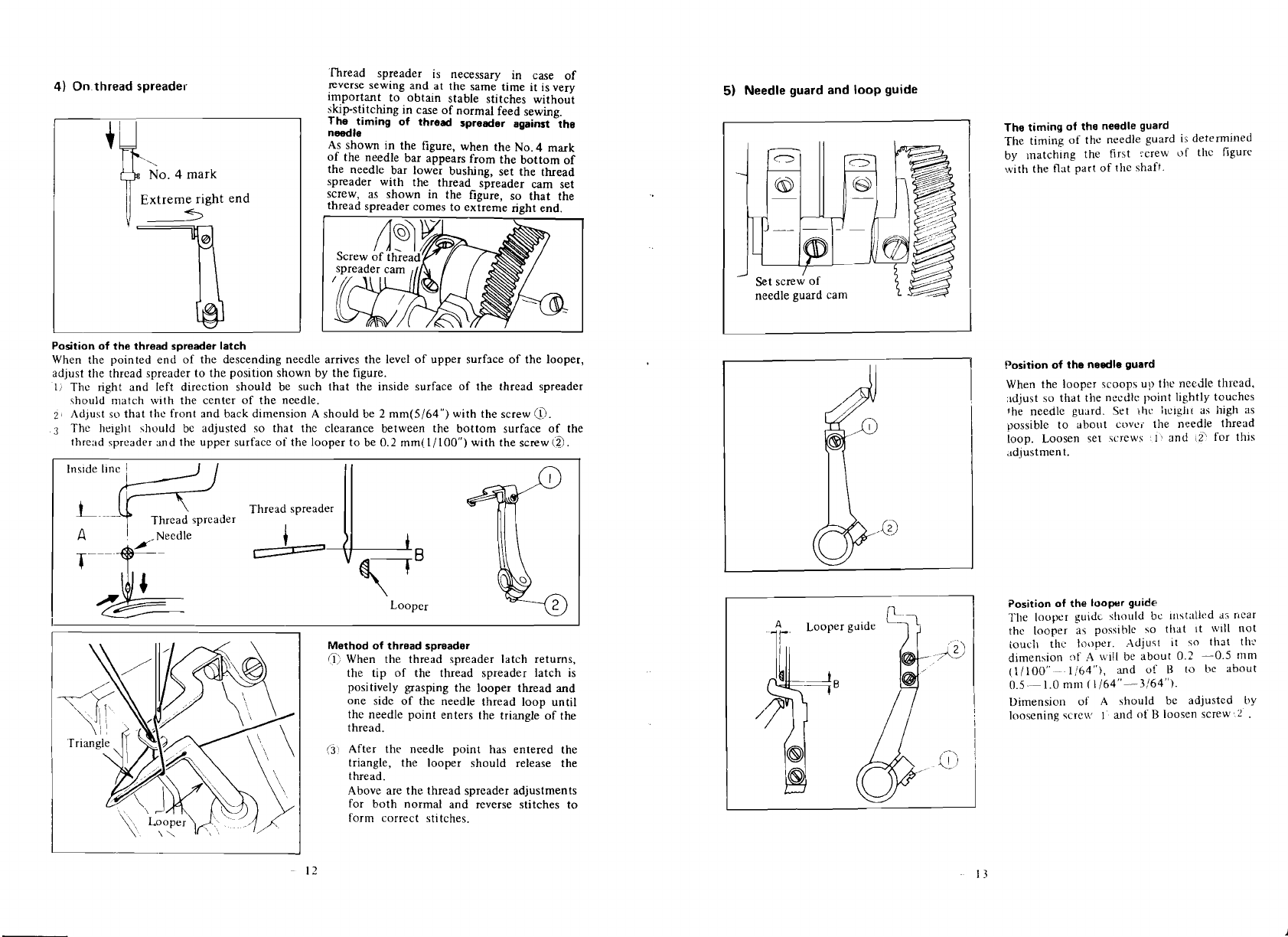

Onthreadspreader

.....................................

12

The timing of thread spreader against the needle

.................

12

Position of the thread spreader latch

.........................

12

Method of threhd spreader

...............................

12

5)

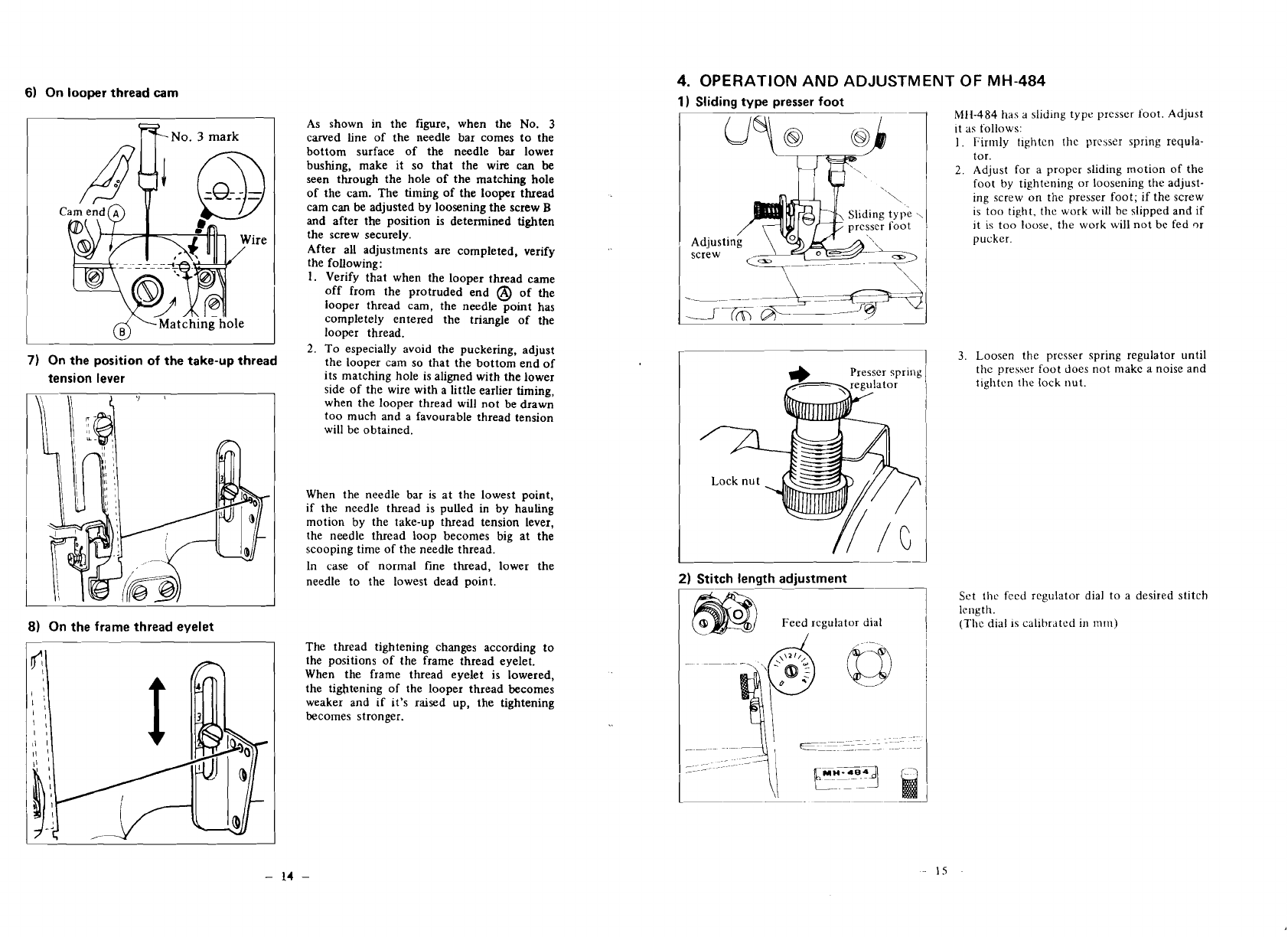

Needle guard and loop guide.

..............................

The timing of the needle guard 13

.............................

12

A"

...............................

Position of the needle guard 13

...............................

Position of the looper guide 13

...................................

6)

On looper thread cam I4

7)

On the position of the take-up thread tension lever.

................

14

8)

011

the frame thread eyelet

...............................

14

4.

OPERATION AND ADJUSTMENT OFMH-484

.....................

15

5. b1AINTI:NANCE OFTIIE MACHINE

...........................

19

6.

MALI'UNCTIONS

AN[)

CORRECTIVE MEASURES

..................

19

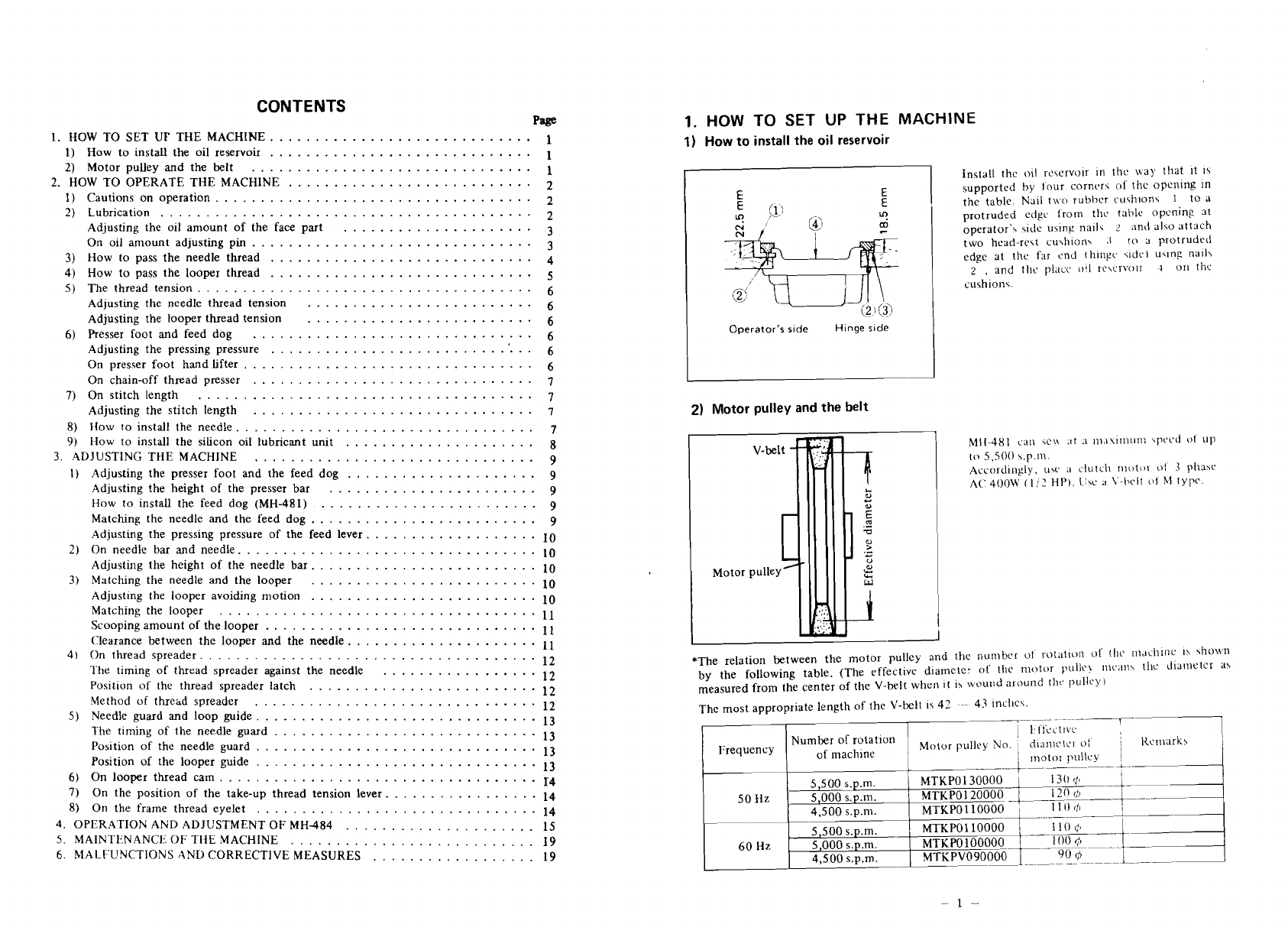

1.

HOW

TO

SET

UP

THE

MACHINE

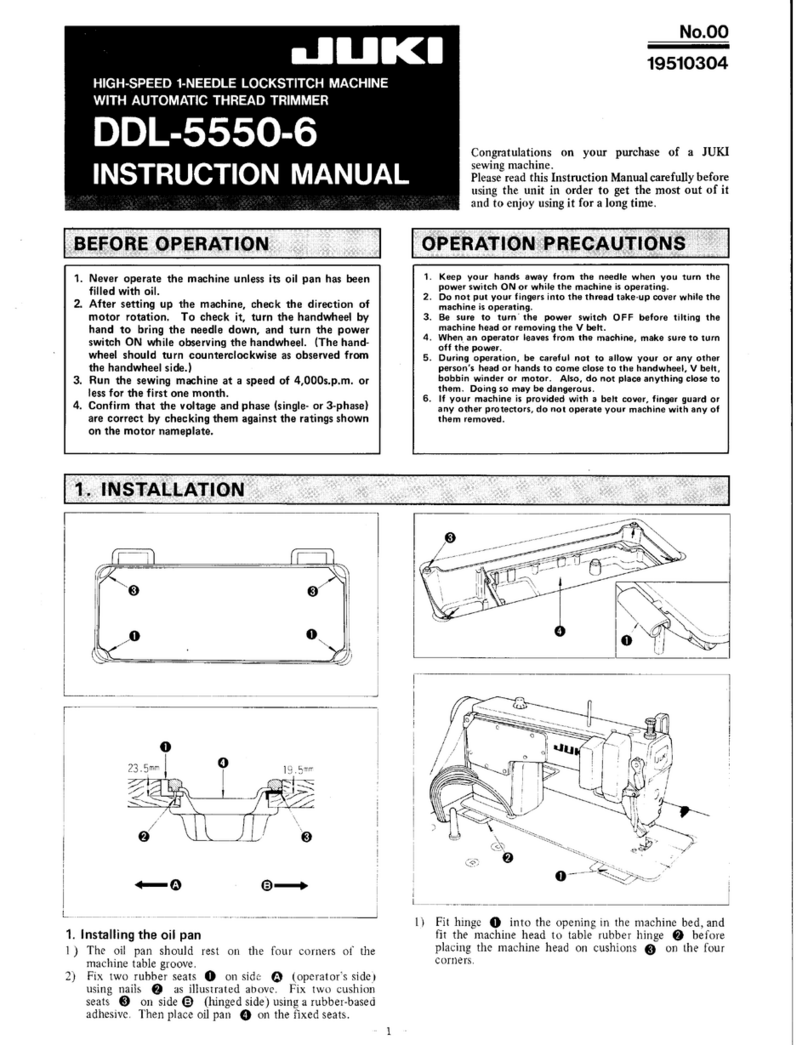

1)

How to install the oil reservoir

Operator's s~de

Hinge

side

Install the oil rcwrvolr In

thc

\lay that ~t

I5

supported by lour cornrrs

of

the opening In

the table. Nail t\\.o rut~hrrrurhion\

1

to

a

protruded edgc from thc tahle opening at

operator'\ cidc using nail?

2

and alw attach

two head-rest cu\h~on\

.(

to

3

protrudeii

edge at thc far cnd Ihingc crdc) Uclng nail5

2

,

and thc placv

i11l

rc\crvolr

.1

on thc

cuthion.;.

Il

2)

Motor pulley

and

the belt

Mil-481

can

\c\\

at

a

~ii,i\i~iiiin~'PCCJ

111

llp

to

5,500

\.p.n\.

Accordingly, uw

;I

clutch rliotor

ol

3

phahc

A('

400W

(1

'7

ill').

\<c

:I

\'-l)t-lt

01

X1

typc.

*The relation between the lllotor pulley and the number

ui

!-ot;~tlun

of

111~'

r~ldchlnc

IS

\h~\\'ll

by the following table. (The effective diameter

of

the motor pullc\ I1lr;rI1\ tllc Jiarnetcr aS

measured from the center of the V-belt when ~tis wourld around th?,pullc).)

The most appropriate length of the V-belt

IS

41

--

43

incllc\.

..

-p~

j

1~t'sci.rlv~

1

'

d~anlctci

oi

Kcrl~arkh

.

I

not0

I

'i