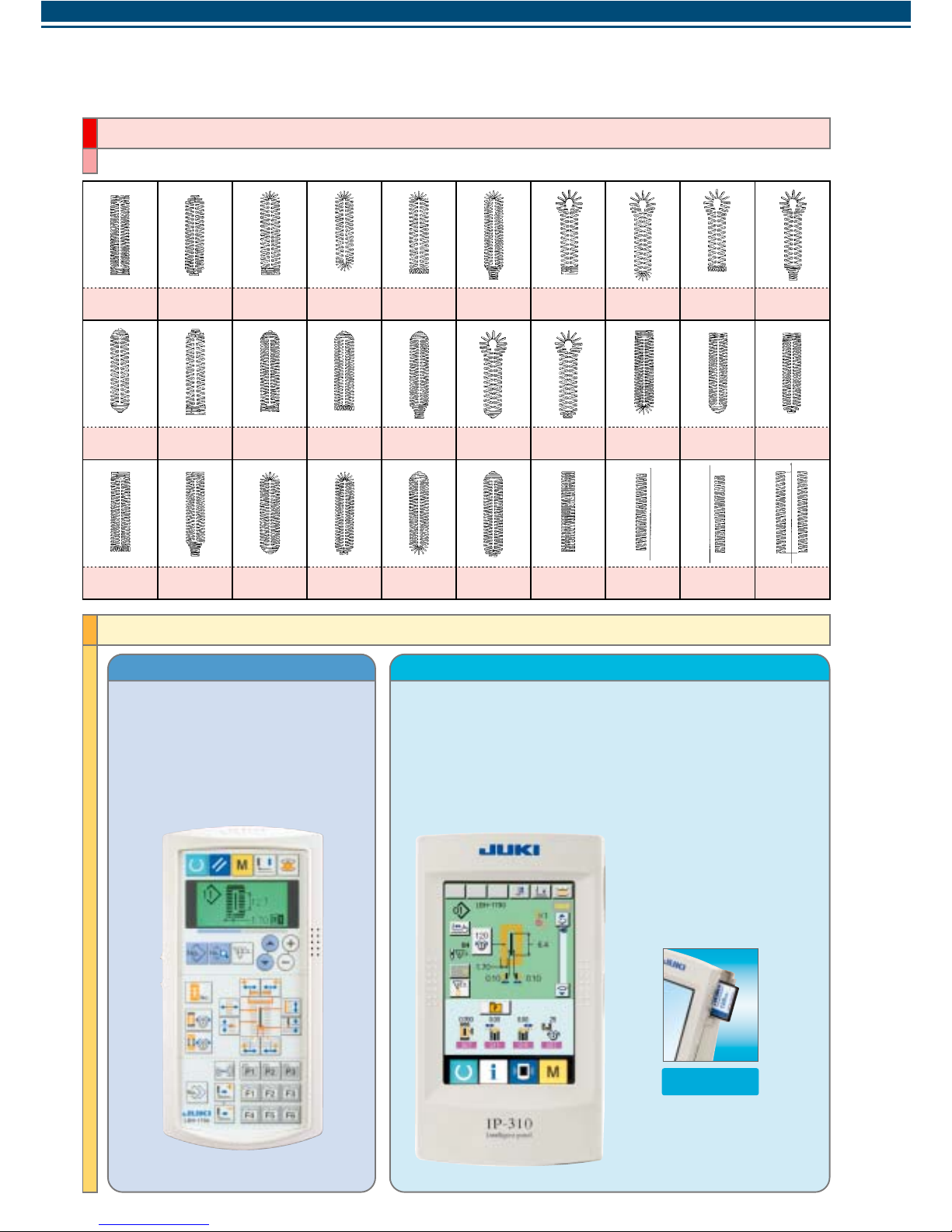

Buttonholes are

positioned at right angles

to the top-center plaits.

A

C

B

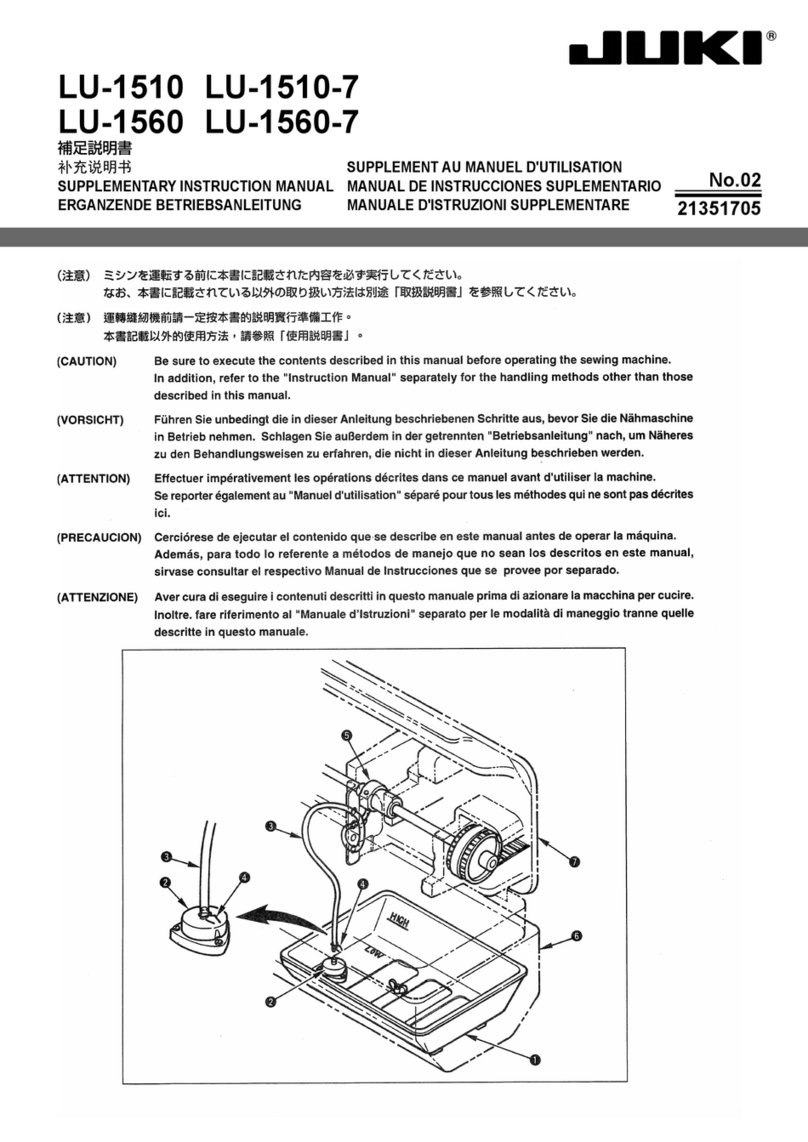

LBH-783NB

Q060

SK-1 AO17

Q061 Q066

LBH-782NB

At the very least, a good buttonholing machine should

finish seams of consistent quality and be widely

adaptable to many different kinds of materials and seam

specifications. The LBH-780 series buttonholing machines

respond to these needs and help reduce operator fatigue,

thereby finishing high-quality buttonholes with a higher

degree of efficiency.

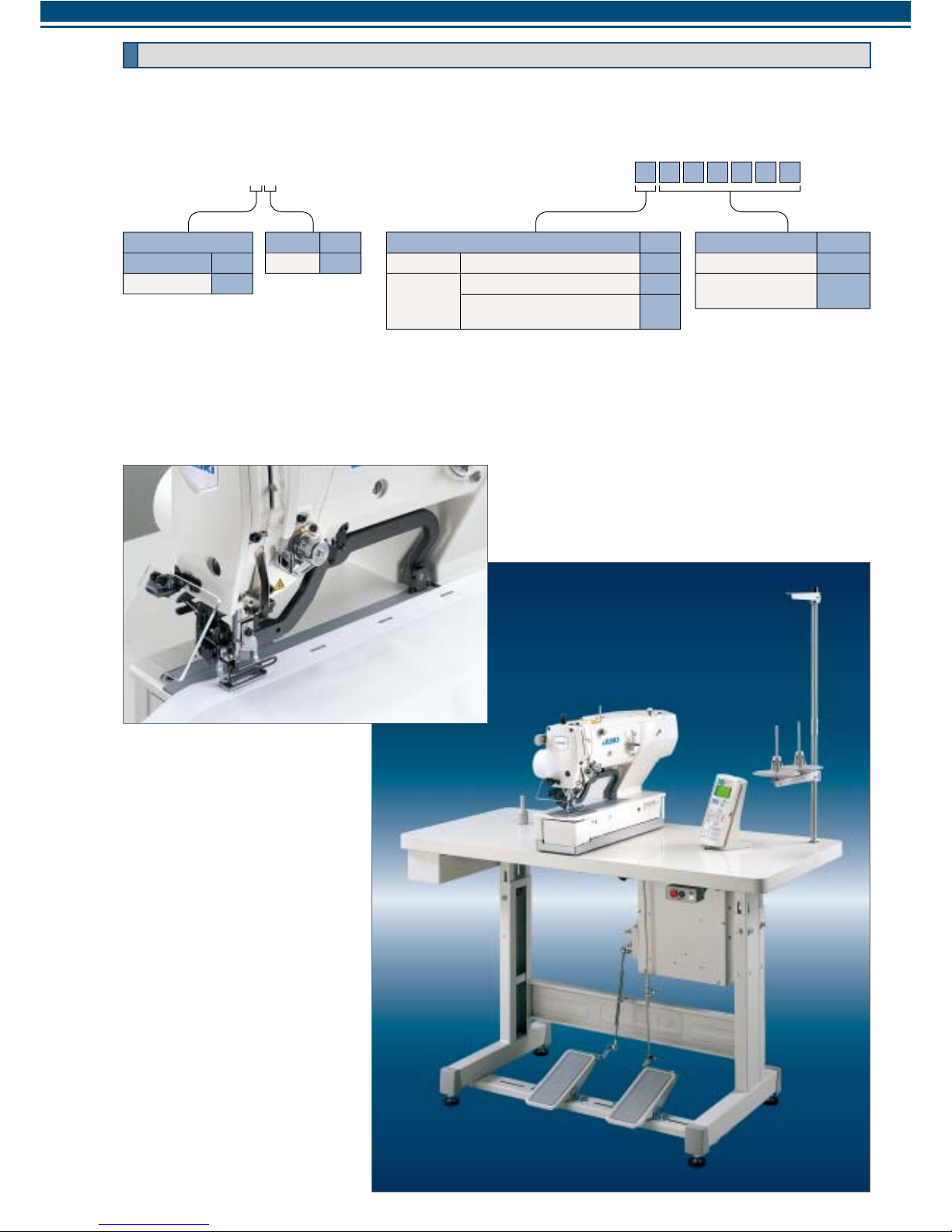

The buttonholing position can be easily adjusted. This further

enhances ease of operation.

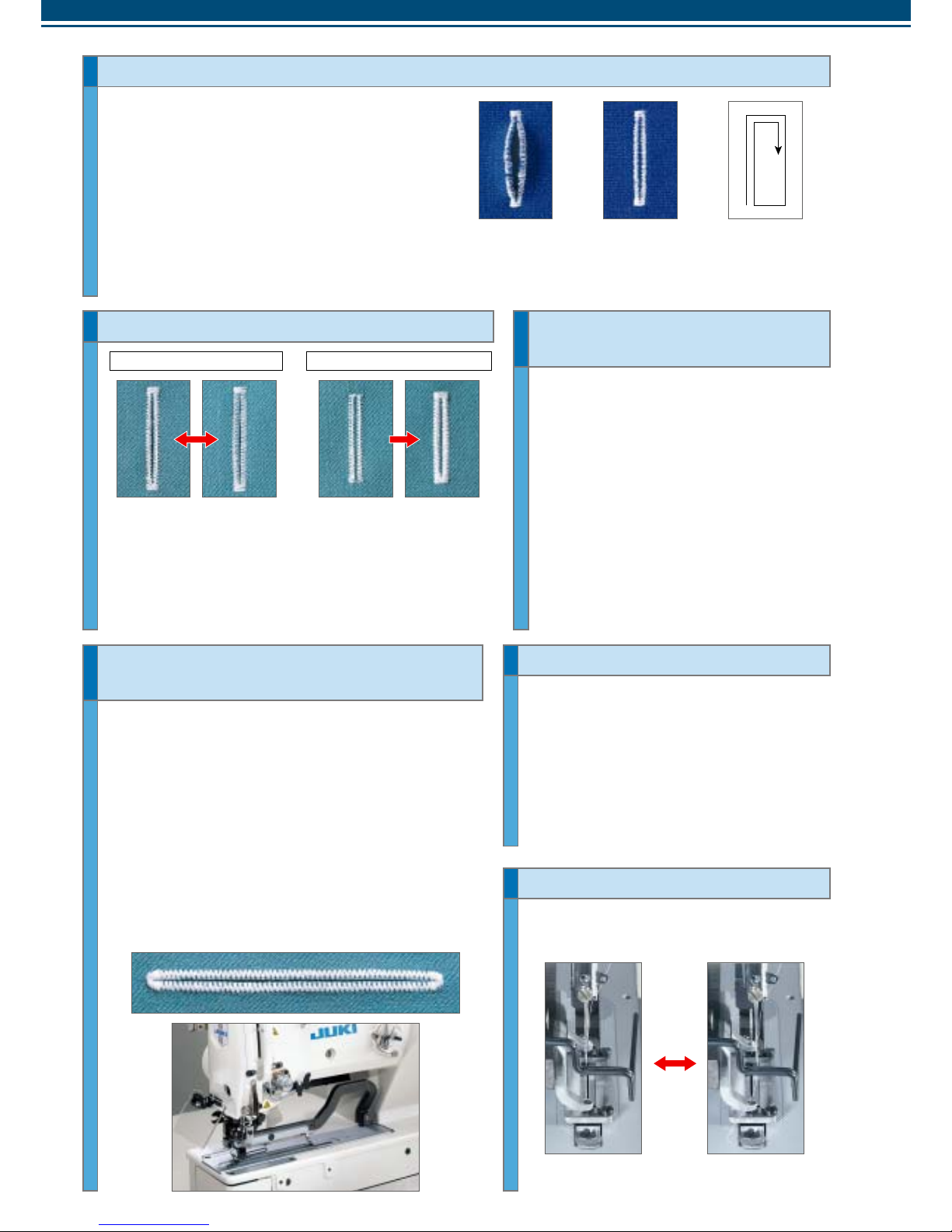

A newly introduced mechanism in the needle thread trimmer

prevents interference with the positioning of buttonholes. The shape

of the face plate is designed to provide sufficient clearance around

the needle entry position. As a result, ease of operation is further

improved.

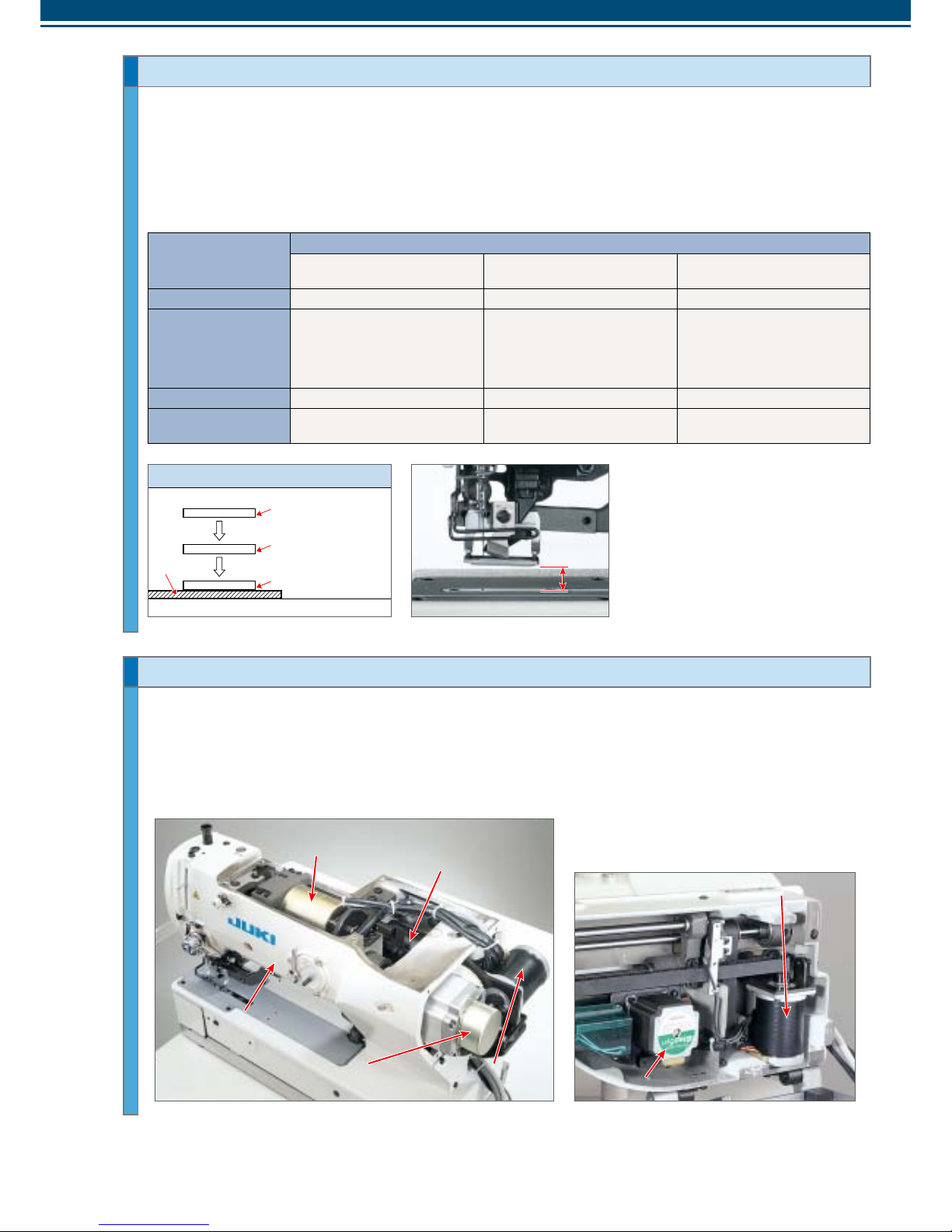

The work clamp can be lifted as high as 12mm. The machine is

capable of sewing heavy-weight materials such as bulky knits.

The maximum lift of the work clamp is 12mm, enabling the machine

to make high-quality buttonholes in heavy-weight materials.

Work clamp can be easily lifted. This helps to substantially reduce

operator fatigue. The pressure required to depress the start pedal

and lifter pedal has been reduced. This helps to dramatically reduce

operator fatigue.

The knife mechanism and stop-motion mechanism produce less noise

when they actuate, thus contributing to a more comfortable working

environment. Thanks to the simple design of the stop-motion

mechanism and unique knife mechanism, the machine operates with

low noise. The machine starts, decelerates and stops smoothly.

A new LBH series model has been designed for a round-type

of bartacking for ladies' wear with a soft, femine touch. With

this new model, finished products provide a soft feeling.

●This needle entry point can visually

checked. This permits easy

positioning of buttonholes.

●The lift of the work clamp is as

high as 12mm.

Square-type bartacking Round-type bartacking

■

LIST OF THE SUBCLASS MACHINES ACCORDING TO THEIR APPLICALIST OF THE SUBCLASS MACHINES ACCORDING TO THEIR APPLICATIONSTIONS

■

LIST OF THE SUBCLASS MACHINES ACCORDING TO THEIR APPLICALIST OF THE SUBCLASS MACHINES ACCORDING TO THEIR APPLICATIONSTIONS

■

LIST OF THE SUBCLASS MACHINES ACCORDING TO THEIR APPLICATIONS

■

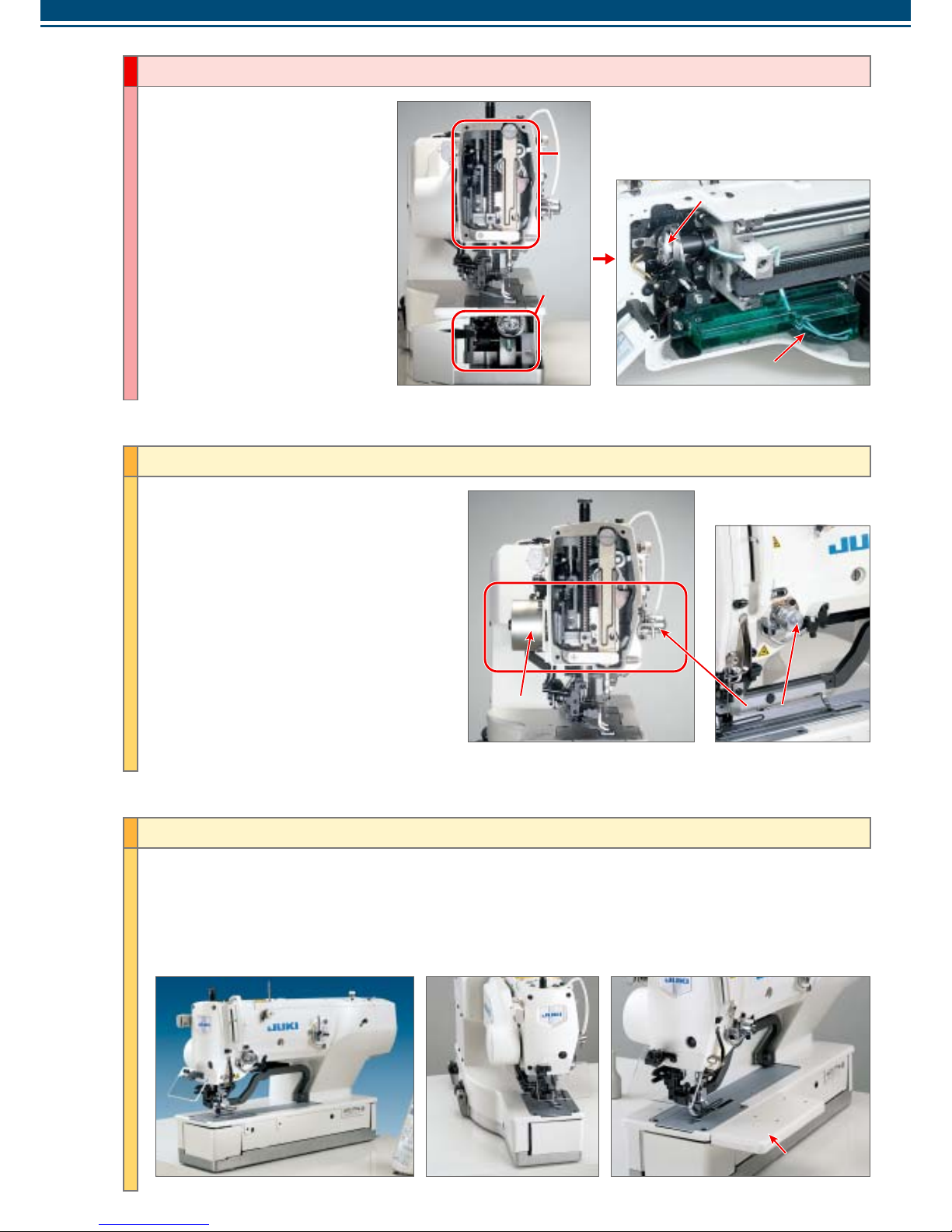

OPTIONS

■

OPTIONS

■

OPTIONS

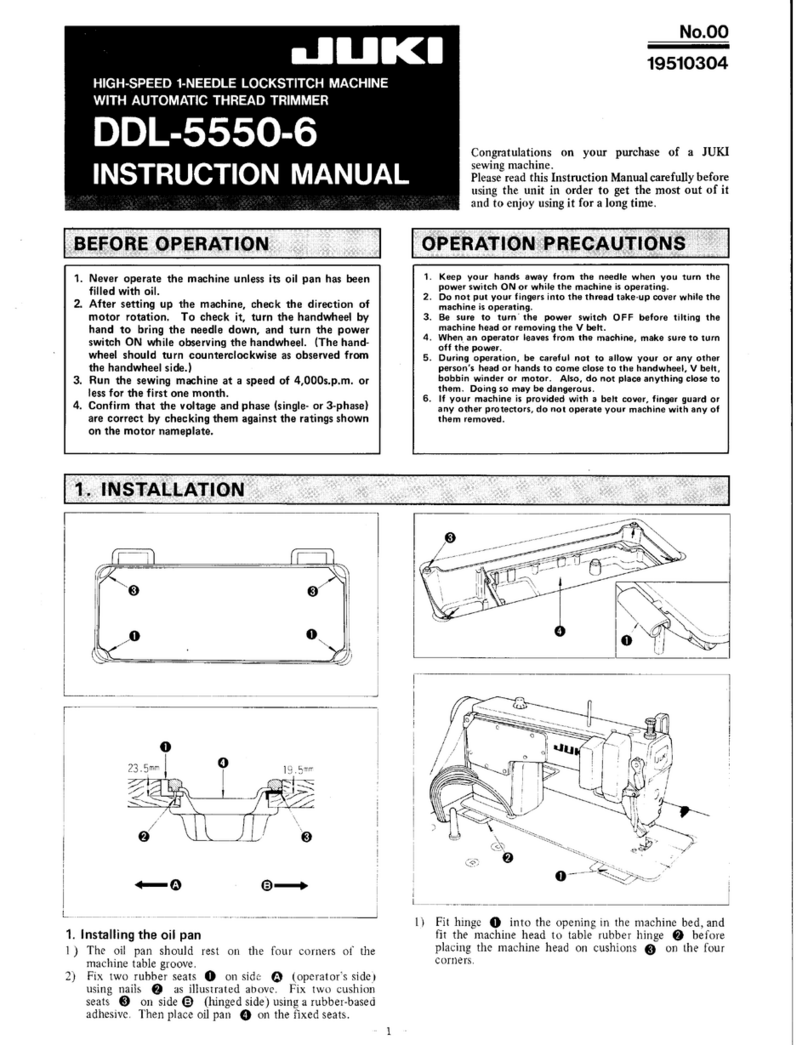

Model

Q060

Q061

Q066

SK-1

AO17

Part No.

MAQ-060000A0

MAQ-061000A0

MAQ-066000A0

―

―

Description

Men's shirts

Ladies' blouses

Spacer for buttonholes on top-

center plaits

Pneumatic knife driving unit

Automatic single-pedal unit

Feature

Spacer for first bottonholes

This is a ruler to be used to set the first buttonhole at a predetermined position

in accordance with the shape of the collar.

Adjustable regardless of the dimensions and shape of collars.

This is a ruler to be used for sewing lateral buttonholes in the process of

buttonholing top-center plaits.

The ruler is provided with four positioning pointers on the right and left.

Each of the pointers can be shifted with a single motion.

The SK-1 pneumatic knife driving unit cuts the material by tapping a flat knife

and nylon plate on the material. This prevents the tensing-up of texture yarns

that so often occurs when sewing glossy synthetic materials.

―

Buttonholing size (in mm)

*1…Dimension A : 9.5 〜25.4mm *2…Dimension A : 9.5 〜31.8mm *3…Dimension A : 11.5 〜25.4mm *4…Dimension A : 11.5 〜31.8mm

Stitch formation

LBH-781U

LBH-781KU

―

―

LBH-782U

LBH-782KU

*1

LBH-782NV

LBH-782NV1

*3

LBH-782NB

LBH-782NB1

LBH-783U

LBH-783KU

*2

LBH-783NV

LBH-783NV1

*4

LBH-783NB

LBH-783NB1

6.4 〜31.8

2.5 〜5.0

Max. 40

A

B

C

6.4 〜25.4

2.5 〜5.0

Max. 33

A

B

C

6.4 〜19.1

2.5 〜4.0

Max. 22

A

B

C

Standard

type

Ktype:

For Knits

NV type :

Double-

stitching

with gimp

NB type :

Double-

stitching with

gimp and

gimp cutter

Men's shirts, blouses, working wear,

ladies' wear

Knitting fablic underwear, knit products

including sweaters, cardigans and

tights, medium-weight material

including working wear.

Sweater, polo shirts, knits, and jersey

wear made of the materials which need

to be sewn with especially durable

stitches.

Same with the application of the NV

type models. NB type model is

equipped with the automatic gimp

cutter.

Subclass

models Application

The machine neatly tucks in tetron gimps with consistency.

Thanks to the improved locus of the gimp guide, the machine is

flexibly adaptable to changes in the types of gimps to be used, easily

switching operation to accommodate one to three pieces of tetron

thread, or one sewing thread and one span thread. In addition, the

gimp guide is designed so that it shifts vertically. This means that

the relation between the needle and the gimp guide is uniform even

if the material thickness varies, thus allowing the machine to tuck in

gimps with consistency.

A machine is designed for sewing soft-to-the-touch circular bartacks.

It has been developed to sew circular bartacks on ladies' wear, a

process that requires a very delicate finish.

The machine ensures stable stitching performance on multi-layered

portion of the material. The improved work clamp and its

fulcrumsecurely hold multi-layered portions of a heavy-weight

material, thereby preventing sewing troubles such as uneven material

feed, slip-off of gimp and needle breakage. This allows the machine to

perform buttonholing with consistency.

The gimp cutter dramatically promotes lobor-saving. (NB type)

The length of remaining gimp after its trimming is only about 2mm.

This eliminates the thread cropping procedure in the after-process,

thereby increasing productivity. The distance between the gimp-

cutting scissors and the needle scarcely changes when sewing multi-

layered portions of the material, thus ensuring consistent gimp-

cutting at any occasion.

LBH-780 SERIES

LBH-780 SERIES

LBH-780NV

LBH-780NV

LBH-780NB

LBH-780NB

(for double-stitching with gimp)

(for double-stitching with gimp and gimp cutter)

12mm