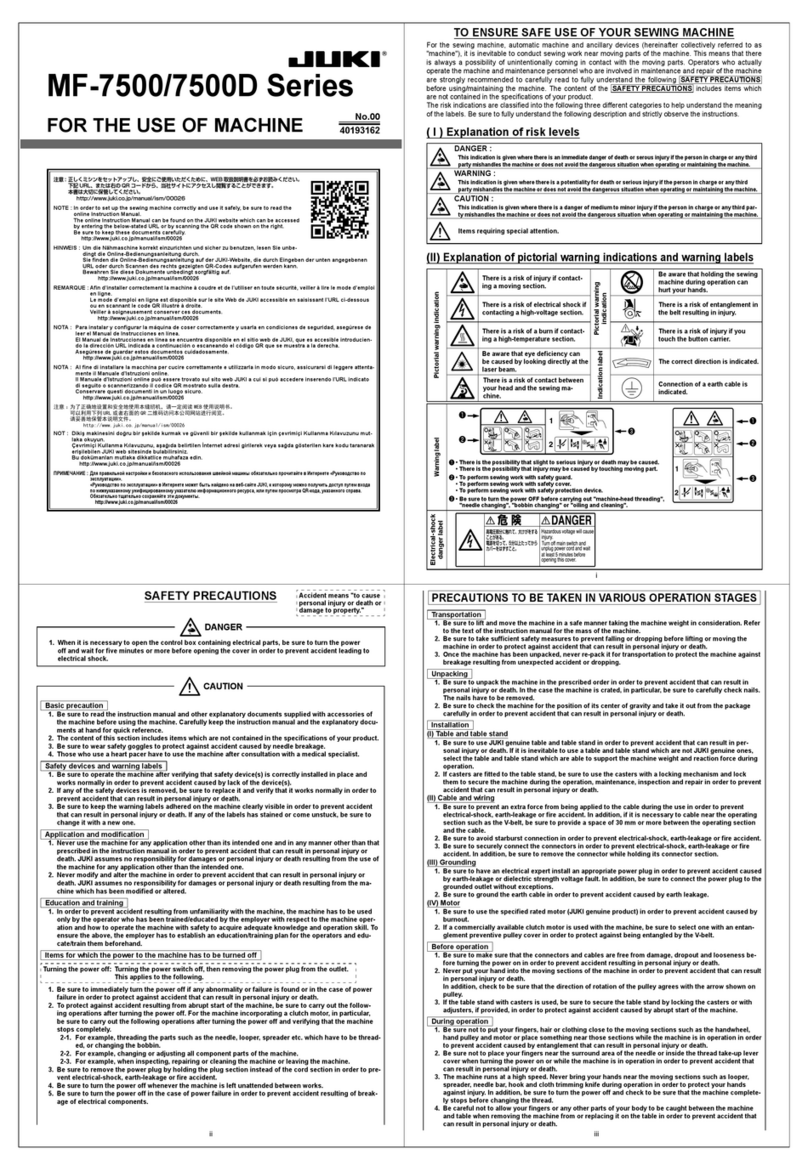

CONTENTS

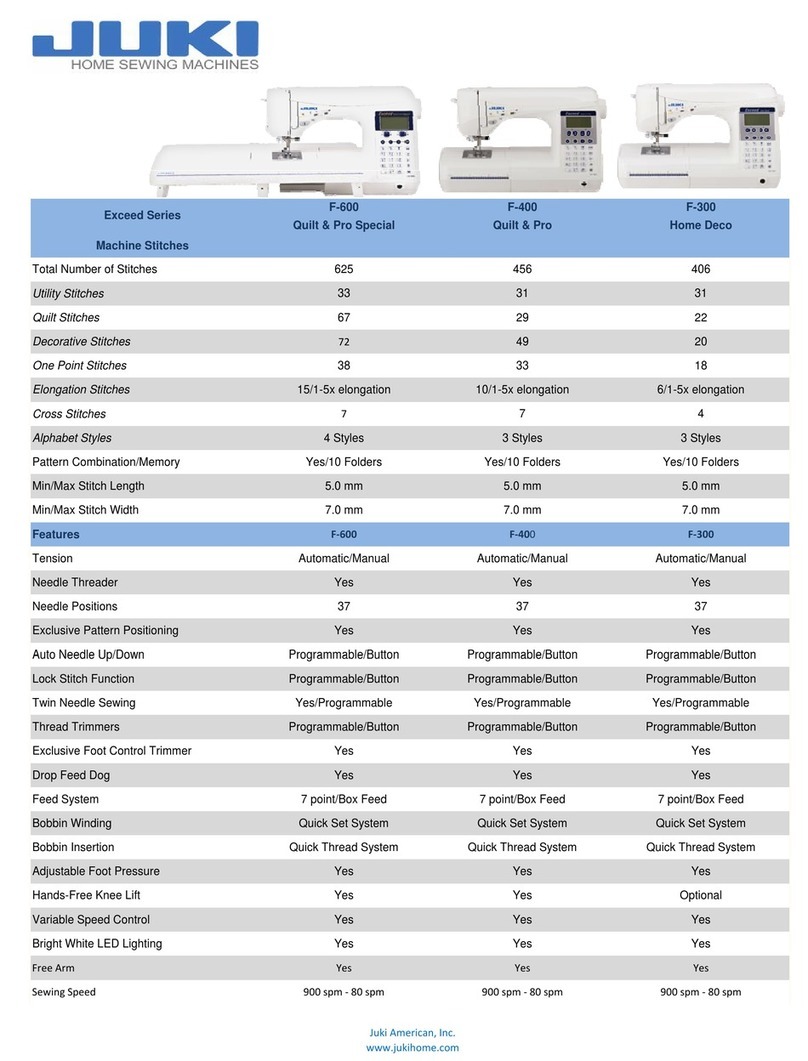

1SPECIFICATIONS............................................................................ 1

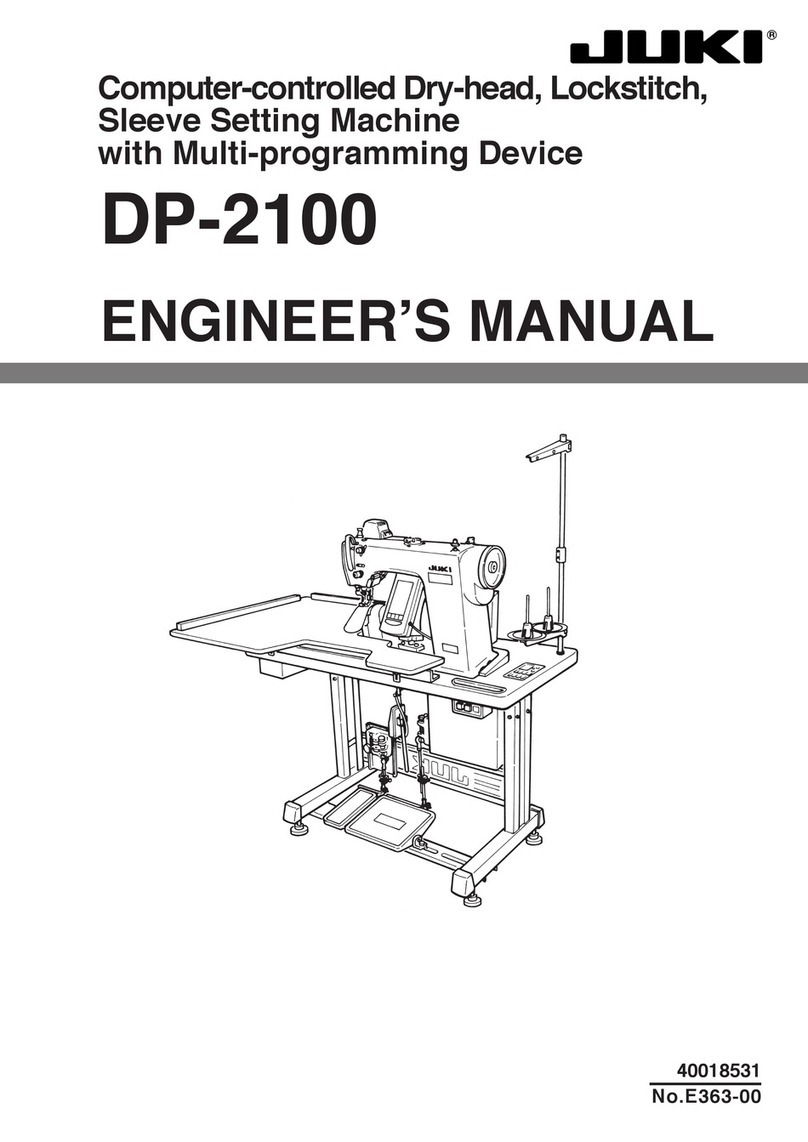

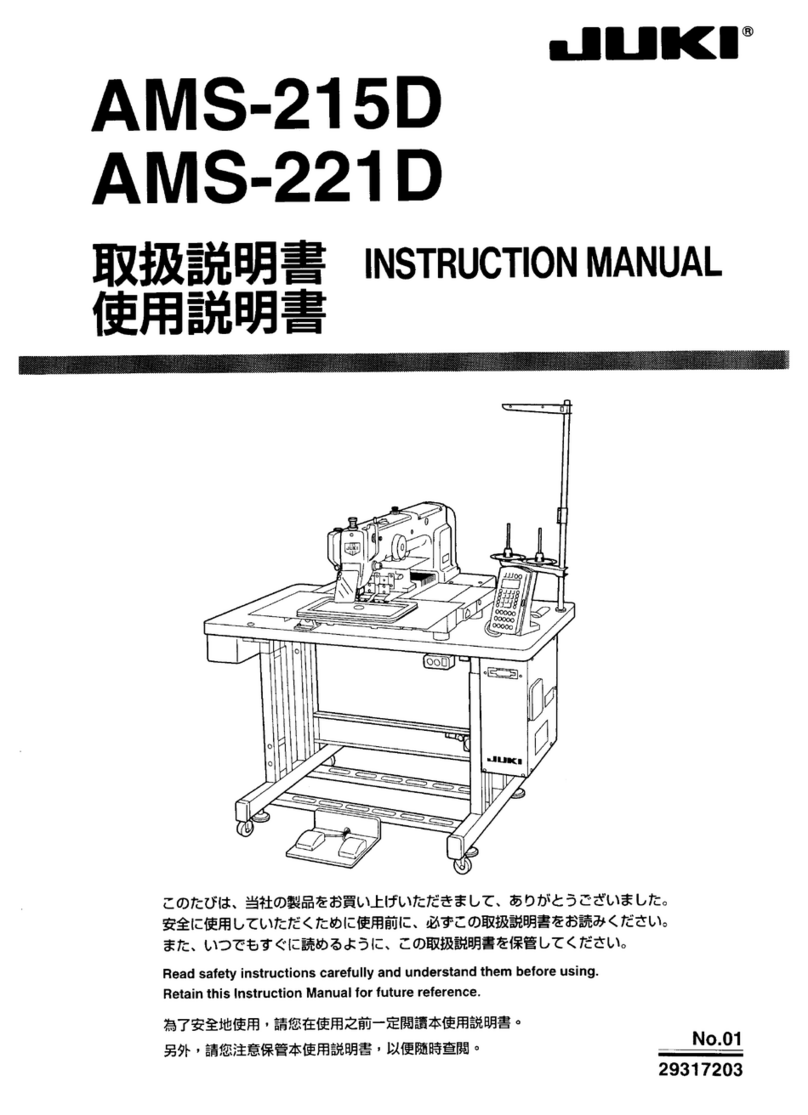

2NAME OF EACH COMPONENT ..................................................... 2

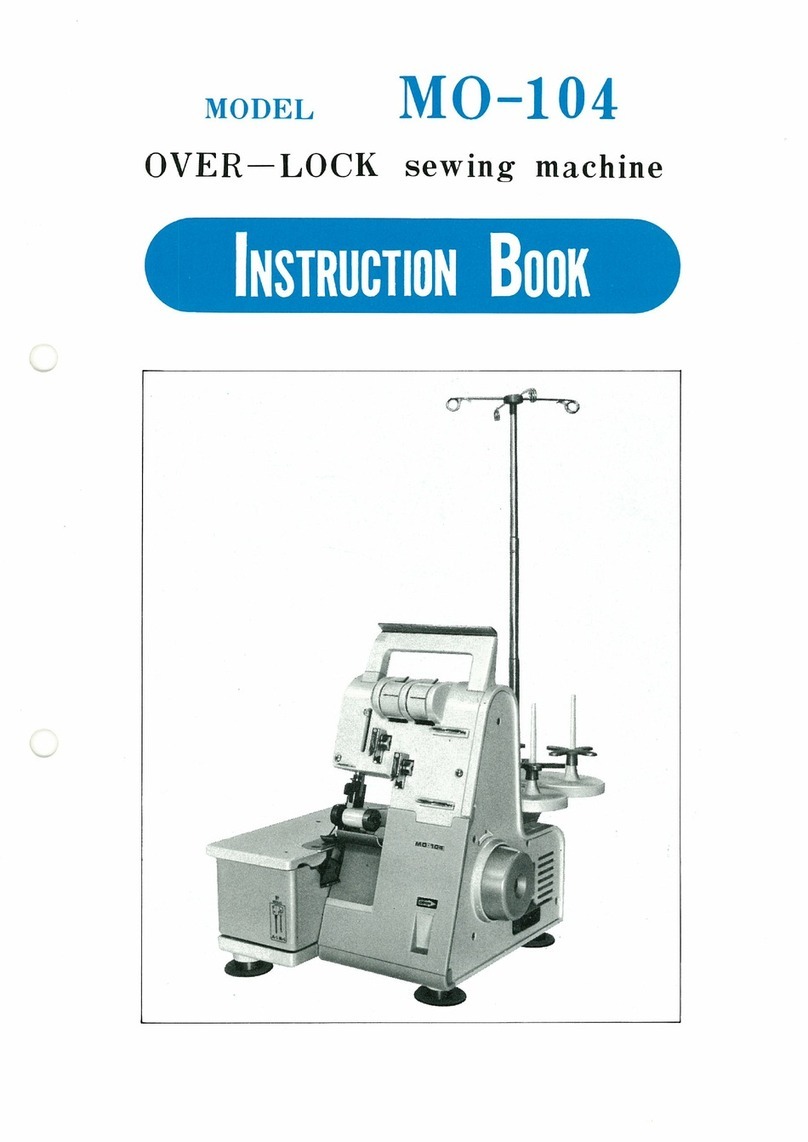

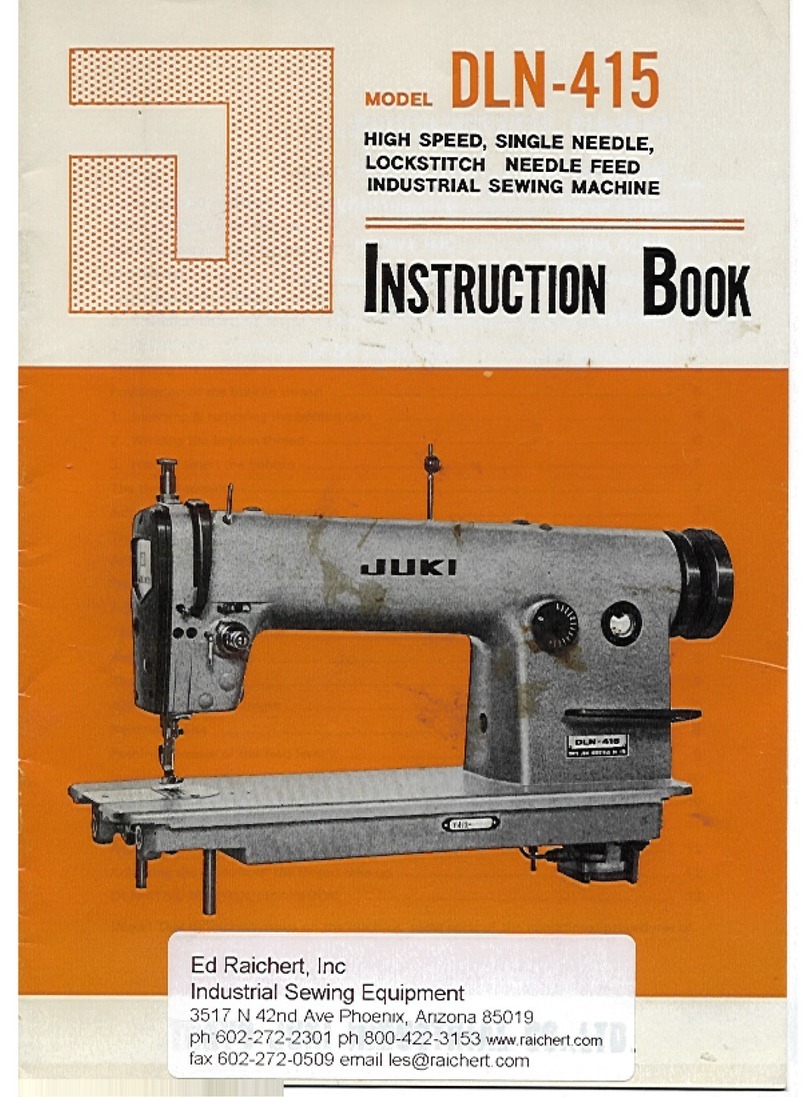

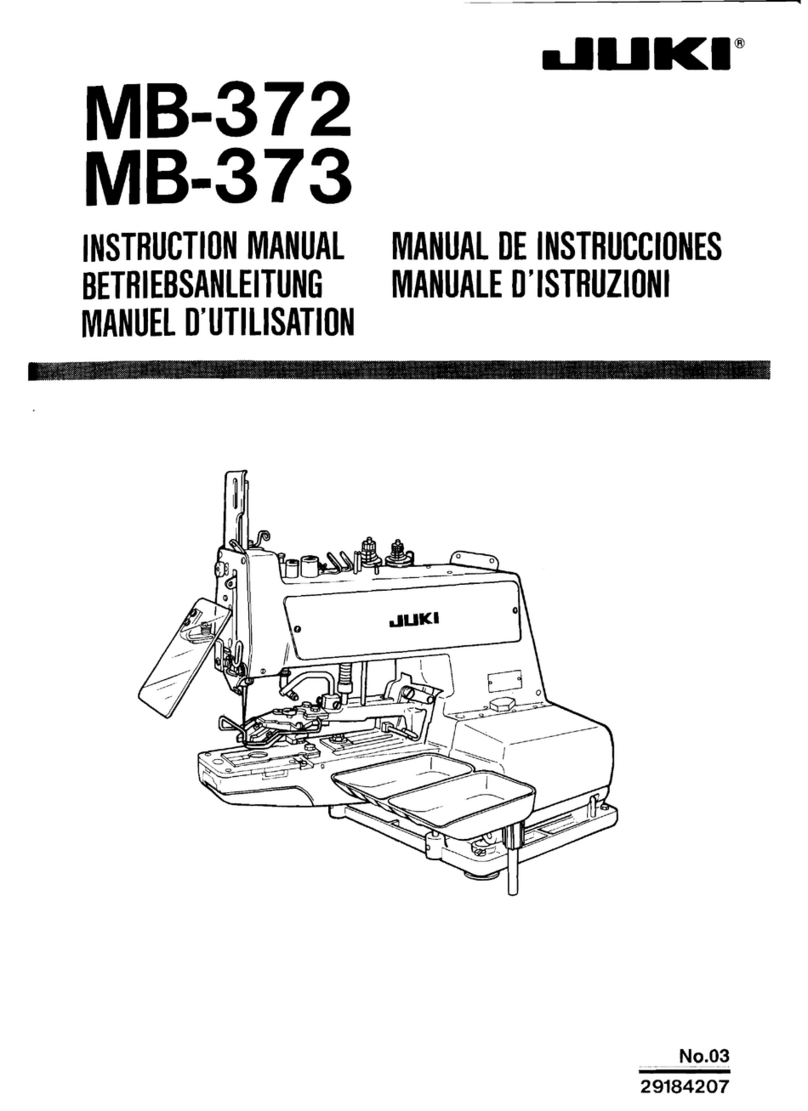

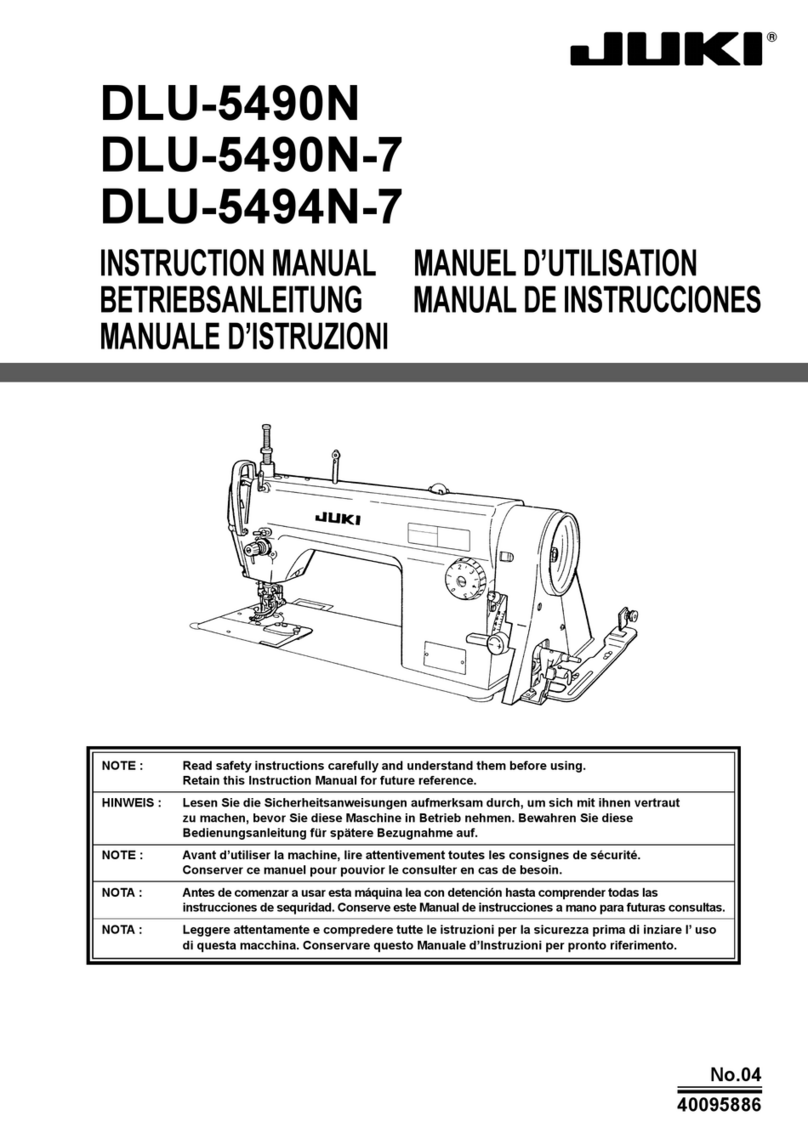

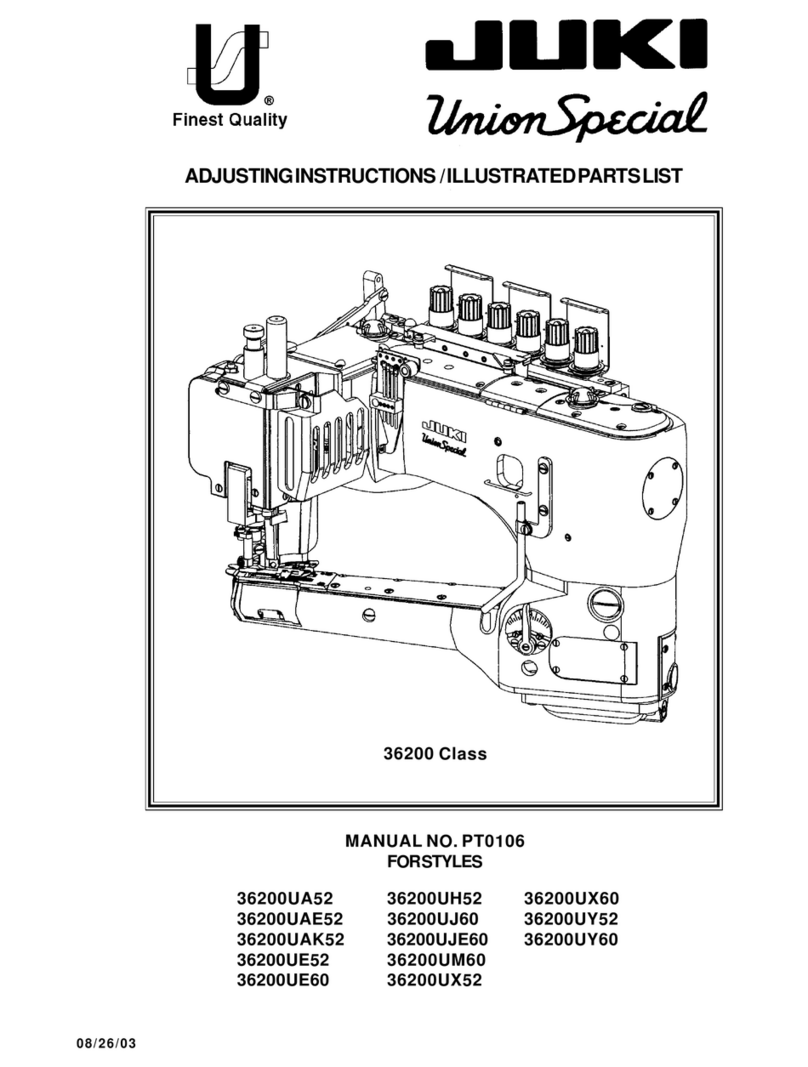

1. Appearance ............................................................................................................... 2

2. Inside of the cover.................................................................................................... 3

3STANDARD ADJUSTMENT / DISASSEMBLY AND ASSEMBLY... 4

1. Removing order of covers....................................................................................... 4

2. Installation of the throat plate ................................................................................. 8

3. Height of the needle bar......................................................................................... 10

4. Position of the feed dog......................................................................................... 12

5. Adjusting the stroke of the sub feed dog............................................................. 14

6. Height of the feed dog............................................................................................ 16

7. Feed dog timing...................................................................................................... 18

8. Position of the balance weights and the cams.................................................... 20

9. Projecting amount of the upper looper ................................................................ 22

10. Radius of the lower looper .................................................................................... 24

11. Adjustment of the loop lift ..................................................................................... 26

12. Timing between upper and lower looper.............................................................. 28

13. Installation of the needle guards .......................................................................... 30

14. Adjusting the looper thread take-up..................................................................... 32

15. Height and lateral position of the presser foot.................................................... 34

16. Adjusting the oating of the disk of the thread tension controller ................... 36

17. Adjusting the tension of the thread tension controller....................................... 38

18. Position of the needle thread take-up thread guide............................................ 40

19. Tension of the belt.................................................................................................. 42

20. Adjusting the needle bar connection guide of the needle threader .................. 44

21. Adjusting the needle threader hook ..................................................................... 46

22. Adjusting the looper threader timing ................................................................... 48

23. Adjusting the pump unit ........................................................................................ 50

24. Position of the lower knife..................................................................................... 52

25. Engagement of the upper knife with the lower knife .......................................... 54