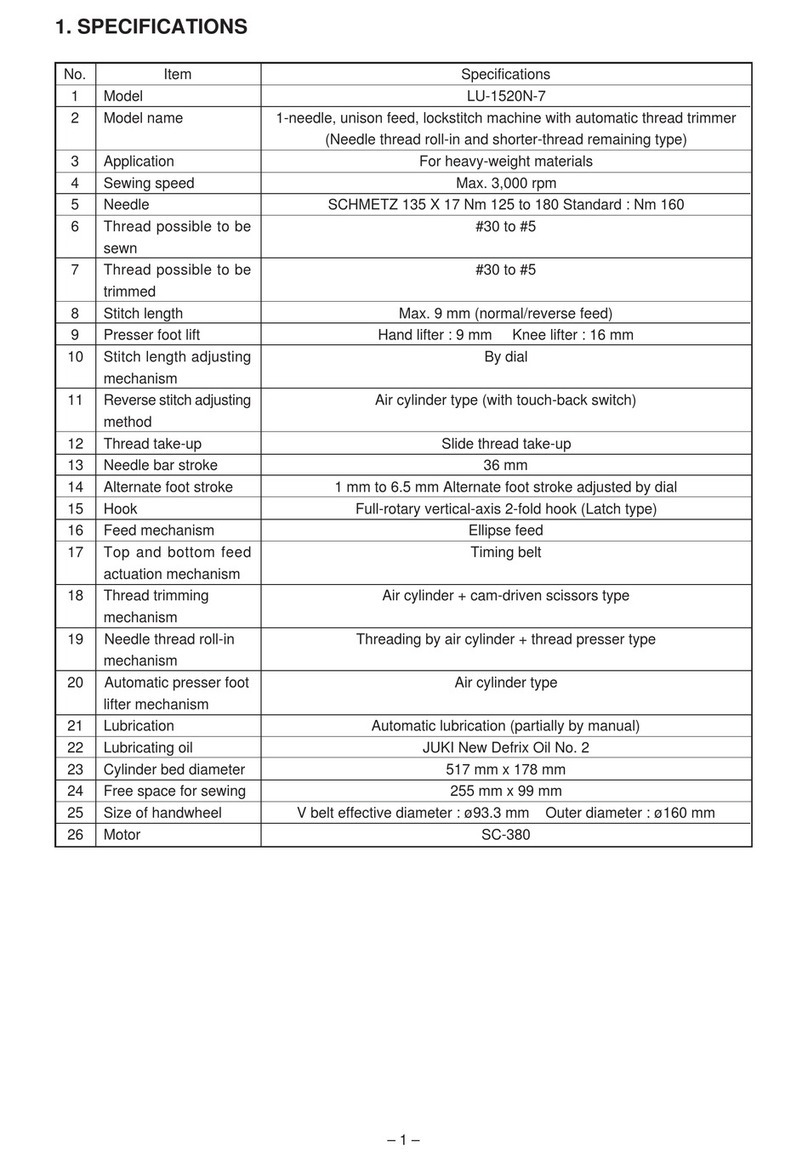

Possibletroubles and phenomena caused by

Improper

adjustments

(1)

When

sewing

materials whichtend to flutter while

being

stitched, set the

needle

bar

slightly

lower

than the standard height.

When

sewing

a

heavy-weight

material,

providing

it isnot of a type that tends to flutter, set the

needle bar slightly higher

than

the

standard

height.

(2) When using a synthetic or soft and thin thread

(for example, cotton thread #80), in order to

prevent it from falling down and snagging, do not

allow it to form a large loop.

(3) If

the

shuttle comes closer to

the

needle than

0.05

mm,

they

may touch and scratch each other.

The scratcheson their surfaceswill

damage

a thin

or

synthetic

thread.

If

the

clearance is greater

than

0.1 mm stitch-

skipping

will result.

(4) If

the

shuttle

driver

dosen't

come

into

close

contact

with

the

needle,

the

needle will

bend

backwards.

The

bent

needle

will

hit

the

blade

point

of

the

shuttle

scratching

them

both.

If

this

happens

the

thread

is likely

to

be

broken

or

torn

by

these

scratched

surfaces.

If the needle isonly slightlybent, stitching will not be

affected. If, however, it isbent too much, it may

cause

stitch-skipping.

(5) If

the

clearance between

the

shuttle

driver and

the shuttle isgreater than 0.3 to 0.5 mm (about

1/64"), a noisewill result during operation. If it

is

too

small, a thick thread may fail to be drawn

out

resulting

in

formation

of

a

loose

stitch.

If

the

needle

point

height is set closer to 7 mm

(9/32"), the stitch will be tightly formed. Whenthe

needle point height is set closer to 10 mm

(25/64"),

it prevents synthetic needle thread from coming

out

on

the

surface of

the

material and forming an idle

loop on

the

first stitch. (No special care is needed for

sewing heavy-weight material)

Corrections

See

"3.

Needle Bar

Components"

in

the

Parts Book.

Remove

the

face plate and adjust

the

needle bar

height

by

loosening

screw

(SS-6090670-TP)

of

needle

bar

connection.

See

"5.

Shuttle

Driver

Shaft

Components" in

the

Parts

Book.

Loosen screw (SS-6121212-TP) and adjust

the

shuttle

driver.

See "5. Shuttle

Driver

Shaft Components" in the

Parts

Book.

Loosen screw (SS-6151220-SP)

to

set free

shuttle

race and adjust

the

shuttle race position in

the

axial

direction by turning shuttle raceadjustingshaft

(B1819-280-000)

Loosen screw (SS-6121212-TP) and adjust shuttle

driver in

the

axial direction by taking care not to

turn

the shuttle driver in

the

direction of rotation. If you

mistakenly allow the shuttle driver to rotate, readjust

the

shuttle

according

to

2).

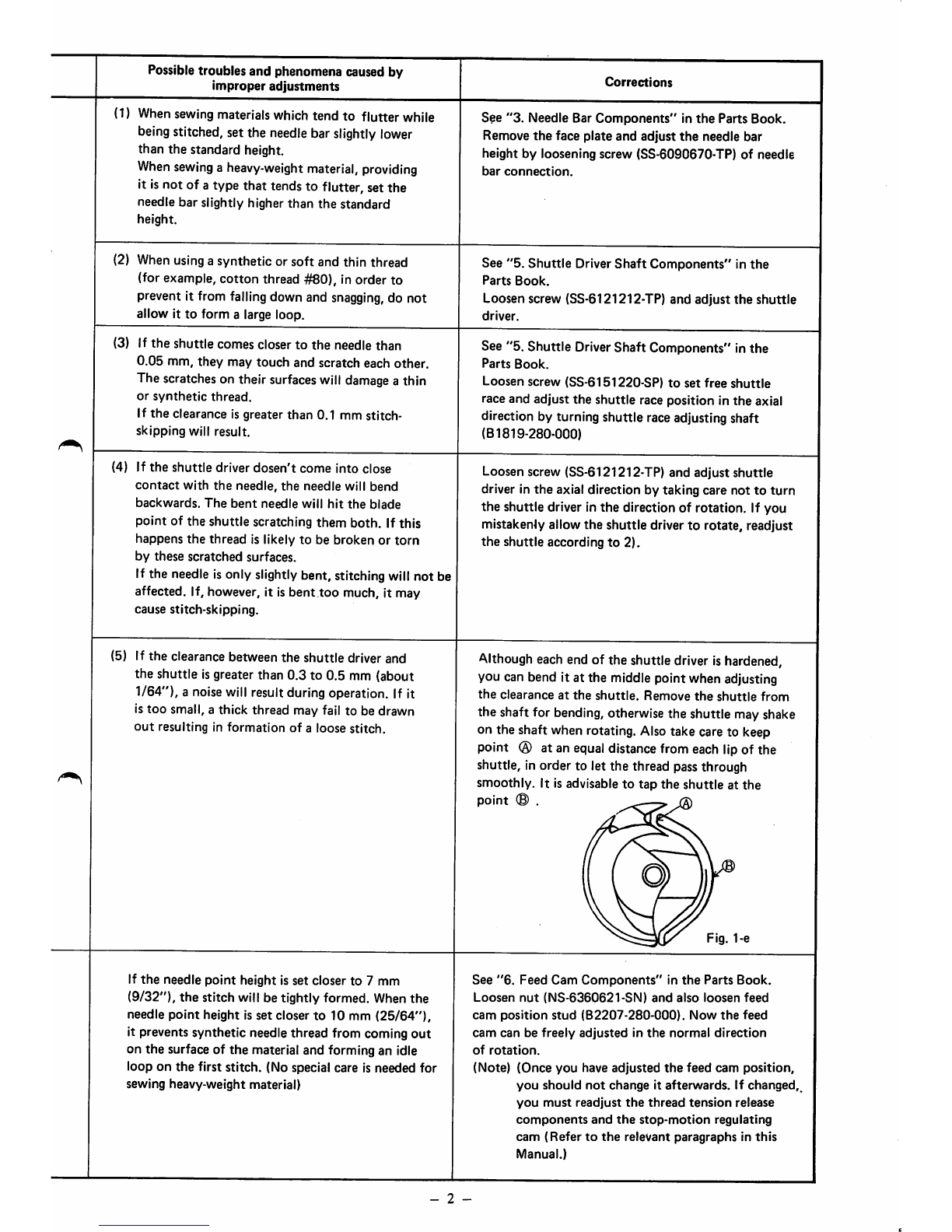

Although

eachend of the shuttledriverishardened,

you can bend it at the middle point when adjusting

the

clearance

at

the

shuttle.

Remove

the

shuttle

from

the shaft for

bending,

otherwise the shuttle mayshake

on the shaft when rotating. Alsotake care to keep

point

(3)

at an

equal

distancefrom each lipof the

shuttle, in order to let the thread passthrough

smoothly. It is advisable

to

tap

the

shuttle

at

the

point © .

Fig. 1-e

See

"6.

Feed

Cam

Components"

in

the

Parts

Book.

Loosen

nut

(NS-6360621-SN)

and

also

loosen

feed

cam

position

stud

(B2207-280-000).

Now

the

feed

cam

can

be

freely

adjusted

in

the

normal

direction

of

rotation.

(Note)

(Once

you

have

adjusted

the

feed

cam

position,

you

should

not

change

it

afterwards.

If

changed,

you

must

readjust

the

thread

tension

release

components

and

the

stop-motion

regulating

cam

(Refer

to

the

relevant

paragraphs

in

this

Manual.)

- 2 -