Be sure to observe the following to protect against a re, electrical shock, injury or damaged components.

* Be sure to unplug the machine before disassembly, assembly or adjustment of the machine.

* Be sure to carefully prevent electric cords from being caught, coated surfaces from being damaged

as well as wrong wiring during assembly.

* Be sure to use the proper genuine parts when changing any of the machine parts.

CAUTION:

CONTENTS

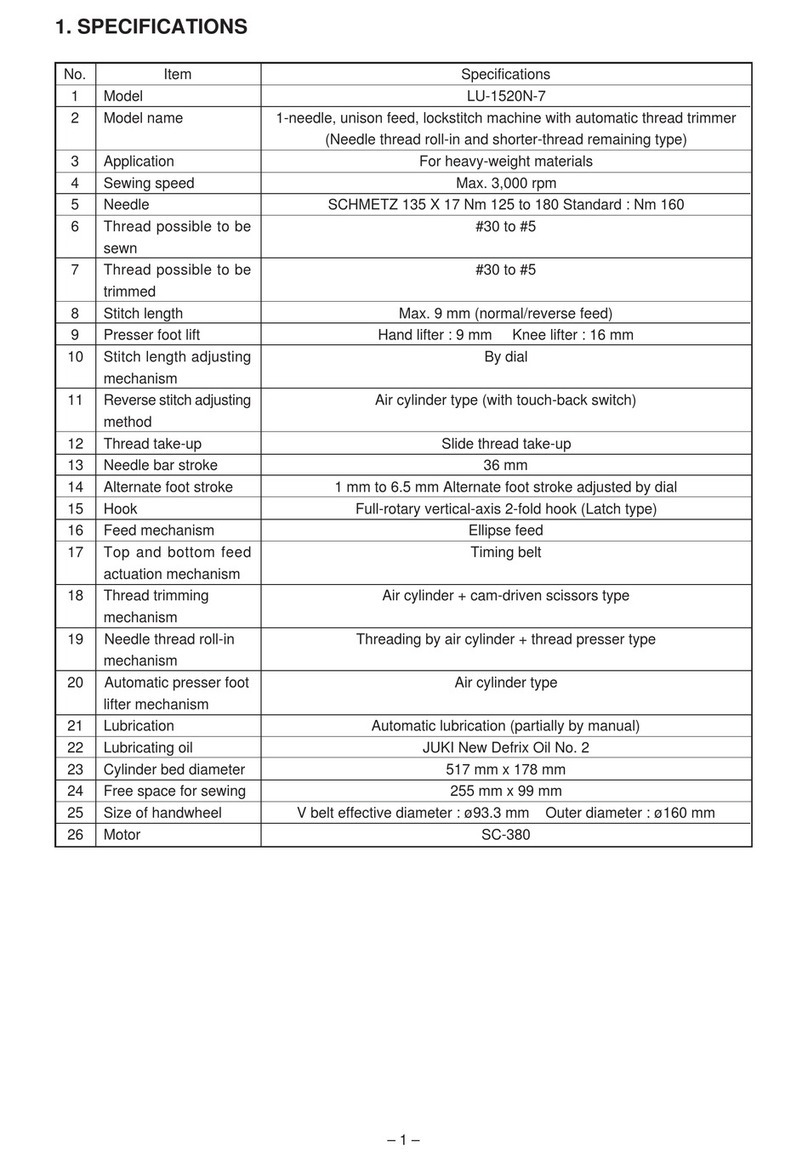

[1] Specications of HZL-NX7 ...................................................................................1

[2] Search by trouble (related to mechanical components) ...................................3

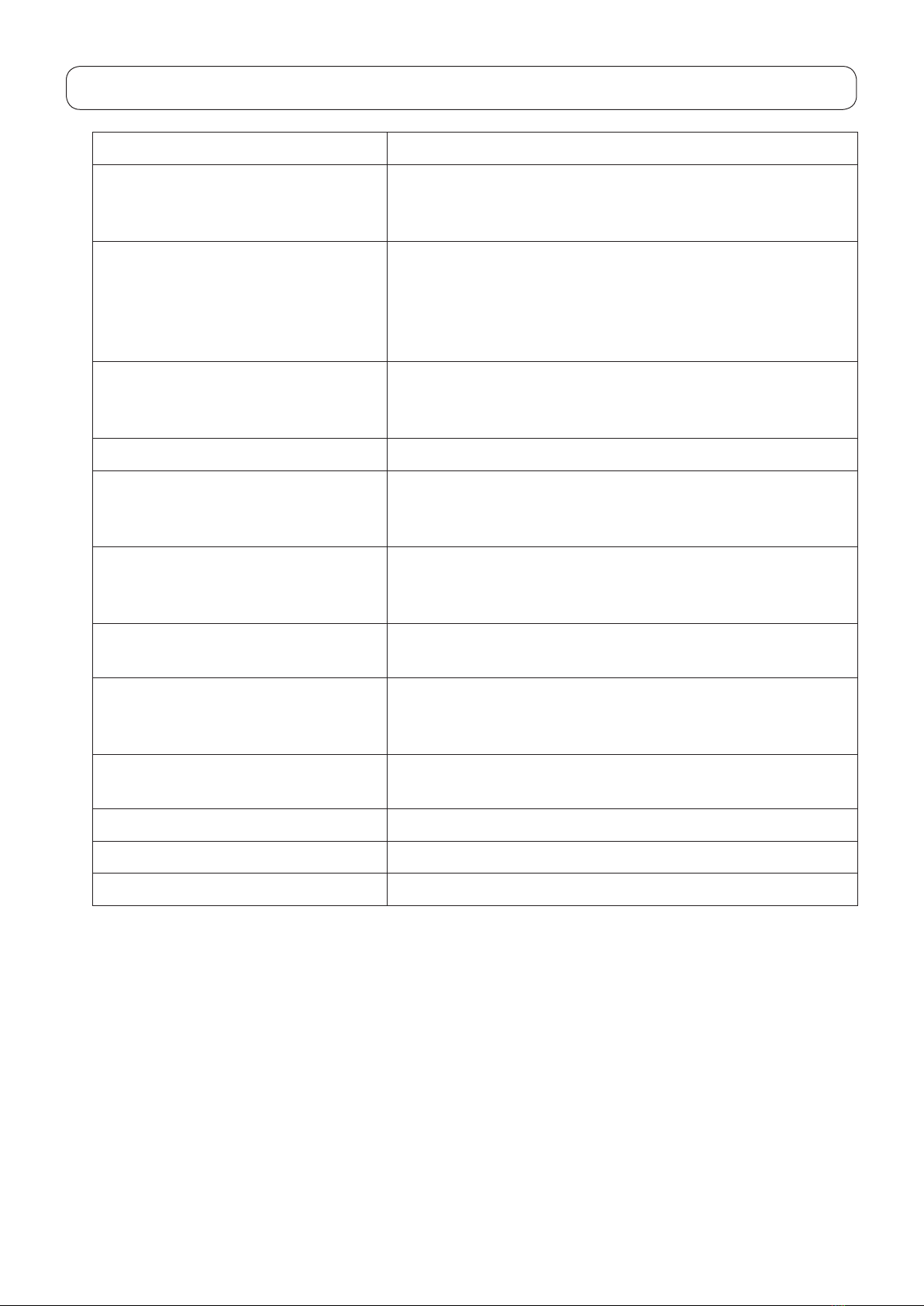

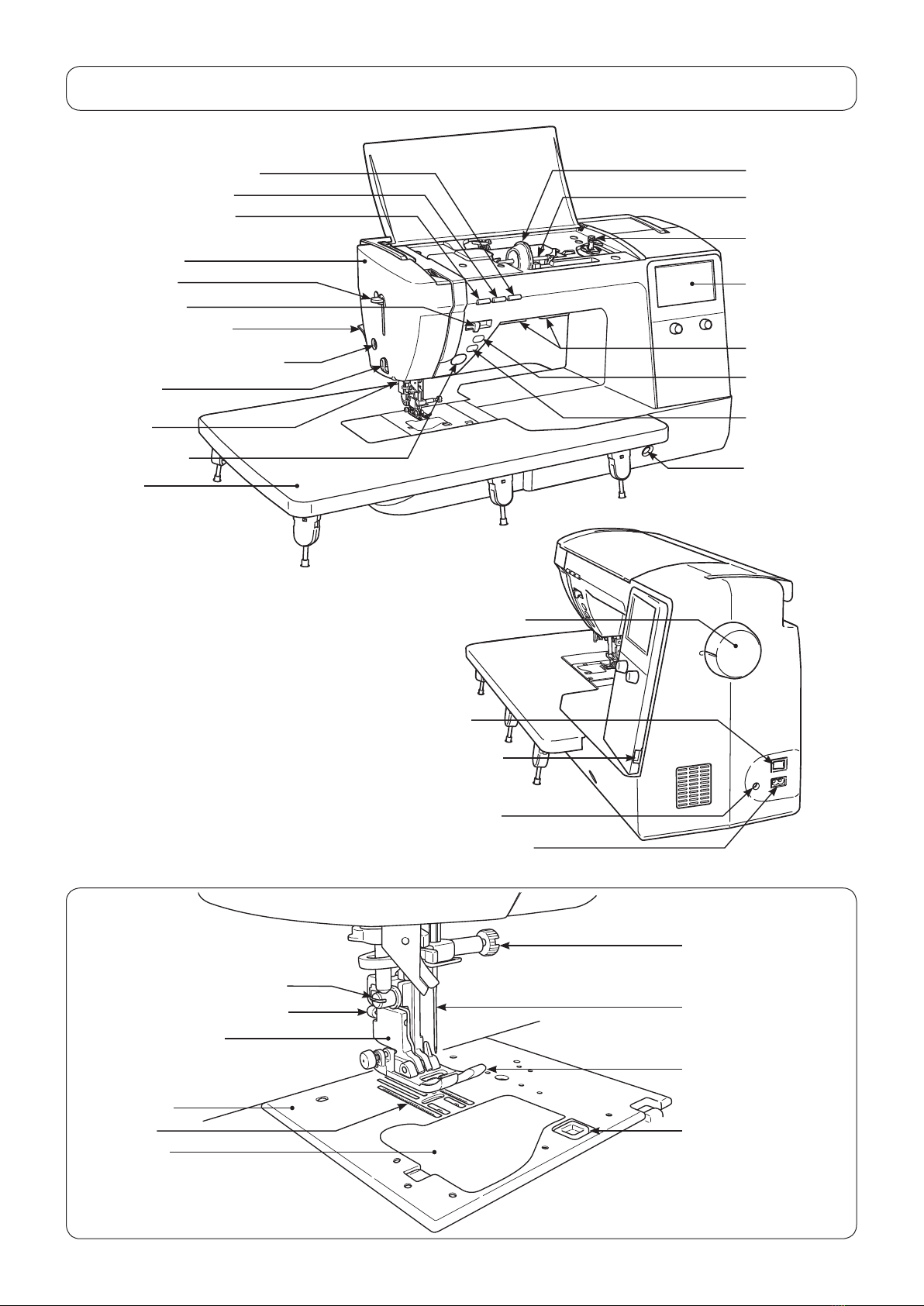

[3] Principal parts .......................................................................................................4

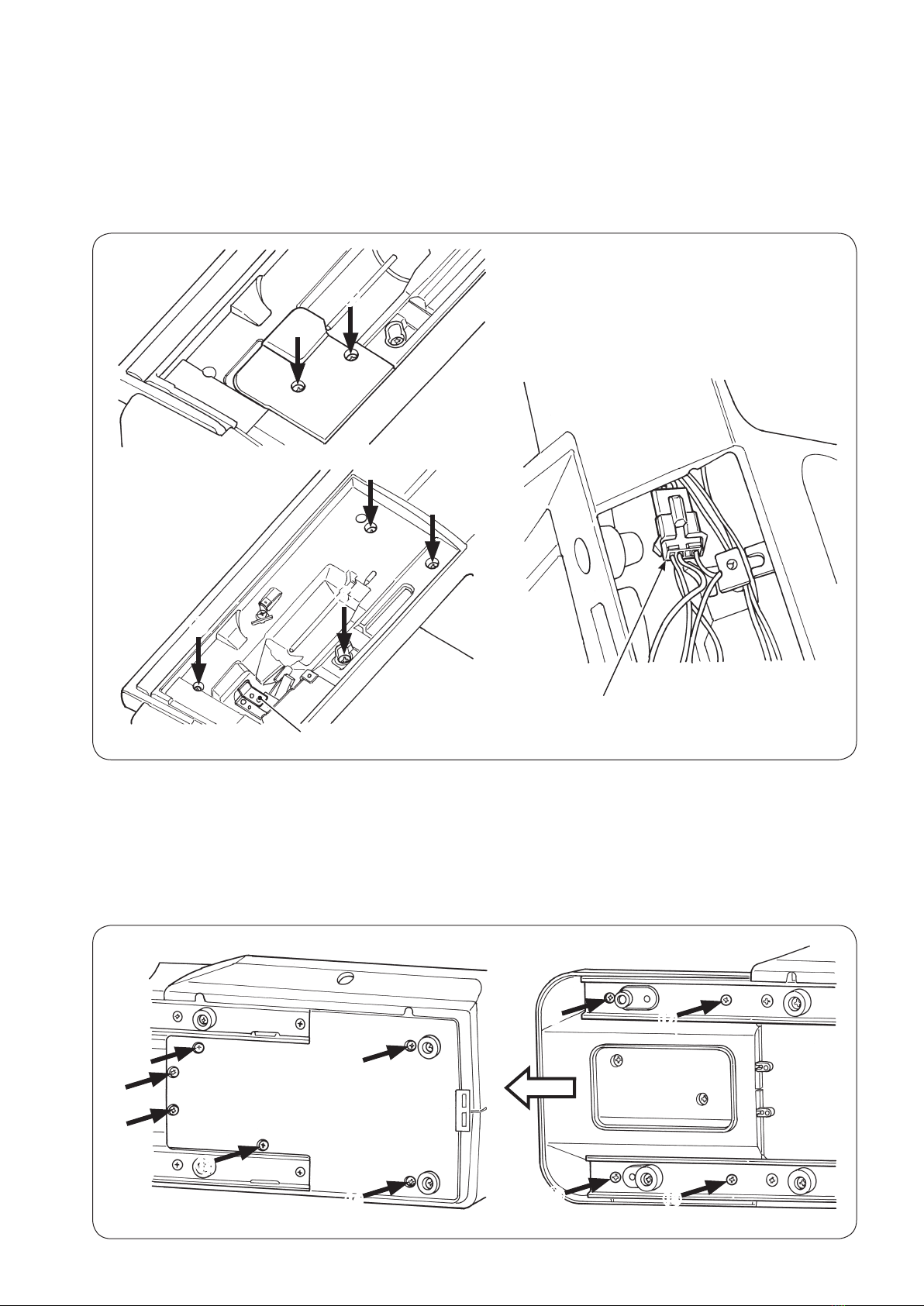

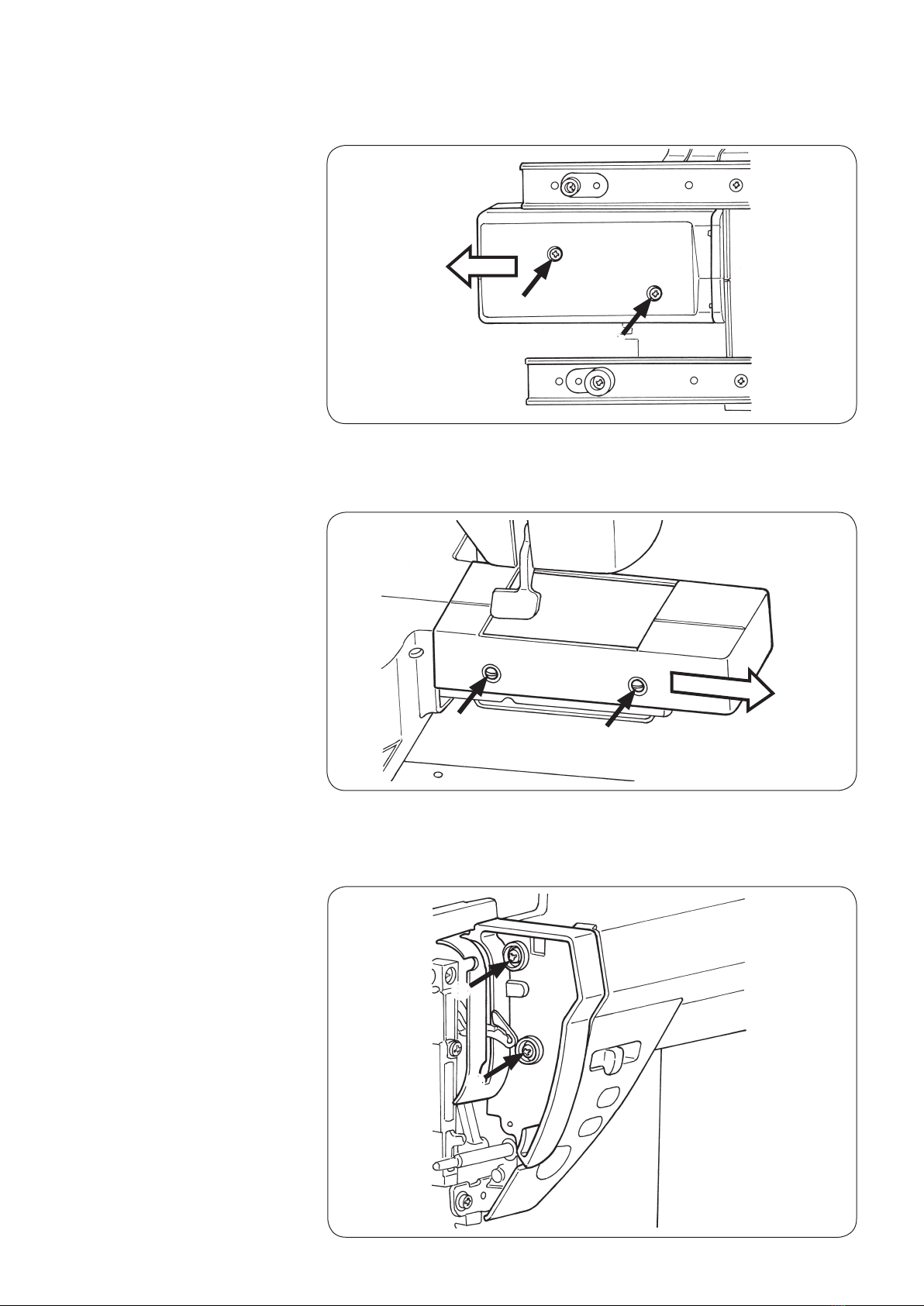

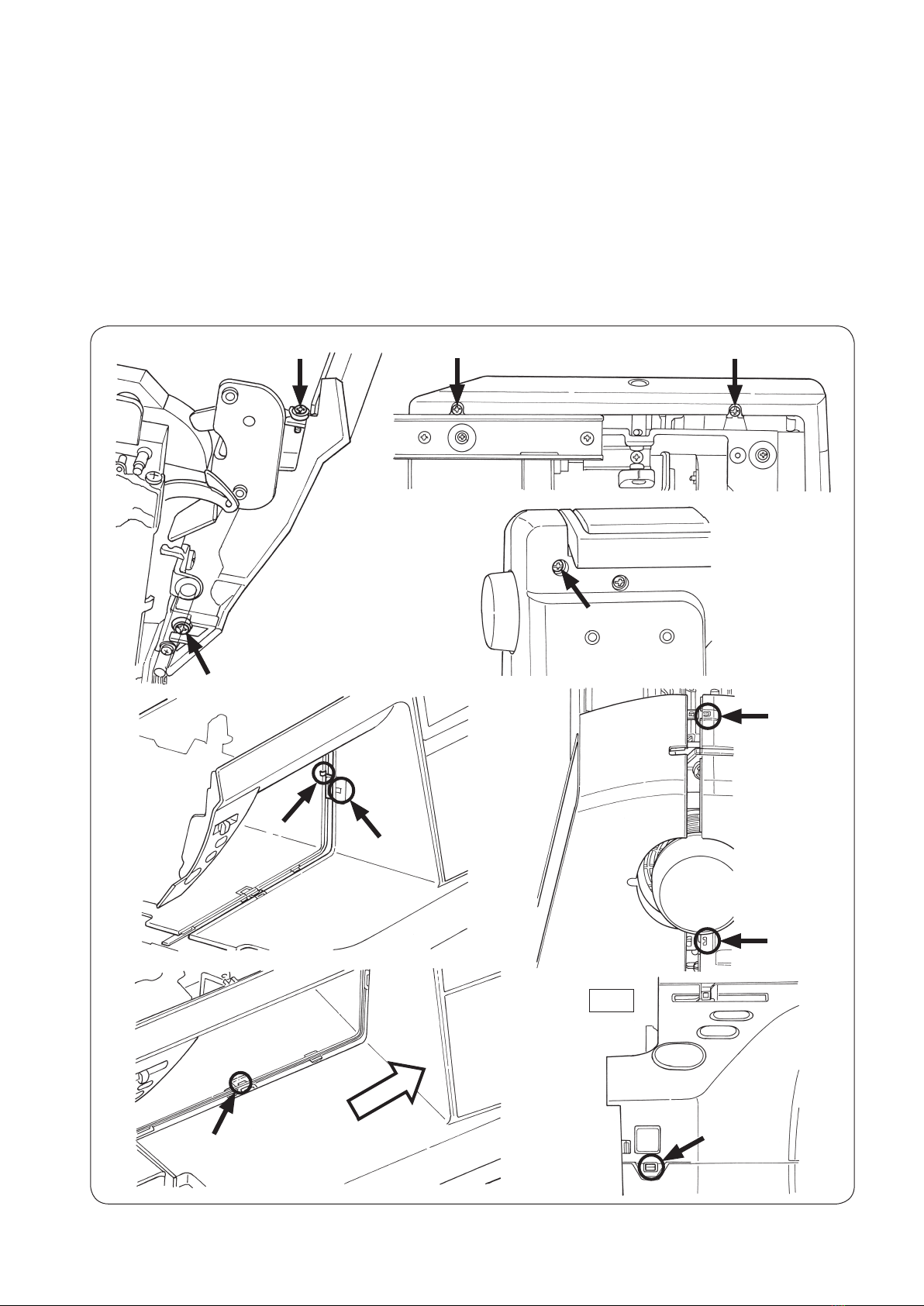

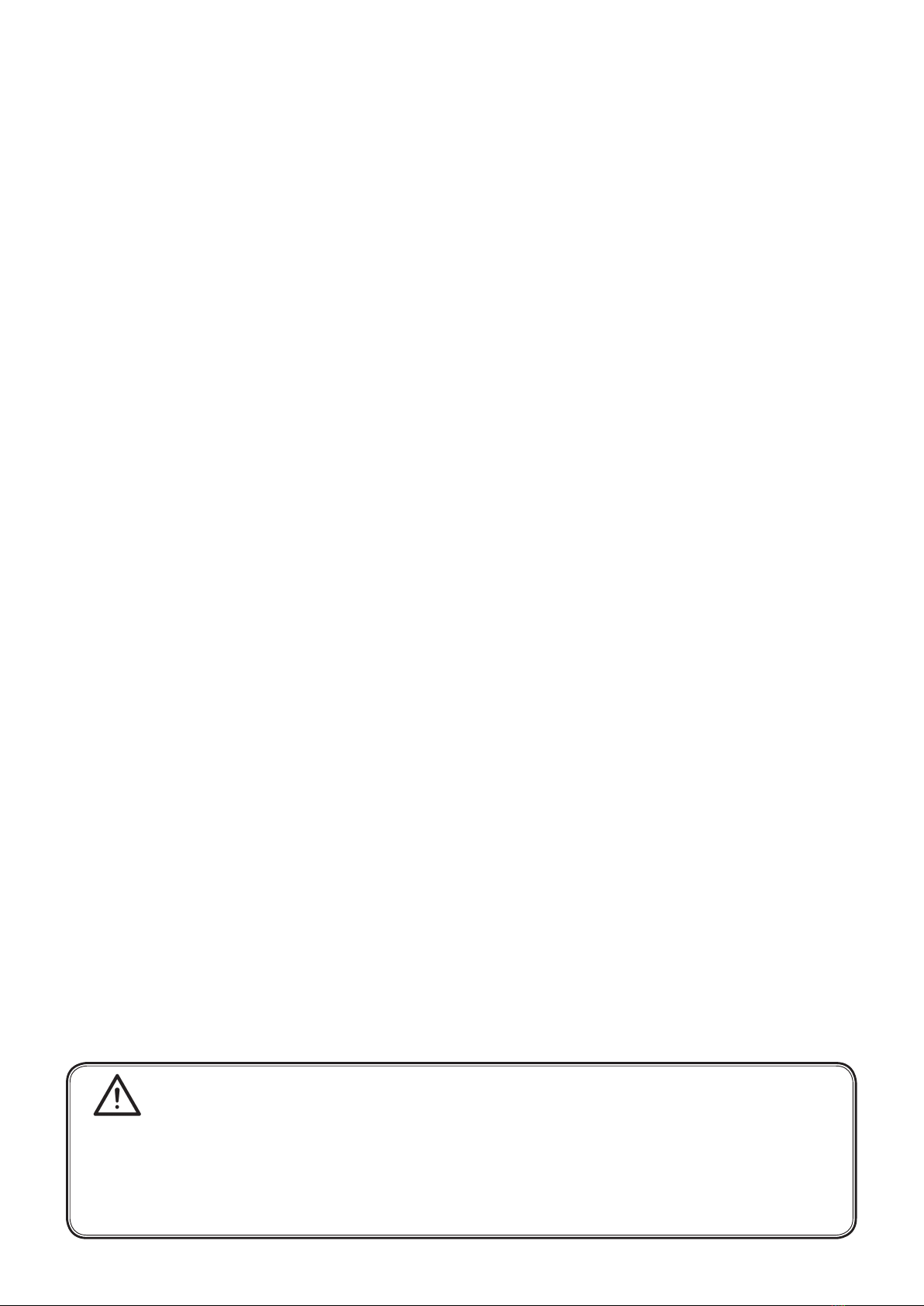

[4] Disassembling the machine covers ....................................................................5

[5] PCB connection diagram ...................................................................................10

[6] Adjustment ..........................................................................................................14

6-1 Adjusting the needle bar height ................................................................14

6-2 Adjusting the needle entry point ...............................................................15

6-3 Feed dog height ..........................................................................................16

6-4 Timing belt ...................................................................................................17

6-5 Feed timing ..................................................................................................17

6-6 Adjusting the shield ....................................................................................18

6-7 Hook driving shaft coupling and the lateral timing of the hook driving

shaft .............................................................................................................19

6-8 Timing between the needle and the hook .................................................20

6-9 Clearance between the needle and the blade point of hook ...................21

6-10 Position of the hook rotation stopper plate ...........................................22

6-11 Adjusting the bobbin thread tension .......................................................22

6-12 Adjusting the needle thread tension .......................................................23

6-13 Vertical position of the needle threading hook ......................................24

6-14 Adjusting the auxiliary hook height ........................................................25

6-15 Adjusting the opening amount of auxiliary hook ...................................26

6-16 Adjusting the presser bar height .............................................................26

6-17 Motor belt ...................................................................................................27

6-18 Longitudinal feed ......................................................................................28

6-19 Presser foot lifting ....................................................................................29

6-19-1 Position of the presser foot lifting motor .......................................29

6-19-2 Adjusting the height of the auto-lifter .............................................30

6-20 Thread trimming ........................................................................................31

6-20-1 Attaching/removing the thread trimmer unit ..................................31

6-20-2 Adjusting the thread trimming switch .............................................32

6-21 Attaching/removing the top feed dog .....................................................33

6-22 Position of the automatic DF motor ........................................................34

6-23 Service mode .............................................................................................35

6-23-1 Service mode screen ........................................................................35

6-23-2 Service-mode items and descriptions ............................................35