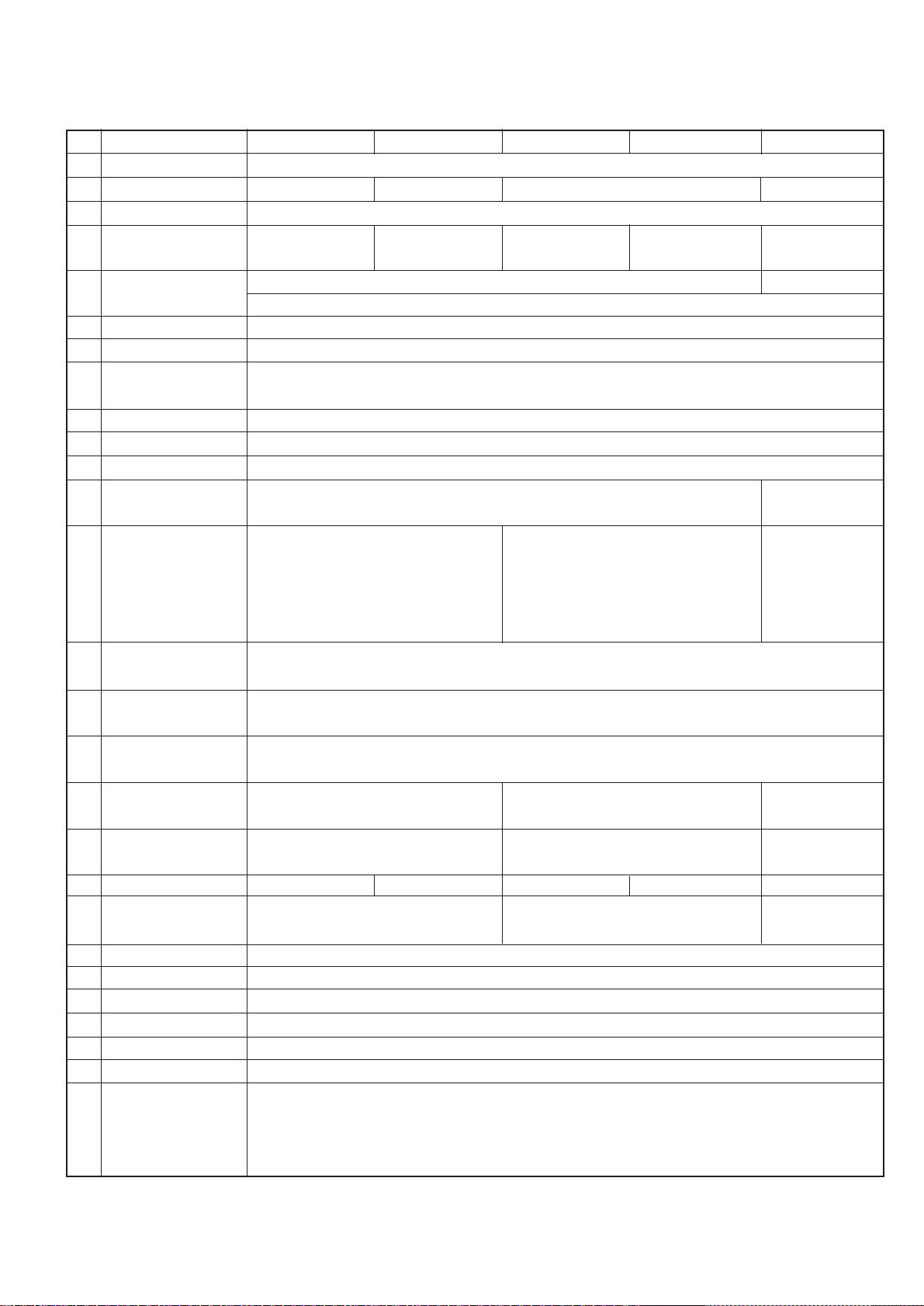

CONTENTS

1. SPECIFICATIONS .......................................................................................................... 1

(1) Specifications of the machine head...................................................................................................... 1

(2) Stitch pattern table................................................................................................................................ 2

(3) Function list .......................................................................................................................................... 3

(4) Cautions in operation............................................................................................................................ 4

2. NAME OF EACH COMPONENT .................................................................................... 4

3. STANDARD ADJUSTMENT .......................................................................................... 6

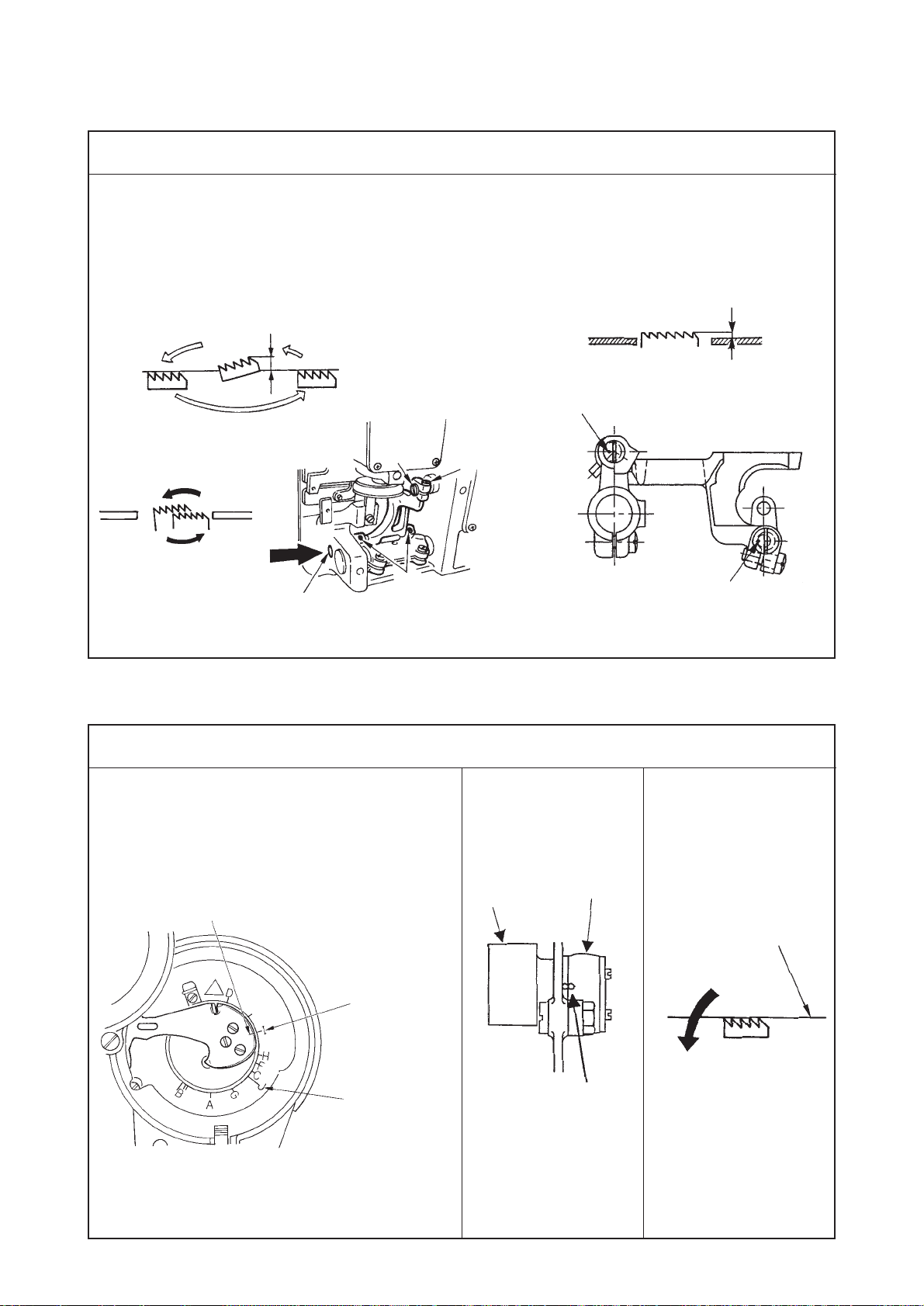

(1) Height and inclination of the feed dog .................................................................................................. 6

(2) Adjusting the feed timing ...................................................................................................................... 6

1) Adjusting the feed timing (Excluding A-SR).................................................................................... 6

2) Adjusting the feed timing (for A-SR only) ....................................................................................... 8

(3) Adjusting the feed amount.................................................................................................................. 10

1) Adjusting the feed amount (Excluding A-SR) ............................................................................... 10

2) Adjusting the feed amount (A-SR only) ........................................................................................12

(4) Position of the feed dog...................................................................................................................... 14

(5) Adjusting the slippage of materials (For A-SU and A-DU).................................................................. 16

(6) Adjusting the origin of the needle rocking motor ................................................................................ 18

(7) Adjusting the needle entry position (In terms of needle rocking direction) ......................................... 20

(8) Adjusting the needle entry position (In terms of longitudinal direction) .............................................. 20

(9) Adjusting the longitudinal play at the needle bar ................................................................................ 20

(10) Position of the needle bar connection guide..................................................................................... 22

(11) Height of the needle bar ................................................................................................................... 22

(12) Adjusting the needle-to-hook timing and the needle guard .............................................................. 24

(13) Position of the bobbin case stopper ................................................................................................. 26

(14) Orientation of the needle bar thread holder...................................................................................... 26

(15) Position of the thread tension ........................................................................................................... 28

(16) Position of the pre-tension................................................................................................................ 28

(17) Position of the thread take-up spring guard...................................................................................... 30

(18) Installing the thread take-up thread guide B..................................................................................... 30

(19) Installing the thread take-up ............................................................................................................. 30

(20) Installation of the presser foot .......................................................................................................... 32

(21) Installing and adjusting the bobbin winder unit................................................................................. 32

(22) Adjusting the amount of oil in the hook (A-SS/-7, A-SU/-7, A-SR) ................................................... 34

(23) Adjusting the thread trimming unit (Thread trimmer type only)......................................................... 36

(24) Initial position of the moving knife (Thread trimmer type only) ......................................................... 36

(25) Timing of the thread trimming cam (Thread trimmer type only)........................................................ 38

(26) Installing/removing the knife unit (Thread trimmer type only)........................................................... 38

(27) Stop position of the needle after thread trimming (Needle UP stop) ................................................ 38

(28) Clearance provided between the main shaft handwheel and the stator........................................... 40

(29) Position of the automatic reverse stitching magnet (Excluding A-SR) ............................................. 40

(30) Adjusting the thread tension releasing solenoid (Thread trimmer type only).................................... 40

(31) Adjusting the stitch length dial (Excluding A-SR) ............................................................................. 42

(32) Adjusting the lubrication mechanism (A-SS and A-SU, A-SR only) ................................................. 44

(33) Adjusting the position of the thread draw-out wire

(For the machine with thread trimmer only) ......................................................................................44

(34) Adjusting the stroke of the thread draw-out wire

(For the machine with thread trimmer only) ......................................................................................46

(35) Installing the wiper base (WB type only) .......................................................................................... 46

(36) Adjusting the wiper solenoid (WB type only) .................................................................................... 48

(37) Position of the wiper ......................................................................................................................... 48

1) WB type ........................................................................................................................................ 48

2) CB type......................................................................................................................................... 50